Benefits of Automated Production Lines

May 21, 2025

May 21, 2025 Hits:1048second

Hits:1048secondIn today's fast-paced industrial era, automated production lines have become the backbone of advanced manufacturing. As global competition intensifies and customer expectations rise, manufacturers are under constant pressure to deliver high-quality products faster and more cost-effectively. Automation is no longer a futuristic concept—it is a present-day necessity. By integrating robotics, intelligent control systems, and data-driven technologies, automated production lines are revolutionizing how goods are produced, assembled, and delivered. This article explores the definition, roles, and comprehensive benefits of automated production lines, offering insights for manufacturers seeking to enhance their operations and maintain a competitive edge.

What Are Automated Production Lines?

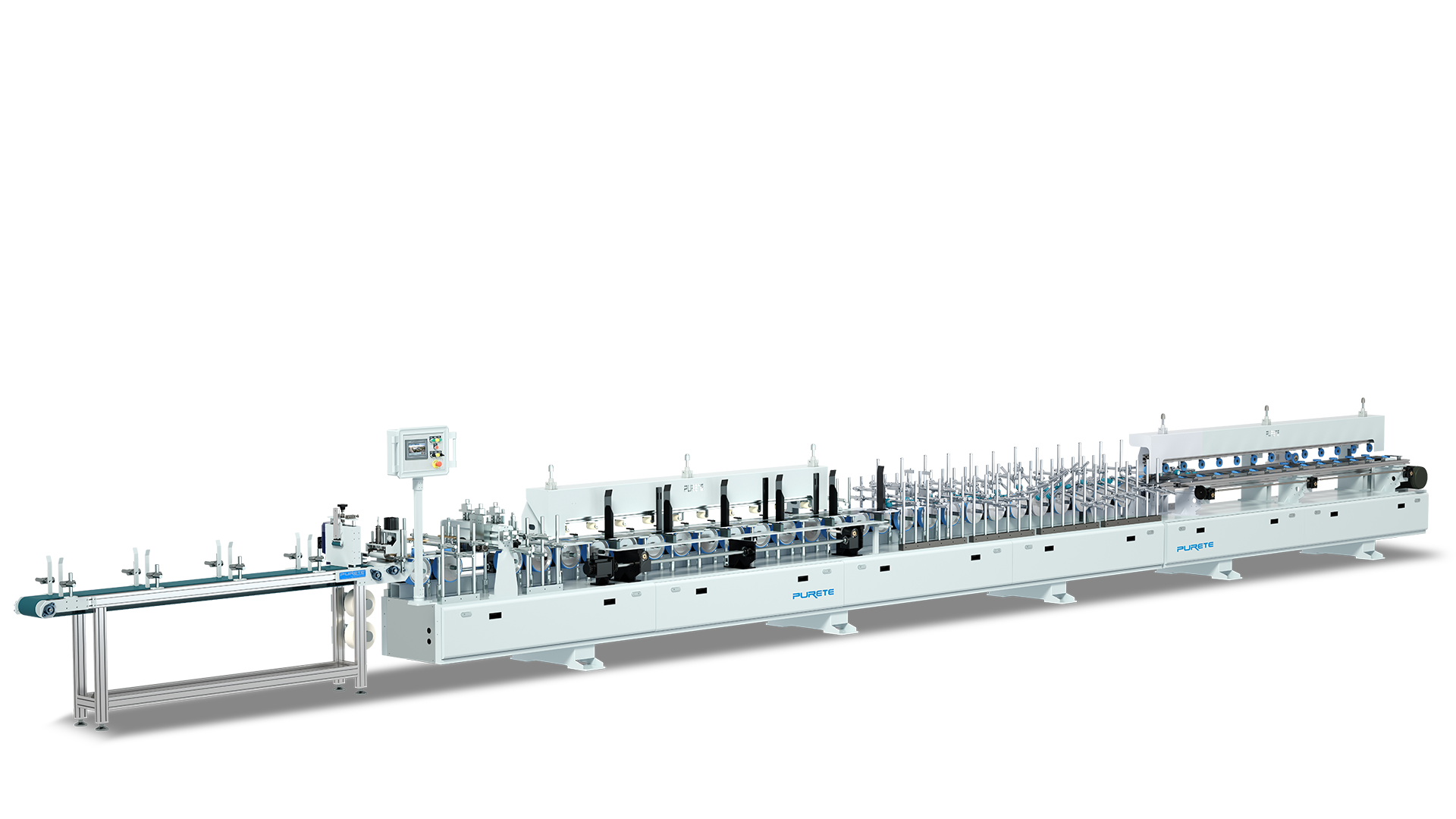

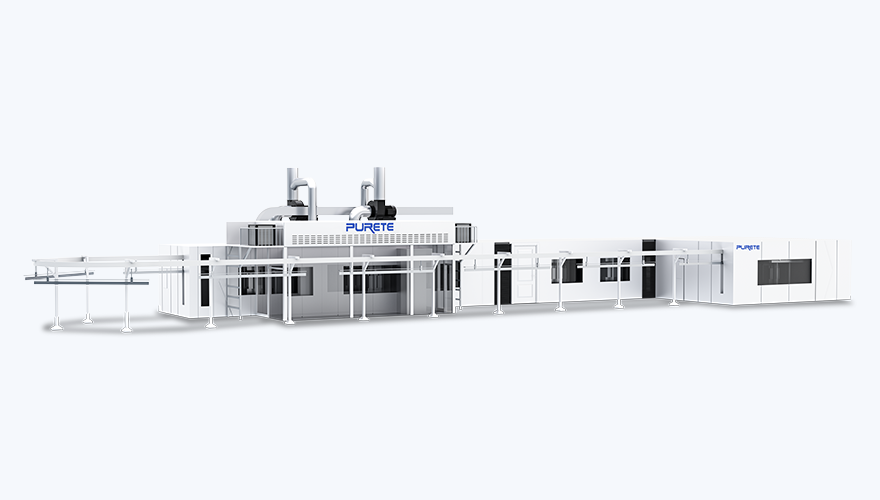

Automated production lines are sophisticated systems where machines, robotics, and control software work in harmony to perform manufacturing processes with minimal human intervention. These lines are meticulously designed to handle tasks that are repetitive, labor-intensive, or hazardous, ensuring that each product is manufactured with precision, speed, and consistency. Unlike traditional manual assembly lines, automated systems can operate around the clock, maintaining strict quality standards and adapting swiftly to changes in production requirements.

Key components of automated production lines include:

Robotic arms and manipulators for assembly, welding, painting, and packaging.

Conveyor systems for efficient material handling and transportation.

Sensors and vision systems for real-time inspection and quality assurance.

Programmable Logic Controllers (PLCs) and industrial computers for process control and data management.

Human-Machine Interfaces (HMIs) for monitoring and supervision.

By leveraging these technologies, automated production lines can achieve levels of efficiency and precision that are unattainable through manual processes.

The Role of Automated Production Lines in Modern Manufacturing

Automated production lines play a pivotal role in shaping the future of manufacturing. Their impact extends across several critical dimensions:

Operational Efficiency: Automation streamlines workflows, reduces manual intervention, and eliminates bottlenecks, resulting in smoother and more predictable operations.

Quality Assurance: Automated inspection systems detect defects in real time, ensuring that only products meeting stringent standards reach the market.

Scalability: Automated lines can be scaled up or down to accommodate fluctuations in demand, providing manufacturers with the agility needed to respond to market dynamics.

Data-Driven Decision-Making: Advanced automation systems collect and analyze production data, enabling continuous improvement and informed decision-making.

Sustainability: Automation optimizes resource usage, reduces waste, and supports environmentally friendly manufacturing practices.

These roles underscore the strategic importance of automated production lines for manufacturers aiming to thrive in an increasingly complex and competitive environment.

Benefits of Automated Production Lines

1. Increased Productivity and Throughput

One of the most compelling advantages of automated production lines is the substantial boost in productivity. Automated systems can operate continuously, 24 hours a day, seven days a week, without the limitations of human fatigue or shift changes. This uninterrupted operation translates into significantly higher output and faster production cycles.

For example, a factory equipped with automated assembly lines can double or even triple its production capacity compared to traditional manual lines. This enables manufacturers to fulfill large orders, respond quickly to market demands, and maintain a steady supply chain. Furthermore, automation minimizes downtime by integrating predictive maintenance and real-time monitoring, ensuring that equipment operates at peak efficiency.

2. Enhanced Consistency and Quality

Consistency and quality are paramount in manufacturing. Automated production lines utilize precision robotics and advanced control systems to ensure that every product is manufactured to exact specifications. Unlike manual processes, which are prone to human error and variability, automation guarantees uniformity across all production batches.

Automated inspection systems, such as machine vision and laser measurement, can detect even the slightest defects or deviations from quality standards. This leads to:

Reduced defect rates: Fewer faulty products reach the market, minimizing returns and warranty claims.

Improved customer satisfaction: Consistent quality builds trust and enhances brand reputation.

Regulatory compliance: Automated systems help manufacturers adhere to industry standards and certifications.

3. Cost Reduction

While the initial investment in automation may be significant, the long-term cost savings are substantial. Automated production lines reduce both direct and indirect costs in several ways:

Labor costs: Automation decreases the reliance on manual labor, allowing companies to operate with leaner teams and allocate human resources to higher-value tasks such as process optimization and quality control.

Material costs: Precise handling and processing minimize material waste, reducing the cost of raw materials and scrap.

Operational costs: Continuous operation and optimized energy consumption lower utility expenses and maintenance costs.

Over time, these savings contribute to a faster return on investment (ROI) and improved profitability.

4. Improved Employee Safety

Manufacturing environments often involve hazardous tasks, such as heavy lifting, exposure to toxic substances, or operating dangerous machinery. Automated production lines mitigate these risks by assigning such tasks to machines, creating a safer workplace for employees.

By reducing the likelihood of workplace accidents and injuries, automation not only protects workers but also lowers costs associated with workers' compensation, insurance, and lost productivity. Employees can focus on supervisory, maintenance, and analytical roles that are less physically demanding and more intellectually stimulating, leading to higher job satisfaction and retention.

5. Flexibility and Adaptability

Modern markets demand agility. Automated production lines are designed for flexibility, allowing manufacturers to quickly adapt to changing product designs, batch sizes, or customer requirements. Through reprogrammable robotics and modular system architectures, production lines can be reconfigured with minimal downtime.

This adaptability is crucial for:

Product customization: Meeting the growing demand for personalized products.

Rapid prototyping: Accelerating the development and launch of new products.

Seasonal adjustments: Scaling production up or down to match market trends.

Manufacturers equipped with flexible automation can stay ahead of competitors and capitalize on emerging opportunities.

6. Better Production Capacity and Efficiency

Automation not only increases the volume of products that can be manufactured but also optimizes resource utilization. Automated systems are designed to maximize throughput while minimizing waste, energy consumption, and floor space requirements.

Key efficiency gains include:

Shorter lead times: Faster production cycles enable quicker order fulfillment.

Higher yield rates: Improved process control reduces scrap and rework.

Sustainable practices: Efficient use of materials and energy supports environmental goals.

By enhancing both capacity and efficiency, automated production lines empower manufacturers to achieve operational excellence and long-term sustainability.

Conclusion

The integration of automated production lines is fundamentally transforming the manufacturing landscape. From increased productivity and consistent quality to cost savings, improved safety, and unmatched flexibility, the benefits of automation are clear and compelling. As technology continues to advance, manufacturers who embrace automation will be better positioned to meet the challenges of the future and seize new growth opportunities.

If you are looking to upgrade your manufacturing processes and unlock the full potential of automation, consider partnering with PURETE. Our cutting-edge automated production solutions are designed to deliver superior performance, reliability, and scalability. Contact PURETE today to discover how we can help you achieve your manufacturing goals and stay ahead in the competitive market.