Advanced Wood Surface Coating Solutions: From Wrapping Lines to Inert Coating Technology

December 24, 2025

December 24, 2025 Hits:204second

Hits:204secondIn modern furniture manufacturing, surface finishing is no longer just about aesthetics—it plays a critical role in durability, efficiency, and large-scale production consistency. As furniture factories move toward automated, high-output manufacturing models, advanced wood surface coating solutions have become essential for meeting both functional and commercial requirements.

From wrapping production lines designed for complex profiles to inert coating technology enabling ultra-stable curing environments, manufacturers now have access to a wide range of industrial coating systems. Choosing the right solution depends on product type, output volume, surface complexity, and long-term production goals.

This article provides a comprehensive overview of modern wood surface coating technologies, compares their strengths, and explains how integrated solutions from PURETE support efficient, scalable furniture production.

Overview of Wood Surface Coating Technologies

Wood surface coating technologies have evolved significantly over the past decade. Traditional manual spraying and single-machine processes are increasingly replaced by automated coating production lines that deliver consistent quality with minimal labor input.

Common industrial coating technologies include:

Wrapping production lines

Roller coating lines

UV coating systems

Inert coating technology

Integrated surface finishing lines

Each system serves different product categories and production strategies, making it essential for furniture manufacturers to understand their functional differences.

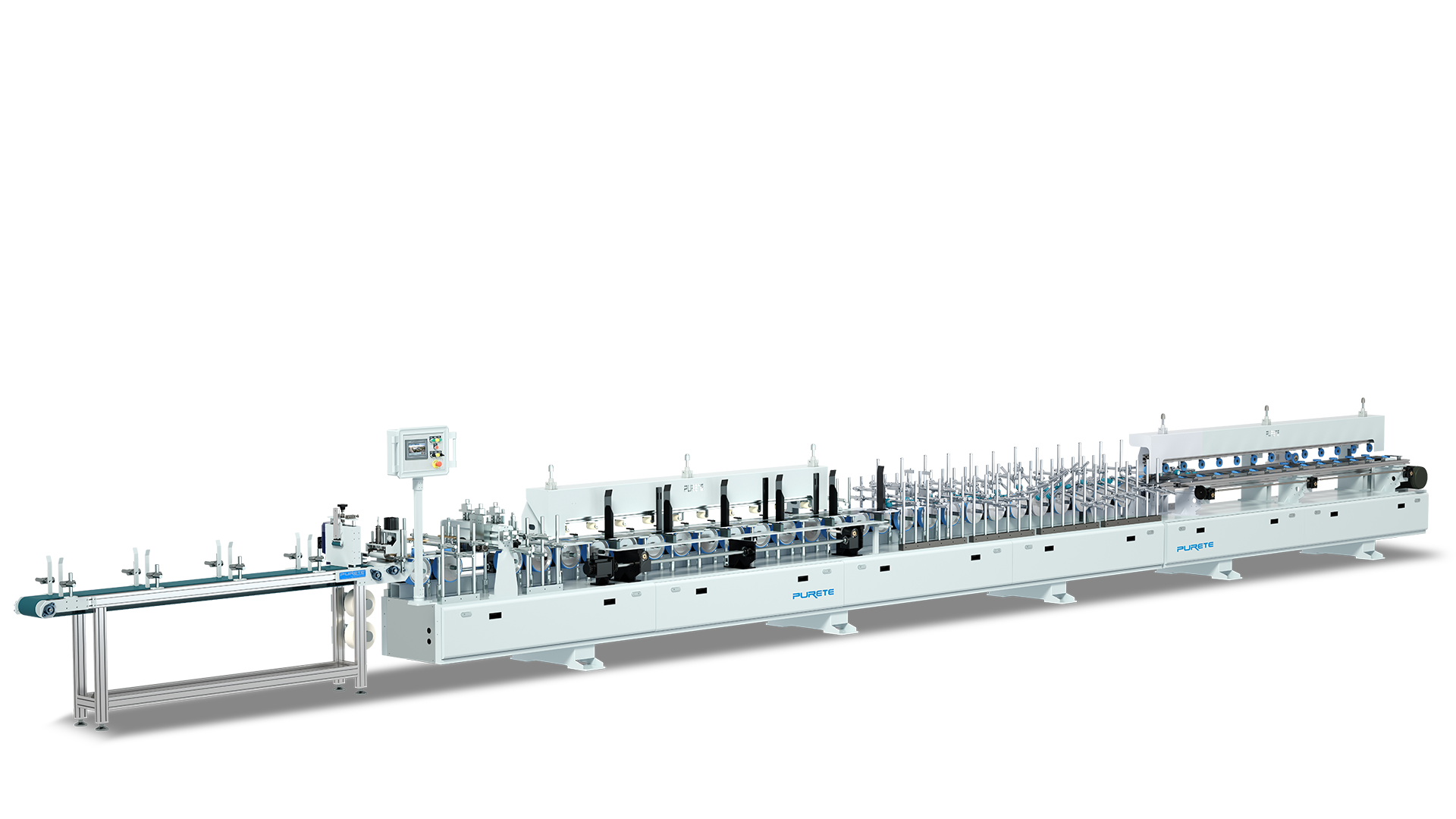

Wrapping Production Lines

Working Principles

A wrapping production line is designed to apply decorative films or foils—such as PVC, PP, PET, or veneer—onto wood or MDF substrates using heat, pressure, and adhesive systems (often PUR hot melt).

The process typically includes:

Profile feeding and alignment

Glue application

Film heating and forming

Wrapping and pressing

Cooling and cutting

This technology is especially effective for three-dimensional and profiled components, where traditional flat coating methods are not suitable.

Ideal for Profiles, Skirting, and Frames

Wrapping lines are widely used in furniture and interior production for components such as:

Decorative mouldings

Skirting boards

Cabinet frames

Door frames

Window and wall profiles

Because the film fully conforms to the profile geometry, wrapping ensures uniform coverage even on edges, grooves, and curved surfaces.

Benefits for Mass and Consistent Finishing

From a B2B manufacturing perspective, wrapping production lines offer several advantages:

High repeatability across large batches

Minimal color and texture variation

Reduced rework and material waste

Continuous, high-speed operation

These benefits make wrapping lines ideal for mass furniture production and OEM suppliers serving standardized product lines.

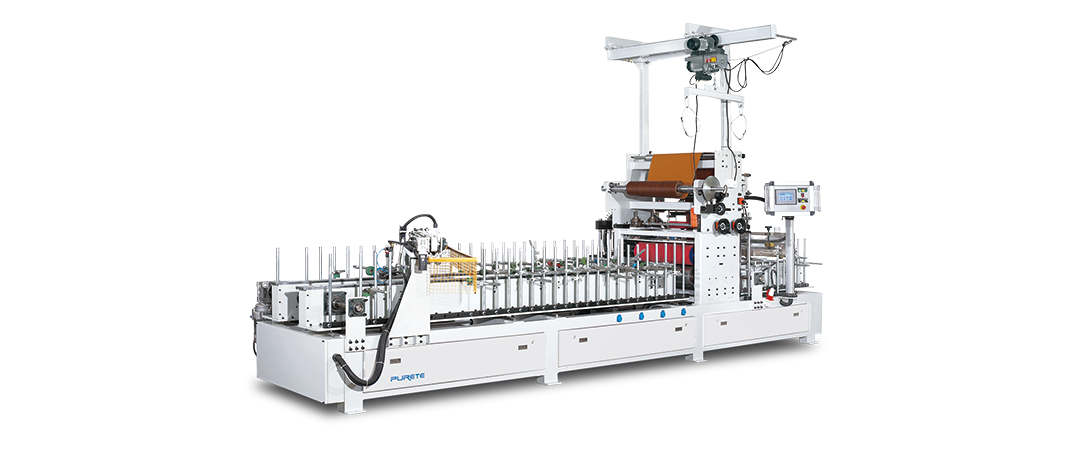

Inert Coating Technology

Inert coating technology represents a more advanced approach to wood surface finishing, particularly for UV-curable coatings.

In this system, coating and curing take place in an oxygen-controlled (inert) environment, typically filled with nitrogen. By eliminating oxygen interference, the coating achieves superior curing performance.

Key Advantages of Inert Coating Systems

Enhanced surface hardness and chemical resistance

Improved gloss control and finish stability

Reduced curing defects such as tackiness

Better performance with UV coatings

Inert coating technology is especially valued in high-end furniture manufacturing, where surface durability and visual quality are critical.

Comparing Wrapping, Roller, and Inert Coating Lines

Different coating technologies serve different manufacturing needs. Understanding their distinctions helps manufacturers select the right investment.

Wrapping Production Lines

Best for profiled and shaped components

Ideal for decorative frames and mouldings

Excellent for continuous, uniform coverage

Roller Coating Lines

Designed for flat panels and boards

High efficiency for large surfaces

Suitable for primers, topcoats, and UV coatings

Inert Coating Lines

Focused on premium surface performance

Ideal for UV coatings requiring precise curing

Common in high-end or export-oriented furniture production

In many modern factories, these technologies are combined into integrated surface finishing systems rather than used independently.

Applications in the Furniture Industry

Decorative Mouldings

Decorative mouldings require consistent surface appearance across long production runs. Wrapping and inert coating technologies ensure stable color, texture, and edge quality.

Cabinet Frames

Cabinet frames benefit from wrapping lines due to their complex profiles and high visual exposure. Durable coatings also improve resistance to moisture and daily wear.

Door Frames and Lines

Door frames demand precise surface finishing to match door panels and wall elements. Wrapping production lines provide seamless coverage and uniform aesthetics.

Wall Panels

Wall panels—both flat and profiled—often use a combination of roller coating and inert coating technologies to achieve premium decorative finishes with long-term durability.

PURETE's Full-Solution Surface Finishing Lines

As a comprehensive industrial solution provider, PURETE offers complete wood surface coating systems that integrate multiple technologies into unified production lines.

Integrated Wrapping and Coating Solutions

PURETE's surface finishing lines are designed to combine:

Wrapping production lines for profiled components

Roller coating systems for flat panels

UV and inert coating modules for enhanced surface performance

This integration allows manufacturers to process diverse product categories within a single, coordinated production environment.

Supporting Flexible Product Portfolios

With modular system design, PURETE surface finishing lines allow manufacturers to adapt to:

Different coating materials

Changing surface design trends

New furniture product lines

This flexibility is especially valuable for manufacturers serving both domestic and export markets.

Conclusion

Advanced wood surface coating solutions have become a cornerstone of modern furniture manufacturing. From wrapping production lines handling complex profiles to inert coating technology delivering premium surface performance, each system plays a vital role in efficient, large-scale production.

By adopting integrated surface finishing lines that combine multiple coating technologies, furniture manufacturers can improve consistency, reduce waste, and meet increasingly demanding market standards. With full-solution capabilities and industrial-grade design, PURETE continues to support manufacturers seeking reliable, future-ready wood surface finishing systems.