How CNC Spray Painting Machines Improve Coating Quality in Modern Furniture Productionay Painting Solutions Conclusion

December 16, 2025

December 16, 2025 Hits:228second

Hits:228secondAs furniture manufacturing continues to evolve toward automation, precision, and sustainable production, surface finishing has become a critical differentiator in product quality and brand competitiveness. Consumers today expect furniture not only to be structurally durable but also visually refined, with flawless coatings, uniform color tones, and long-lasting finishes.

Traditional manual spray painting methods, while flexible, often struggle to meet modern demands for consistency, efficiency, and scalability. Variations in operator skill, high material waste, and inconsistent coating thickness can lead to rework, quality defects, and rising production costs. This is where CNC spray painting machines are transforming the industry.

By combining digital control, automated motion systems, and intelligent spraying technology, CNC spray painting machines enable furniture manufacturers to achieve superior coating quality, higher throughput, and stable mass production. In this article, we explore how CNC spray painting machines improve coating quality in modern furniture production, why manufacturers are rapidly adopting them, and how established solution providers like PURETE support this transition.

What Is a CNC Spray Painting Machine?

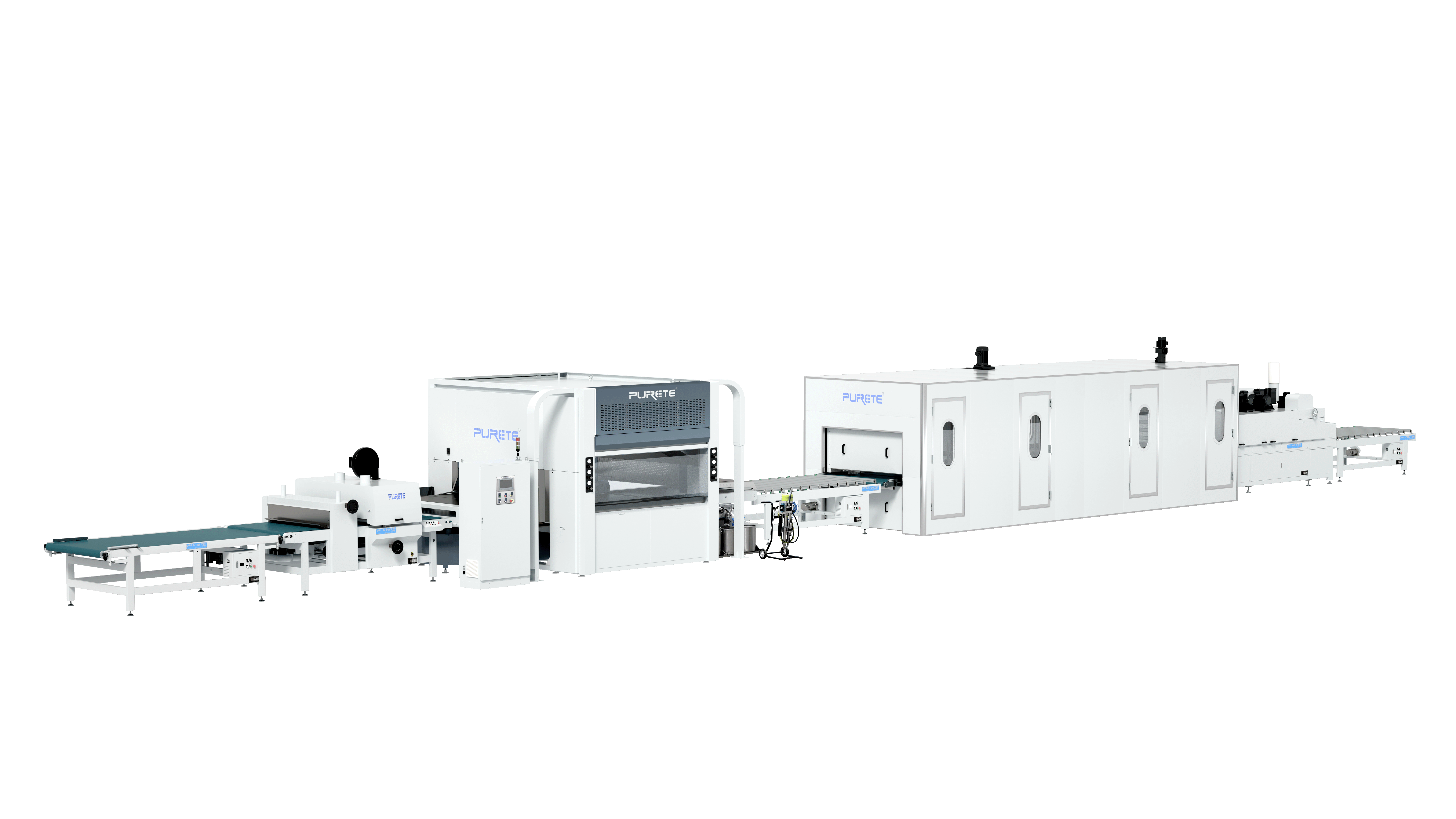

A CNC (Computer Numerical Control) spray painting machine is an automated finishing system designed to apply paint, lacquer, varnish, or other coatings with high precision and repeatability. Unlike manual spraying, CNC spray painting relies on programmed paths, controlled spray parameters, and synchronized movement to ensure uniform coverage across complex furniture components.

Typical CNC spray painting systems include:

Multi-axis robotic arms or gantry systems

Programmable spray guns or atomizers

Precision motion control via CNC software

Automated material supply and recovery systems

Optional integration with conveyors, dryers, or curing ovens

In furniture manufacturing, CNC spray painting machines are widely used for wood, MDF, veneer, and composite surfaces, especially where surface quality and aesthetic consistency are critical.

Why Furniture Manufacturers Are Switching to CNC Spraying

Automation Reduces Labor Dependence

One of the biggest drivers behind the adoption of CNC spray painting machines is the growing challenge of skilled labor shortages. Manual spray painting requires experienced operators to achieve consistent results, and training new workers is time-consuming and costly.

CNC spray painting systems significantly reduce reliance on manual labor by:

Automating repetitive spraying tasks

Maintaining consistent performance across shifts

Reducing human error caused by fatigue or skill variation

For furniture factories facing rising labor costs and workforce instability, CNC spraying offers a reliable long-term solution.

Consistent Coating Thickness

Uniform coating thickness is essential for both appearance and durability. Manual spraying often leads to uneven layers, especially on edges, corners, and complex profiles.

CNC spray painting machines improve coating consistency by:

Maintaining constant spray distance and angle

Precisely controlling paint flow and atomization

Applying programmed overlap patterns

This ensures that every furniture panel, door, or frame receives the same high-quality finish, batch after batch.

Reduced Overspray and Material Waste

Overspray is a major issue in traditional spray booths, leading to wasted paint, increased cleaning, and higher environmental impact. CNC spray painting machines are designed to optimize material usage.

Key benefits include:

Targeted spraying paths that minimize excess paint

Optimized spray parameters for different materials

Integration with paint recovery and filtration systems

As a result, manufacturers can reduce coating consumption, lower operating costs, and improve sustainability performance.

Improvements in Coating Quality

The most visible advantage of CNC spray painting machines lies in coating quality improvement. Automated spraying delivers results that are difficult to achieve consistently through manual methods.

Key quality enhancements include:

Smooth, streak-free surfaces

Uniform color distribution

Reduced defects such as runs, sags, or orange peel

Better edge and corner coverage

By digitally controlling every spraying variable, CNC systems ensure that each component meets strict quality standards—especially important for high-end furniture and export-oriented production.

Efficiency Gains for Production Lines

Faster Throughput

CNC spray painting machines are designed for continuous, high-speed operation. Compared to manual spraying, automated systems can process more parts in less time without sacrificing quality.

This enables:

Shorter production cycles

Faster order fulfillment

Improved responsiveness to market demand

For furniture manufacturers handling tight delivery schedules, this efficiency advantage is critical.

Stable Performance for Large-Volume Orders

Consistency becomes increasingly important as production volumes grow. CNC spray painting machines provide stable, repeatable performance regardless of order size.

Once parameters are programmed:

The same finish can be reproduced indefinitely

Quality remains stable across large batches

Rework and rejection rates are significantly reduced

This stability is especially valuable for OEM furniture production and standardized product lines.

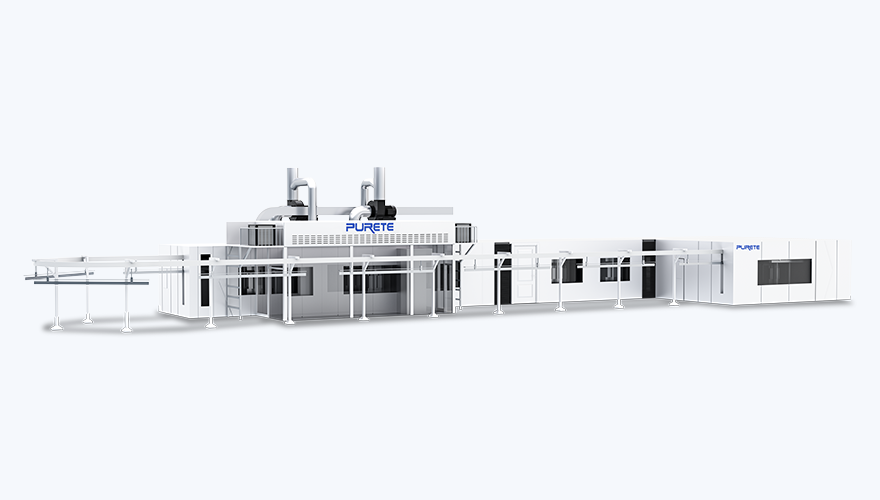

Integration with Conveyors and Curing Systems

Modern CNC spray painting machines are designed to integrate seamlessly with automated production lines. They can be connected to:

Conveyor systems for continuous material flow

Drying tunnels or curing ovens

Sanding and pre-treatment equipment

This creates a fully automated finishing line that maximizes productivity while minimizing manual handling.

Applications in the Furniture Industry

Cabinet Doors

Cabinet doors require smooth surfaces and consistent finishes, especially for kitchens and bathrooms where aesthetics and durability matter. CNC spray painting machines ensure uniform coating across flat and profiled surfaces, improving visual appeal and long-term performance.

Wooden Doors & Frames

Doors and frames often feature complex shapes, edges, and joints. CNC spraying allows precise control of spray angles and coverage, reducing defects and ensuring even finishes on intricate designs.

Wardrobes, Wall Panels, Decorative Boards

Large panels used in wardrobes and wall systems benefit from automated spraying due to their size and surface area. CNC spray painting machines deliver consistent finishes while reducing labor intensity and production time.

High-End MDF Furniture Components

MDF components are widely used in modern furniture but are sensitive to coating quality. CNC spray painting machines help achieve smooth, high-gloss or matte finishes while controlling paint absorption and thickness.

How PURETE Enhances CNC Spray Painting Solutions

At PURETE, we enhance CNC spray painting solutions by focusing on practical performance, process stability, and long-term usability in furniture manufacturing environments.

Precision-Oriented System Design

We design our CNC spray painting machines with precise motion control and optimized spray path programming, ensuring consistent coating thickness and uniform surface finishes across different furniture components.

Stable and Repeatable Coating Performance

PURETE systems are engineered for repeatability, allowing manufacturers to maintain stable coating quality across shifts and large production batches without dependence on operator skill.

Flexible Configuration for Different Furniture Products

Our CNC spray painting solutions are adaptable to various furniture applications, including flat panels, profiled parts, cabinet doors, and MDF components, supporting diverse production requirements.

Seamless Integration into Automated Production Lines

PURETE equipment is designed to integrate smoothly with conveyors, drying systems, and curing ovens, helping manufacturers build efficient, continuous finishing lines.

Compatibility with Common Furniture Coating Materials

We develop our CNC spray painting machines to support commonly used furniture coatings, including water-based and solvent-based paints, enabling manufacturers to meet different finishing and environmental requirements.

Focus on Efficiency and Material Optimization

By optimizing spray control and application logic, PURETE solutions help reduce overspray and improve paint utilization, contributing to lower operating costs and cleaner production environments.

Reliable Support for Long-Term Production

With a focus on durability and system stability, PURETE CNC spray painting machines are built to support long-term, high-volume furniture production with consistent performance.

Conclusion

CNC spray painting machines play an essential role in modern furniture production by improving coating consistency, surface quality, and production efficiency. Through precise control and automation, manufacturers can reduce material waste while maintaining stable finishing results across large production volumes.

At PURETE, we provide CNC spray painting solutions designed to support reliable, efficient, and scalable furniture finishing. By helping manufacturers move from manual spraying to automated coating processes, PURETE enables higher product quality and stronger long-term competitiveness.