Top Benefits of Using Roller Coating Machines in Industrial Manufacturing

June 25, 2025

June 25, 2025 Hits:1867second

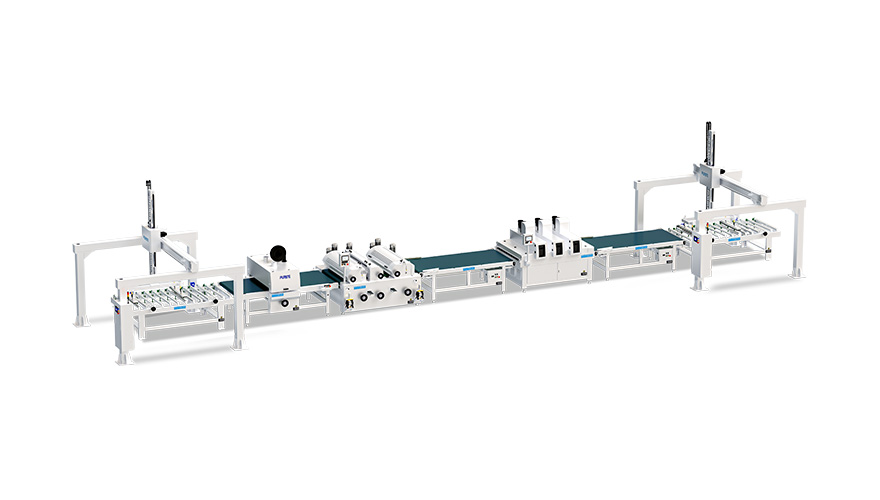

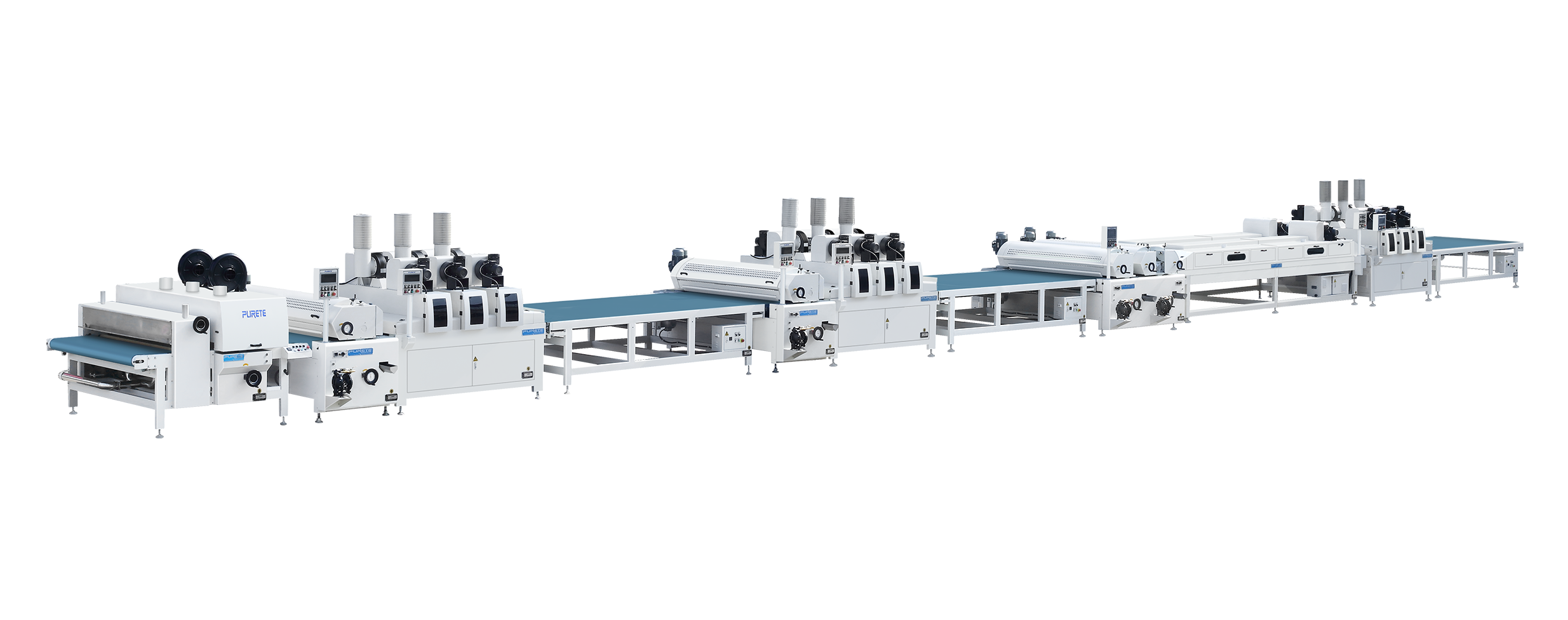

Hits:1867secondIn today's competitive industrial landscape, the roller coating machine has become a cornerstone technology for manufacturers seeking to boost productivity, ensure consistent surface quality, and meet rising demands for eco-friendly production. As global markets evolve, the need for advanced surface coating solutions—capable of handling diverse substrates and custom requirements—has never been greater. PURETE's innovative roller coating equipment delivers exactly this, offering scalable, automated, and sustainable solutions for industries worldwide.

What Is a Roller Coating Machine?

A roller coating machine is a specialized industrial coating system designed to apply paint, lacquer, adhesive, or UV coatings evenly to flat or slightly contoured surfaces. Unlike spray coating or manual brushing, the roller coater uses precision-engineered rollers to achieve a uniform coating thickness, superior adhesion, and a flawless finish. Roller coating technology is essential in sectors such as woodworking, metal fabrication, glass processing, and plastics, where surface uniformity and durability are critical.

Key Benefits of Roller Coating Machines

High Efficiency and Productivity

The adoption of an automatic roller coating machine translates directly into higher throughput and reduced production time. With features like adjustable conveyor speed, programmable controls, and integrated drying systems, manufacturers can achieve continuous, high-speed operation. For example, in the American cabinetry industry, a wood roller coater can process wide panels with remarkable efficiency, while Southeast Asian flooring producers rely on industrial roller coaters for mass production of wood planks. The result is a streamlined workflow, minimized bottlenecks, and the ability to scale output to meet market demands.

Uniform and Precise Coating Application

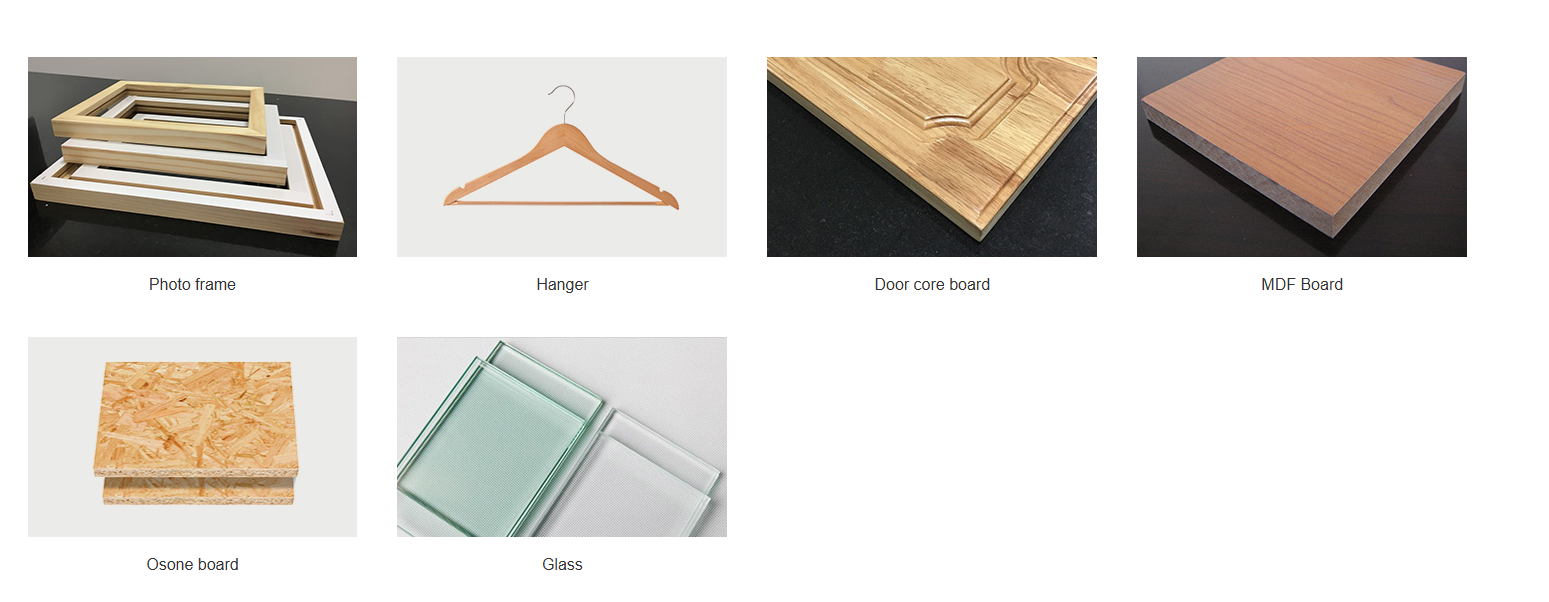

A key advantage of the roller coating machine is its ability to deliver consistent, defect-free finishes. The machine's adjustable pressure and roller speed ensure that each substrate—whether MDF, plywood, metal sheet, or glass panel—receives an even, controlled layer of coating. This is vital for applications like Korean glass panel finishing, where a glass roller coating machine provides high-gloss, scratch-resistant surfaces. The precision of the roller coating process eliminates common issues such as streaking, pooling, or uneven coverage, thus enhancing the final product's appearance and performance.

Material Savings and Reduced Waste

Roller coating equipment is engineered for material efficiency. By applying coatings only where needed and in tightly controlled amounts, these machines reduce overspray and minimize excess material use. This not only lowers raw material costs but also supports sustainability goals by reducing waste. In regions with strict environmental regulations, such as the European Union and North America, the ability to minimize waste and control emissions is a crucial benefit for manufacturers.

Versatility Across Materials and Industries

The versatility of the roller coating machine is unmatched. It can handle a wide range of substrates—including wood, engineered boards, glass, metal, and plastic—making it suitable for a variety of industries. PURETE's custom roller coating machines are available in working widths from 1300mm to 2550mm, allowing for both standard and custom panel sizes. This flexibility is ideal for manufacturers serving multiple markets:

American-style cabinets: Wide-format panel roller coaters deliver uniform finishes on large cabinet doors and panels.

Southeast Asian wood flooring: UV roller coating machines and wood coating equipment provide durable, beautiful finishes for high-volume flooring production.

Korean glass finishing: Glass roller coaters apply decorative and protective coatings to architectural glass, meeting the high standards of Korean interior design.

Enhanced Product Quality and Consistency

Automated roller coating lines reduce the risk of human error and ensure repeatable, high-quality results. Whether producing luxury furniture, commercial flooring, or decorative glass, the industrial roller coater guarantees that every piece meets strict quality standards. This level of consistency is essential for maintaining brand reputation and satisfying customers in both domestic and export markets.

Operational Safety and Environmental Advantages

Modern roller coating machines prioritize both operator safety and environmental responsibility. The use of UV roller coating technology and water-based coatings significantly reduces volatile organic compound (VOC) emissions, making the process safer for workers and more environmentally friendly. Energy-efficient UV curing systems further lower operational costs and carbon footprint, while the precise application reduces hazardous waste and simplifies compliance with environmental regulations.

Cost Efficiency and Long-Term Savings

Investing in a roller coating machine offers substantial long-term savings. Automation reduces labor costs, while material efficiency and minimal maintenance requirements lower the total cost of ownership. For manufacturers in regions facing labor shortages or high wage costs, such as parts of East Asia and Europe, the automatic roller coater is a reliable solution for maintaining profitability and competitiveness.

Applications of Roller Coating Machines in Industry

The roller coating machine is an essential tool across a wide range of industries:

Woodworking and furniture: From cabinets to flooring and decorative panels, wood roller coaters deliver the speed and quality required for both mass production and custom projects.

Metal fabrication: Metal roller coating machines are used for coating sheets, automotive parts, and appliances, ensuring corrosion resistance and aesthetic appeal.

Glass processing: Glass roller coaters apply decorative and protective finishes to glass panels, mirrors, and architectural elements.

Plastics and electronics: Plastic roller coating machines are ideal for coating casings, panels, and consumer goods where surface quality is critical.

Packaging and printing: Paper roller coaters and flexible packaging coating machines apply finishes that enhance durability and visual appeal.

Environmental Friendliness

The roller coating machine is at the forefront of sustainable manufacturing. The use of UV coatings and water-based finishes means fewer harmful emissions and a cleaner production environment. Energy savings from instant UV curing and efficient material usage further reduce the environmental impact. The precise, targeted application process also means less waste, and in many cases, unused coatings can be reclaimed or recycled, supporting a circular economy.

Labor Cost Reduction

The automation provided by the roller coating machine streamlines production and reduces reliance on skilled labor. With intuitive controls and automated features, operators can manage the entire roller coating line with minimal training. This is particularly valuable in regions with rising labor costs or shortages of skilled workers, helping manufacturers maintain efficiency and profitability.

Broad Coverage and Customization

PURETE's roller coating machines are designed for adaptability. With customizable working widths from 1300mm to 2550mm, manufacturers can process a wide variety of panel sizes and shapes. Whether producing wide panels for American cabinets, narrow strips for Southeast Asian flooring, or specialized glass panels for the Korean market, the roller coating system can be tailored to meet specific production requirements.

Conclusion

The roller coating machine is a game-changer in industrial manufacturing, offering unmatched benefits in efficiency, product quality, environmental sustainability, and cost savings. Its ability to deliver uniform, high-quality finishes across diverse materials and industries makes it an essential investment for manufacturers seeking to stay ahead in today's global market. With advanced features such as customizable widths, UV-curable coatings, and intelligent automation, PURETE's industrial roller coating machines empower companies worldwide to achieve superior results while reducing their environmental footprint and operational costs. As demand for sustainable, high-performance surface finishing solutions continues to rise, the roller coating machine will remain at the forefront of industrial innovation.