The Comprehensive Guide to Curtain Coating Machines

February 28, 2025

February 28, 2025 Hits:2275second

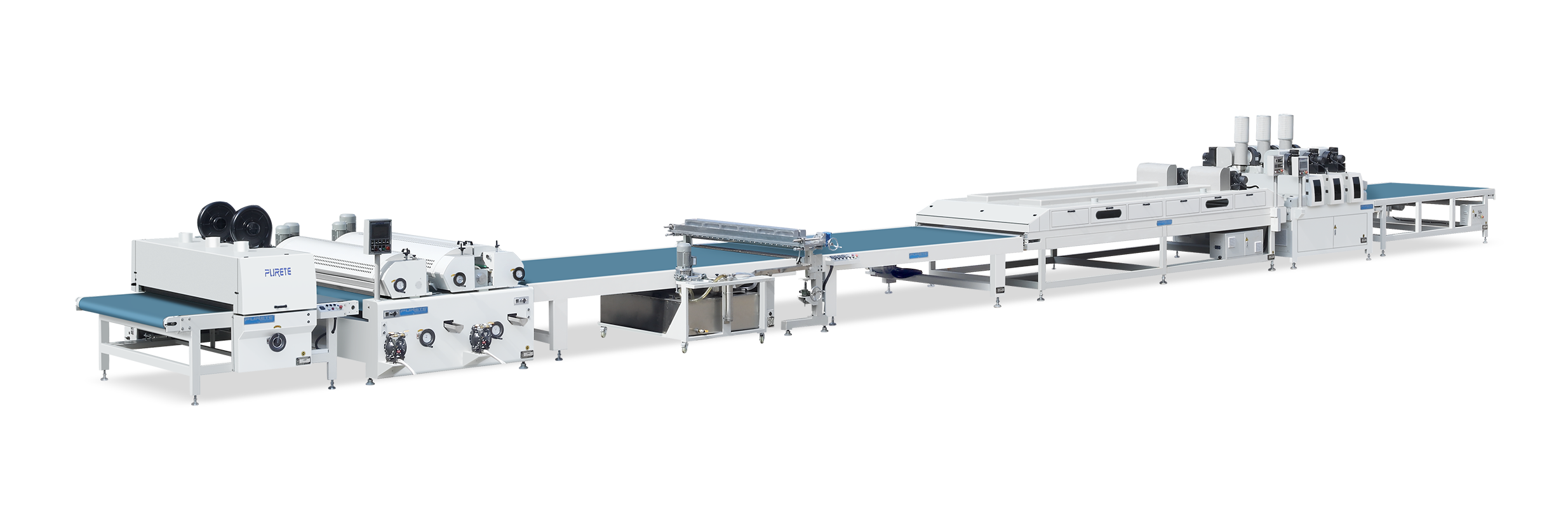

Hits:2275secondA curtain coating machine is a specialized piece of equipment designed to apply a uniform liquid layer onto a substrate. This coating technology is widely used in paper manufacturing, film production, textile finishing, and electronic component fabrication, where precise and consistent coating applications are critical. Compared to other coating methods, the curtain coating process stands out for its ability to deliver high-quality, continuous coatings with excellent efficiency and reduced waste.

Working Principle of Curtain Coating Machines

The curtain coating process operates by forming a continuous curtain of liquid material that falls onto a moving substrate. The substrate, which may be paper, plastic film, fabric, or other materials, passes underneath this curtain at a controlled speed.

Key factors influencing coating quality include:

Liquid Flow Control – precise adjustment ensures uniform thickness.

Substrate Speed – synchronization avoids streaks or uneven layers.

Curtain Height – distance between nozzle and substrate defines coating stability.

This principle enables continuous coating application at industrial scale, making it ideal for high-speed paper coating machines, liquid coating film equipment, and functional coating materials for films.

Core Components of Curtain Coating Equipment

Reservoir Tank

Holds the liquid coating material. Advanced systems can handle water-based, solvent-based, and UV-curable coatings.

Curtain Forming Device

A nozzle or slot die that creates the falling liquid curtain. Variants include types of curtain coaters designed for different viscosities and coating applications.

Substrate Handling System

Rollers, guides, and web tension systems ensure stable movement of substrates such as paper, film, or textiles.

Drying Unit

Hot air, infrared, or UV drying solidifies coatings efficiently. In paper coater machines, drying speed is critical for mass production.

Control System

Automation and sensors manage coating thickness, liquid supply, substrate speed, and drying conditions. Modern curtain coater machines integrate advanced PLC systems for accuracy.

Benefits of Using Curtain Coater Machines

Uniform Coating Quality

Guarantees high precision in lacquering curtain coaters for glossy surfaces and functional coatings.

High Efficiency & Speed

Enables continuous industrial coating for large-scale production lines in paper coating equipment and film manufacturing.

Versatility

Supports coatings such as adhesives, varnishes, flame-retardant agents, waterproof layers, and functional barrier coatings for films.

Cost Reduction

By applying only the required material, curtain coaters minimize waste and reduce overall operational expenses.

Sustainability

Advanced OEM curtain coating equipment is designed to minimize emissions, aligning with green manufacturing practices.

Industrial Applications of Curtain Coating Technology

1. Paper and Board Industry

Curtain coaters are used in paper machines to apply varnishes, inks, and functional coatings that enhance printability, durability, and surface appearance.

2. Film Manufacturing

In liquid coating film equipment, curtain coating applies barrier coatings, adhesives, and optical layers, crucial for packaging films, PVD coating applications, and protective laminates.

3. Textile Coating

Textile manufacturers rely on curtain coating type machines for applying waterproof, fire-resistant, and UV-resistant coatings.

4. Electronics Industry

Used to coat substrates for printed circuit boards, electronic laminates, and insulating layers, where precise uniformity is essential.

5. Pharmaceutical Applications

Specialized curtain coating equipment applies protective layers on tablets and capsules, ensuring controlled release and durability.

Types of Curtain Coaters

Single-Curtain Coaters – Standard design for thin, uniform coatings.

Multi-Layer Curtain Coaters – Allow multiple functional coatings in a single pass.

OEM Curtain Coating Machines – Tailored for specific production needs, including factory OEM liquid coating film equipment.

PVD Curtain Coating Systems – Specialized for high-tech applications like supply PVD curtain coating machines for functional films and electronics.

Choosing the Right Curtain Coating Machine Manufacturer

When selecting a curtain coating machine manufacturer, consider:

Experience in paper coating equipment used and film coating systems

Availability of customized curtain coating type machines

Integration of automation and digital monitoring

After-sales support and spare parts availability

Top suppliers often provide OEM continuous coating machines, designed for specific industrial requirements.

Future Trends in Curtain Coating Technology

The next generation of curtain coating machines will focus on:

Smarter automation with AI-driven process control

Enhanced sustainability through solvent-free coatings

Expansion of functional coating materials for films in packaging, medical devices, and electronics

More advanced curtain coating equipment for industrial OEM applications

Conclusion

A curtain coating machine is an indispensable tool for industries requiring precise, uniform, and efficient coatings. From paper machines and film production to textile, electronics, and pharmaceuticals, the technology enables continuous coating application at industrial scale.

By choosing the right curtain coater machine manufacturer and investing in modern curtain coating equipment, businesses can achieve higher efficiency, cost savings, and sustainability while maintaining top-quality product finishes.