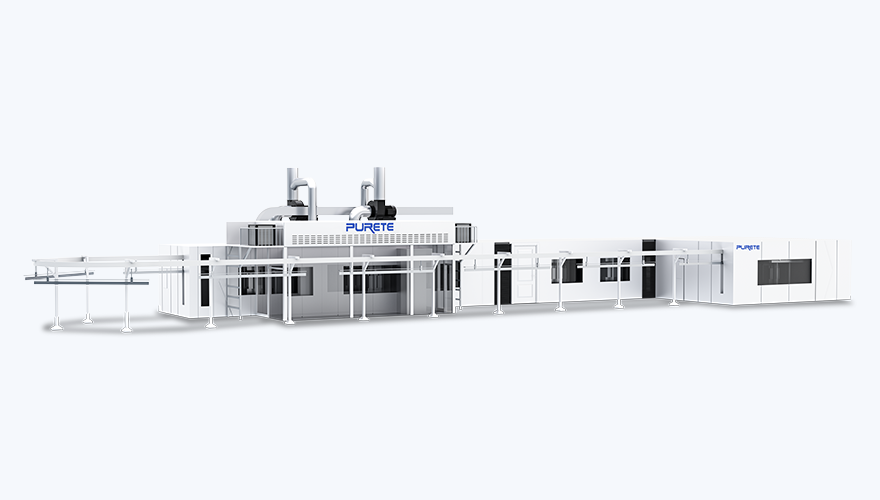

Automatic Spray Painting Machine System for Industrial Applications

November 25, 2024

November 25, 2024 Hits:2778second

Hits:2778secondAutomatic spray painting machine systems have become essential in modern industrial processes, offering precision, efficiency, and cost savings. These systems automate the painting process, ensuring consistent quality while reducing labor costs. In this guide, we explore key features, applications, selection tips, and future trends for industrial automatic spray painting systems.

What is an Automatic Spray Painting Machine System?

An automatic spray painting system is a highly engineered solution designed to automate the application of paint or coatings on various surfaces. These systems improve productivity, reduce errors, and maintain consistent finishes across products.

Key Components

Robotic Arms or Spray Machines: Ensure precise and repeatable coating application.

Conveyor Systems: Move products efficiently through the painting line.

Control Units: Allow programming of spray patterns, speed, and coating types.

Spray Nozzles: Deliver coatings evenly, reducing material waste.

Types of Coatings

These systems can handle water-based, solvent-based, or powder coatings, depending on industry requirements. Selecting the correct coating type ensures durability and performance of the finished product.

Key Features of Automatic Spray Painting Systems

High Precision

Automated control ensures uniform coating thickness, minimizing material waste and improving product quality.

Customizability

Advanced software enables operators to program different spray patterns, speeds, and coating types, adapting the system for multiple applications.

Speed and Efficiency

Automation reduces production time significantly, while maintaining consistent finishes across all units.

Eco-Friendly Options

Many systems are designed to minimize overspray and VOC emissions, supporting environmental sustainability.

Adaptability

These systems are suitable for metals, plastics, wood, and glass, providing versatility across industries.

Applications in Industrial Settings

Automotive Industry

Painting car bodies, bumpers, and components with high precision.

Applying protective coatings such as anti-corrosion layers.

Consumer Electronics

Coating smartphone, laptop, and appliance casings for durability and aesthetics.

Furniture Manufacturing

Uniform finishes on wooden and metal furniture, enhancing visual appeal.

Aerospace Industry

Coating aircraft components for corrosion resistance and improved aerodynamics.

Metalworking and Construction

Applying protective layers on machinery parts, pipelines, and structural components.

Glass and Ceramics

Decorative and protective coatings for glassware and ceramic products.

Advantages of Automatic Spray Painting Systems

Enhanced Quality Control

Automation minimizes human error and ensures consistent surface finishes.

Increased Productivity

Continuous operation accelerates production cycles.

Cost Efficiency

Reduces labor costs and material waste, improving ROI.

Improved Safety

Limits human exposure to toxic fumes and hazardous environments.

Environmentally Friendly

Efficient material usage lowers environmental impact and supports sustainability initiatives.

How to Choose the Right System

When selecting an automatic spray painting system, consider the following factors:

Material Compatibility

Ensure the system supports the paints and surfaces used in your industry.

Automation Level

Decide between semi-automatic and fully automatic systems based on production volume and complexity.

Customizability

Select systems that allow programming for various spray patterns and product types.

Maintenance Requirements

Opt for systems with easy-to-maintain components to minimize downtime.

Environmental Compliance

Choose systems that reduce VOC emissions and material waste, meeting environmental regulations.

Future Trends in Automatic Spray Painting Systems

Integration with Industry 4.0

Smart systems with IoT and AI capabilities enable real-time monitoring, predictive maintenance, and performance analytics.

Eco-Friendly Innovations

Increased use of water-based coatings and sustainable technologies to reduce environmental impact.

Advanced Robotics

Robotic arms are becoming capable of intricate and complex painting tasks, improving precision and flexibility.

Compact and Modular Designs

Space-saving systems can be easily integrated into existing production lines, offering scalability and efficiency.

Conclusion

Automatic spray painting machine systems are transforming industrial production by delivering consistent quality, reducing costs, and increasing efficiency. Businesses investing in reliable and innovative spray painting solutions gain a competitive advantage across industries like automotive, electronics, aerospace, and furniture manufacturing.

Whether upgrading existing lines or setting up new production facilities, these systems offer scalable, eco-friendly, and cost-effective solutions for modern industrial coating needs.