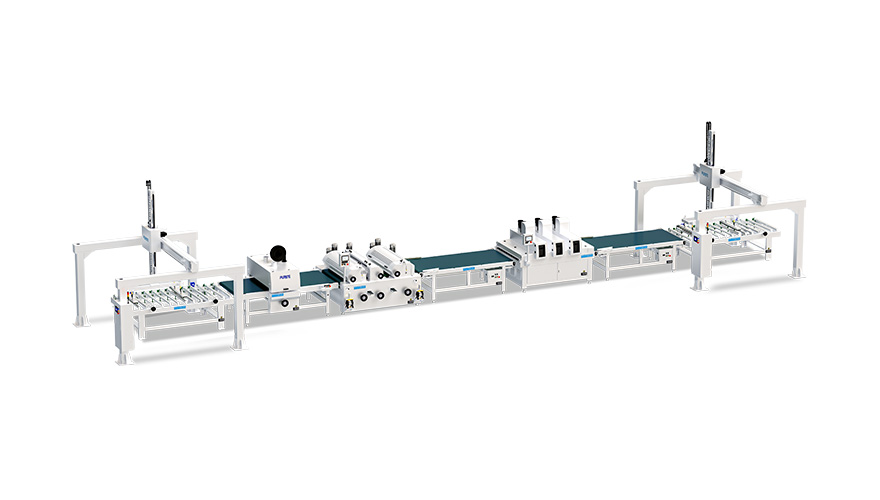

High Gloss Roller Coater: The Ultimate Solution for Your Production Line

May 27, 2025

May 27, 2025 Hits:607second

Hits:607secondIn today's competitive manufacturing environment, achieving a flawless, high-gloss finish is critical for boosting product appeal and maintaining a strong brand reputation. The integration of advanced coating equipment, especially the high gloss roller coater, has transformed production lines by delivering consistent, efficient, and high-quality surface finishes. As manufacturers strive for operational excellence and sustainability, the roller coater emerges as the preferred solution for modern surface finishing challenges.

Why Surface Finishing Matters in Modern Manufacturing

Surface finishing is essential in manufacturing not only for enhancing the appearance of products but also for improving their performance and longevity. A superior finish provides protection against environmental factors, increases resistance to scratches, and elevates the perceived value of the product. Industries such as furniture, flooring, automotive, and electronics rely heavily on advanced surface finishing technologies to meet market expectations and regulatory standards. The demand for uniform, high-gloss finishes has never been higher, making the choice of coating technology—such as the roller coater—crucial for business success.

What Is a High Gloss Roller Coater?

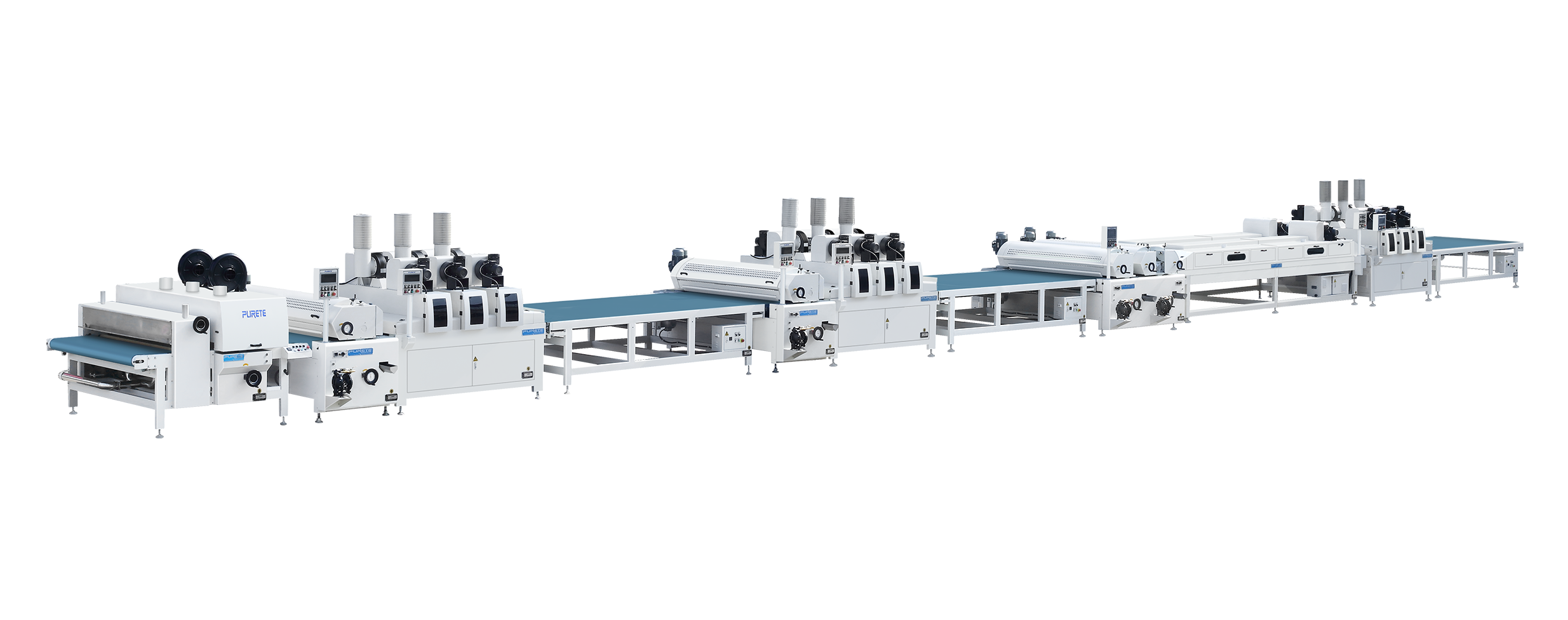

A high gloss roller coater is an industrial coating machine designed to apply a smooth, glossy layer of finish to flat substrates like wood panels, MDF, plastic sheets, and metal surfaces. The roller coater operates by passing materials through a system of feed rollers, application rollers, and doctor rollers, which together ensure an even distribution of coating material—such as UV-curable lacquer, water-based varnish, or solvent-based paint. The process is completed by curing or drying units, including UV lamps or hot air systems, that solidify the finish and produce a durable, mirror-like gloss. This precision engineering allows the roller coater to deliver reliable, repeatable results across various production volumes and substrate types.

Key Advantages of High Gloss Roller Coaters

High gloss roller coaters offer several compelling benefits for manufacturers:

Exceptional Coating Uniformity: Achieve streak-free, bubble-free, and highly consistent finishes.

High Production Throughput: Engineered for continuous operation, roller coaters handle large-scale production with minimal downtime.

Material Efficiency: Advanced controls reduce coating waste, optimize material usage, and lower costs.

Versatility: Suitable for a wide range of coating materials and substrates, roller coaters adapt easily to diverse production needs.

User-Friendly Operation: Modern roller coaters feature intuitive interfaces and modular components for easy maintenance and quick changeovers.

Consistent Quality: Automated settings and sensor feedback guarantee uniform results, regardless of operator or shift.

These advantages make the roller coater an indispensable asset for manufacturers looking to improve quality, reduce costs, and enhance production flexibility.

Applications of High Gloss Roller Coaters in Production Lines

The roller coater's adaptability enables its use in multiple industries and applications:

Furniture Manufacturing: Delivers high-gloss finishes to tables, cabinets, and decorative panels.

Flooring Production: Applies durable, glossy coatings to laminate and engineered wood flooring.

Interior Design Elements: Enhances the appearance and durability of doors, wall panels, and moldings.

Electronics: Provides protective and aesthetic coatings for device housings and display panels.

Automotive Components: Finishes dashboards, trim pieces, and interior panels with a premium gloss.

By streamlining the finishing process and ensuring consistent quality, roller coaters help manufacturers meet the exacting standards of global markets.

Innovations in Roller Coater Technology

Recent advancements in roller coater technology have introduced features such as automated thickness control, energy-efficient curing systems, and enhanced roller materials. These innovations extend machine lifespan, improve coating quality, and help manufacturers reduce operational costs while maintaining high standards of finish. The integration of digital controls and real-time monitoring further optimizes the roller coating process, ensuring maximum efficiency and minimal waste.

Environmental Benefits of Using Roller Coaters

Roller coaters support sustainable manufacturing by minimizing coating waste and enabling the use of eco-friendly materials like water-based varnishes. Their precision application reduces volatile organic compound (VOC) emissions, helps companies comply with environmental regulations, and promotes greener production practices. This makes the roller coater a smart choice for manufacturers committed to environmental stewardship.

Troubleshooting Common Issues with Roller Coaters

Despite their many advantages, roller coaters may occasionally face issues such as roller wear, coating inconsistencies, or curing problems. Regular maintenance, timely replacement of worn parts, and proper calibration are essential to ensure consistent performance and prolong equipment life. Training operators to recognize and address these issues can significantly reduce downtime and improve productivity.

How to Choose the Right Roller Coater for Your Needs

Selecting the right high gloss roller coater involves evaluating several factors:

Substrate Type and Size: Ensure compatibility with the materials and dimensions you process most frequently.

Coating Material: Confirm the roller coater supports your preferred finishes, such as UV-curable, water-based, or solvent-based coatings.

Production Volume: Choose a model that matches your throughput requirements without sacrificing quality.

Automation Features: Look for advanced controls, recipe management, and integration capabilities.

Maintenance and Support: Select a supplier offering robust after-sales service and technical support.

Budget and ROI: Balance initial investment with long-term savings in material usage, labor, and defect reduction.

Consulting with industry experts and reputable equipment suppliers can help you identify the best roller coater solution for your unique production goals.

Conclusion

As the demand for flawless, high-gloss finishes continues to rise, investing in a reliable high gloss roller coater is a strategic move for any forward-thinking manufacturer. With its unmatched efficiency, versatility, and quality control, the roller coater stands as the ultimate solution for modern production lines. If you are seeking a trusted partner for high-performance roller coating solutions, consider PURETE. Contact us today to discover how we can support your production goals.