Choosing a Wrapping Production Line: Key Criteria for Door, Window, and Molding Applications

September 23, 2025

September 23, 2025 Hits:428second

Hits:428secondIn today's competitive door, window, and molding industries, manufacturers face the dual challenge of producing high-quality finishes while maximizing production efficiency. From MDF trims and PVC door frames to aluminum window profiles, the finishing process is a critical step that affects aesthetic appeal, durability, and market competitiveness.

Manual wrapping and conventional coating methods often involve labor-intensive procedures, longer cycle times, and inconsistent results, making it difficult for manufacturers to scale production or maintain uniform quality. Automated wrapping production lines have emerged as a solution, offering precision, speed, and repeatability. Choosing the right system, however, requires a thorough understanding of material compatibility, automation level, line speed, and quality inspection capabilities.

This guide will explore the key criteria for selecting a wrapping production line, emphasizing the advantages of PURETE's advanced systems designed for multi-material applications.

The Growing Need for Wrapping Lines in Door, Window, and Trim Production

Consumer expectations have shifted dramatically in recent years. Homeowners and interior designers increasingly demand high-quality finishes that mimic natural wood or decorative laminates while maintaining durability and scratch resistance.

Traditional wrapping methods struggle to meet these requirements due to:

High labor costs – Manual film application is time-consuming and often requires multiple operators.

Inconsistent coating quality – Human error can result in uneven adhesion, wrinkles, or bubbles.

Long production cycles – Multiple handling steps increase total manufacturing time.

Higher material waste – Improper alignment or over-application leads to scrap.

Automated wrapping production lines address these issues by integrating multiple processes, reducing human intervention, and producing uniform, high-quality surfaces efficiently.

For manufacturers producing interior doors, cabinet doors, window frames, or decorative trims, investing in a modern wrapping line is no longer optional—it's a strategic decision to improve throughput and reduce costs.

Defining a Wrapping Production Line

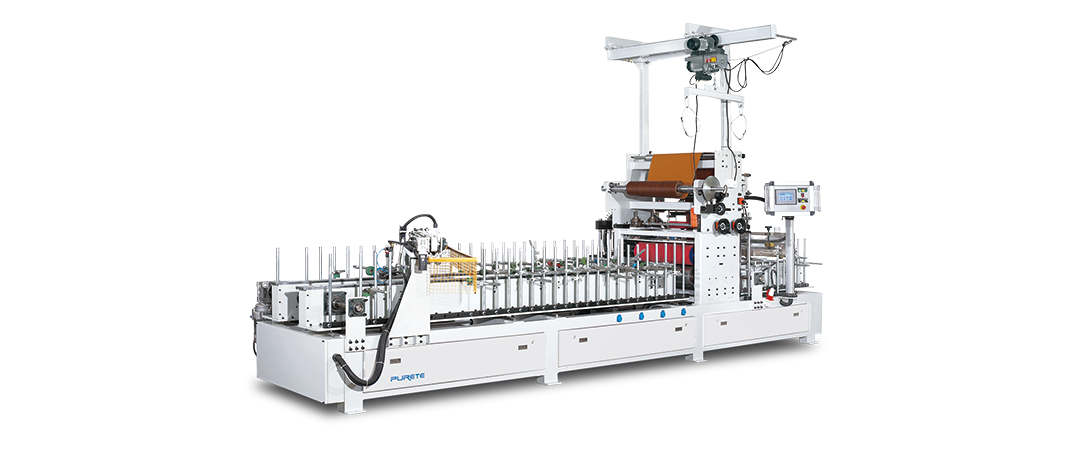

A wrapping production line is an integrated system designed to apply decorative or protective films onto various substrates such as MDF, HDF, PVC, or aluminum profiles. Unlike traditional manual methods, wrapping lines combine precision, automation, and continuous production.

Typical stages of a wrapping production line include:

Substrate feeding and alignment – Ensures panels, trims, or profiles are accurately positioned.

Adhesive or thermal application – Prepares the surface for film bonding using precise amounts of glue or heat.

Wrapping or lamination – Applies the decorative film evenly and consistently.

Curing, pressing, or heat treatment – Secures the film, ensuring durability and adhesion.

Quality inspection and trimming – Detects surface defects, misalignment, and ensures precise edges.

This integrated approach reduces handling errors, speeds up production, and ensures repeatable, high-quality finishes across different materials.

Must-Have Feature: Material Compatibility (Sublayers + Wrapping Films)

One of the most critical considerations when choosing a wrapping line is material compatibility. Modern manufacturing requires handling a variety of substrates and films:

Substrates: MDF, HDF, PVC, aluminum, and composite profiles

Wrapping films: PVC, PET, melamine, decorative laminates, textured or embossed films

A versatile wrapping line must accommodate different thicknesses, adhesive properties, and surface textures without compromising finish quality. This flexibility allows manufacturers to switch between products seamlessly, from MDF door trims to aluminum window profiles, reducing downtime and increasing overall production efficiency.

Additionally, some advanced systems include multi-layer capabilities, enabling manufacturers to apply sublayers, primer films, and top decorative layers in one continuous operation, further enhancing efficiency.

Critical Specs: Automation Level, Line Speed, and Quality Inspection

Selecting a wrapping line involves evaluating three technical specifications that directly affect production efficiency and product quality:

Automation Level – Higher automation reduces labor requirements, minimizes human error, and increases repeatability. Fully automated lines handle feeding, wrapping, pressing, and inspection with minimal operator intervention.

Line Speed – Optimizing speed ensures high throughput without sacrificing quality. Advanced lines can adjust conveyor speed, wrapping pressure, and curing temperature to match substrate and film type.

Quality Inspection Systems – Integrated cameras and sensors detect defects such as bubbles, misalignment, or color variation in real-time. Automated rejection or correction minimizes scrap and maintains consistent product standards.

A well-designed system balances speed, accuracy, and reliability, allowing manufacturers to maximize output while maintaining premium finish quality.

Industry Applications: From MDF Trim to Aluminum Door Frames

Wrapping production lines are versatile, serving multiple sectors in door, window, and trim manufacturing:

Interior and cabinet doors – Achieve scratch-resistant, decorative finishes for furniture-grade surfaces.

Window profiles – Apply protective and aesthetic films to aluminum or PVC frames, improving durability and weather resistance.

Moldings and trims – Maintain uniform coating on complex shapes and long profiles.

Furniture components – Enable high-volume production of consistent laminated panels.

The ability to process diverse materials and sizes makes wrapping lines a critical investment for manufacturers looking to expand product offerings without compromising efficiency.

Why PURETE Wrapping Lines Stand Out: Customization, Reliability, Multi-Material Use

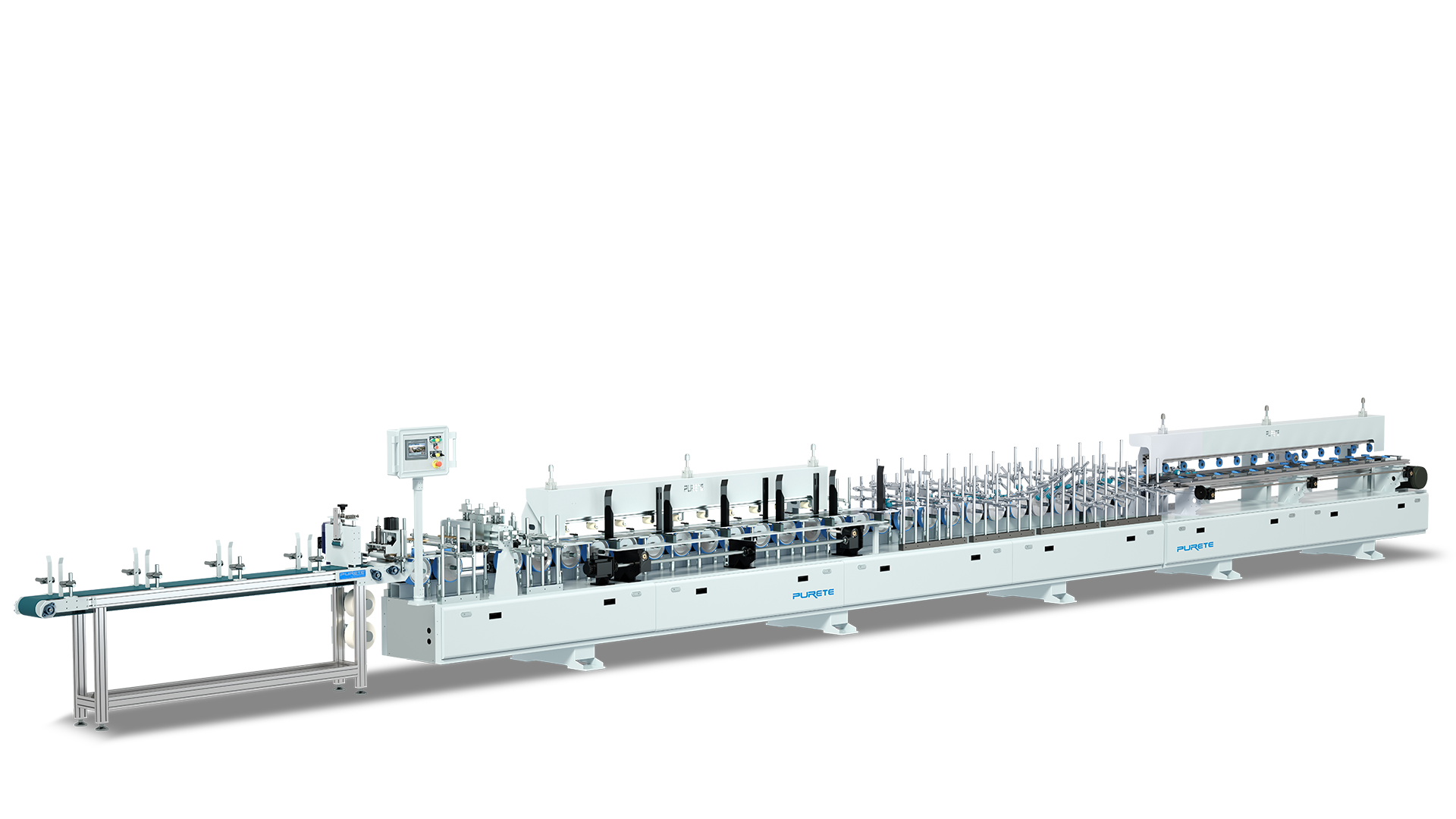

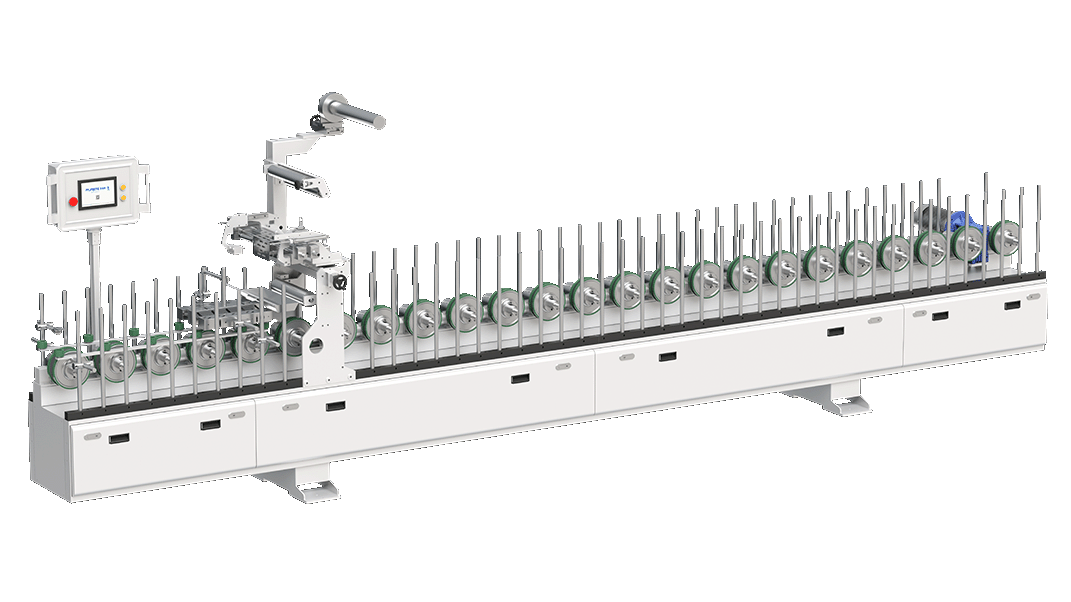

PURETE is a global leader in coating and wrapping technology, known for delivering high-performance, flexible solutions to manufacturers worldwide. PURETE wrapping lines are engineered for efficiency, durability, and adaptability, offering:

Customizable configurations – Tailored to substrate type, film, and production volume.

High reliability – Engineered for continuous operation with minimal downtime.

Multi-material capability – Handles MDF, aluminum, PVC, and composite profiles in the same system.

Advanced quality control – Integrated cameras and sensors ensure defect-free surfaces and consistent finishes.

Energy efficiency – Optimized heat and adhesive systems reduce operating costs and environmental impact.

Manufacturers using PURETE systems experience faster throughput, reduced labor, minimized material waste, and premium finish quality, resulting in a higher ROI and stronger market competitiveness.

Conclusion

Choosing the right wrapping production line is crucial for manufacturers in the door, window, and molding sectors. Critical considerations include:

Compatibility with various substrates and wrapping films

Automation level, line speed, and integrated quality inspection

Flexibility to handle diverse products from MDF trims to aluminum frames

PURETE wrapping production lines provide all these advantages, delivering customized, reliable, and multi-material solutions that streamline production, improve finish quality, and reduce operational costs.

By investing in a modern wrapping line, manufacturers can boost efficiency, reduce waste, and consistently deliver high-quality products that meet the expectations of today's discerning consumers.