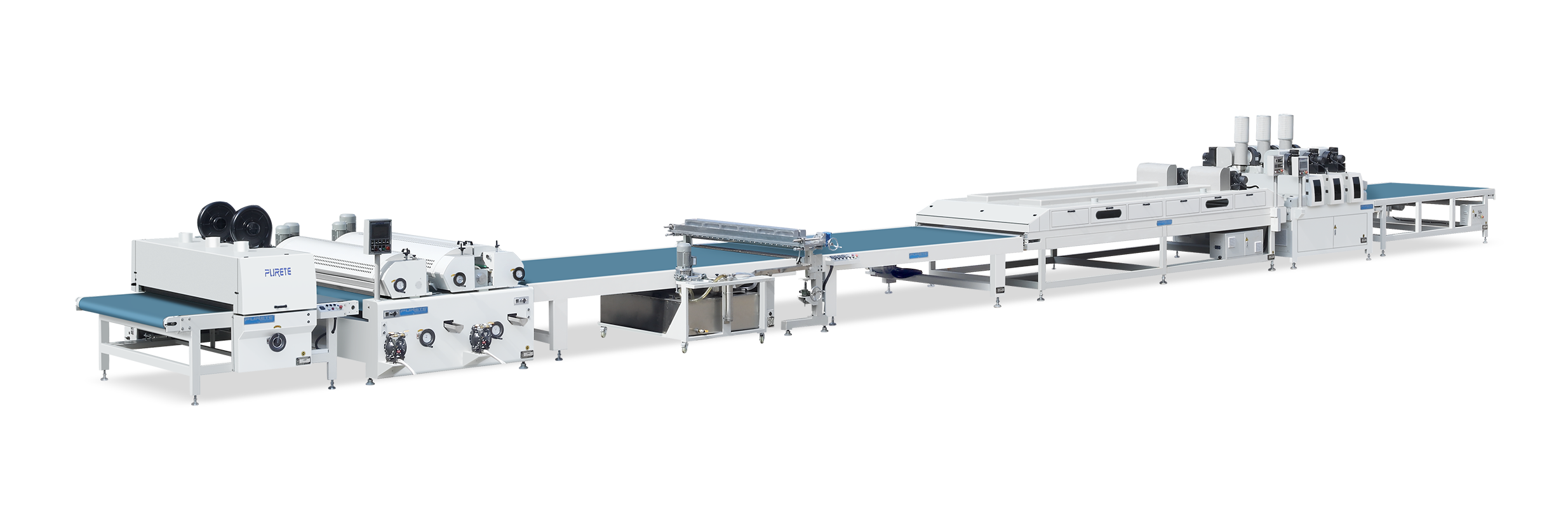

L10A Curtain Coating Production Line for UV High-Gloss Finishes

The L10A curtain coating production line is a multifunctional UV high-gloss coating system designed for mirror-surface plate finishing. It delivers exceptional surface smoothness and a striking mirror highlight effect. The UV coating produces a rich, vibrant color with strong environmental performance — featuring excellent scratch resistance, acid and alkali resistance, and corrosion protection. The coated surface maintains its brilliance over time, with no fading or deformation, even after long-term exposure.

This advanced line is composed of a dust cleaner, combined filling and roller coating machine, curtain coater, 12-meter IR heating oven, and a three-lamp UV curing system. Ideal for decorative panels, furniture boards, and high-end interior materials, the L10A ensures consistent coating quality, durable protection, and efficient automated production.

Read more

L10A-1950 Curtain Coating Production Line for Wide High-Gloss Panels

The L10A-1950 curtain coating production line is specially designed for wide-format, large-scale substrates that require premium high-gloss surface finishing. It is ideal for coating materials such as marble-effect panels, melamine (three-amine) boards, and other decorative wall panels. This advanced system delivers a mirror-like finish with exceptional smoothness, brilliance, and durability—perfect for high-end interior decoration applications.

The complete line is composed of a dust cleaner, forward and reverse coater, curtain coater, 12-meter IR heating oven, and a three-lamp UV curing unit. Engineered for industrial-scale production, the L10A-1950 offers stable coating performance, consistent quality, and excellent efficiency, meeting the demands of modern architectural and decorative panel manufacturing.

Read more