7×9-foot longitudinal Vertical short-cycle press laminating production line

October 10, 2025

October 10, 2025 Hits:686second

Hits:686secondOur high-capacity 7×9-foot longitudinal short-cycle press laminating production line is about to ship!

The “sure-win” solution for large-panel veneering is here!

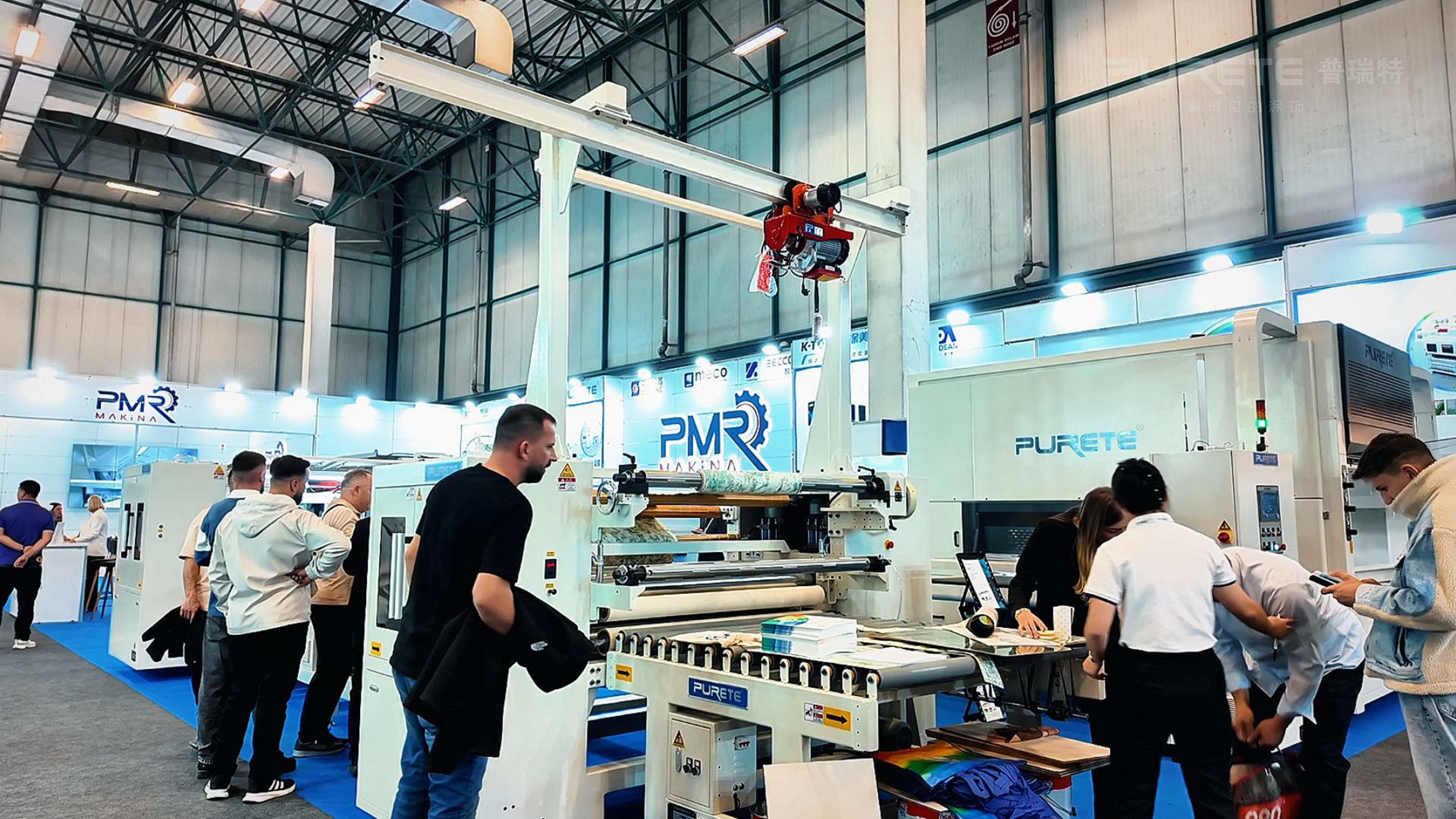

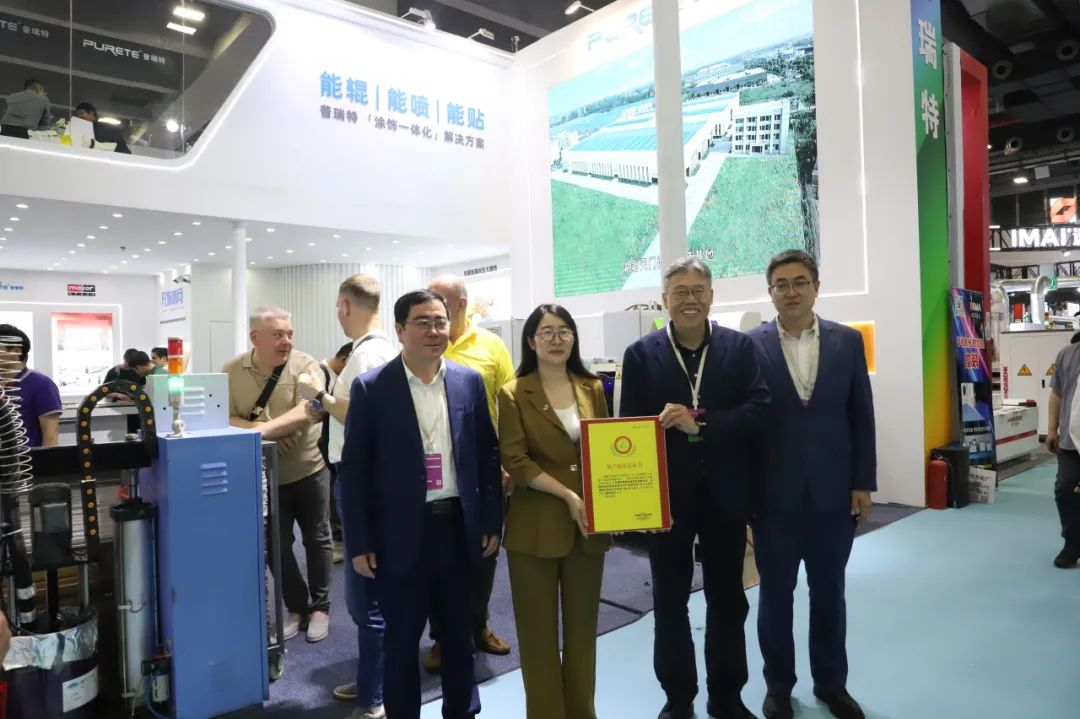

On the afternoon of October 10, 2025, PURETE's Shunde headquarters opened its doors for a live demonstration, showcasing a 4,700-ton 7x9-foot longitudinal short-cycle laminating production line. This innovative solution offers a new approach to laminating for decorative panel manufacturers, inviting numerous upstream and downstream partners to attend and evaluate the facility.

1. Precision and Stability

Our laminating systems deliver superior temperature control, noise reduction, and efficiency—far exceeding industry averages—ensuring high yield rates for premium finishes.

2. Comprehensive Turnkey Solutions

We provide end-to-end support encompassing process engineering, installation, and training to safeguard your finishing operations.

3. Modular and Intelligent Design

Supporting rapid changeovers, remote monitoring, and data traceability, our systems enable flexible manufacturing and digital transformation—delivering a fully equipped digital factory in one step.

Customer Case Studies

PURETE's short-cycle press laminating production lines have been deployed in over 80 installations within a single year, serving more than 20 clients. Below are some on-site examples:

1. JIEUISEN

A single workshop houses over twenty PURETE short-cycle press laminating production lines, arranged in a standardized array layout. Daily production schedules are precisely assigned to specific presses, with orders grouped for management to minimize frequent steel plate changes caused by scattered orders. This setup supports a 60% increase in high-end particleboard surface laminating capacity.

2. LULI

Over a dozen PURETE short-cycle pressing lines have been introduced across multiple bases in Jiangxi, Hunan, Shandong, and other regions. The pressing process employs servo-driven precision positioning and utilizes 3,200-ton heavy-duty presses to achieve deep embossing and high quality. This setup ensures dual guarantees of production capacity and efficiency, reducing labor costs by 40% compared to original equipment. Products are exported to Europe, Southeast Asia, and other regions.

3.HUALIN

Purchased PURETE's short-cycle press laminating production line, rapidly entered the large-scale engineering and decoration project market, and achieved rapid annual revenue growth.

Top Ten Highlights for Comprehensive Enhancement

PURETE's short-cycle press laminating production line offers ten key advantages, delivering superior solutions for decorative panels!

Highlight 1: Fully Automatic Double-Sided Paper Feeding System

Highlight 2: Vertical Board Feed

Highlight 3: Large Tonnage 4,700 tons

Highlight 4: Standard Steel Plate Replacement Mechanism

Highlight 5: Automatic Edge Scraping with No Burrs

Highlight 6: Double-Sided Inspection Mechanism

Highlight 7: Four-Channel Oil Circuit

Highlight 8: Standard-equipped with Rexroth hydraulic valves

Highlight 9: Full range of Siemens and Schneider electrical components

Highlight 10: High-speed synchronized feeding/discharging: German SEW servo system

Conclusion

We understand that equipment quality is judged not only by specifications but by real-world performance; a production line's value lies not just in paper data but in its ability to truly resolve your capacity bottlenecks. Therefore, PURETE cordially invites you to visit our headquarters factory for an in-depth inspection where you can “see, touch, and discuss” firsthand.