How Automatic Spray Painting Machines Revolutionize Wood Finishing

May 23, 2025

May 23, 2025 Hits:1128second

Hits:1128secondWood finishing is a crucial process in the furniture manufacturing and cabinet production industries, directly influencing product quality, durability, and visual appeal. Traditional wood finishing methods, often relying on manual labor, present significant challenges such as inconsistent results, high labor costs, and safety risks. The rise of automatic spray painting machines has revolutionized wood finishing, offering solutions that address these issues and set new benchmarks for efficiency, quality, and sustainability.

Overview of Traditional Wood Finishing Challenges

Manual wood finishing is labor-intensive and highly dependent on operator skill. Variations in technique, fatigue, and environmental conditions often lead to uneven coatings, material waste, and increased production costs. In addition, manual processes expose workers to hazardous chemicals and make it difficult for manufacturers to comply with strict environmental standards. This is particularly problematic in the production of door panels, cabinet doors, drawers, bed boards, children's furniture, and chairs, where quality and consistency are paramount.

1. Enhanced Consistency and Quality

Automatic spray painting machines deliver unparalleled precision and uniformity in wood finishing. With advanced robotic arms and programmable controls, these machines ensure an even application of coatings, eliminating streaks, drips, and thickness variations. This level of consistency is essential for complex workpieces such as cabinet doors and bed boards.

One of the significant advantages is the ability to handle a wide range of coatings, including water-based UV paint, PU paint, imitation marble paint, and stone paint. This versatility allows manufacturers to meet diverse customer requirements and achieve a professional-grade finish that enhances the value of their products.

2. Increased Productivity and Efficiency

Automation dramatically boosts productivity and efficiency in wood finishing operations. Automatic spray painting machines can process large volumes of workpieces with minimal downtime, making them ideal for mass production environments such as furniture factories and cabinet manufacturers. For example, a fully automated spray painting line can achieve daily outputs of 800 to 1,500 square meters, operating at speeds of 3 to 6 meters per minute. Some systems can coat all sides of a door in just 2–2.5 minutes, supporting up to 24 doors per hour.

Features like programmable spray patterns, automated loading and unloading, and integrated drying ovens streamline operations, reduce bottlenecks, and enable continuous production.

3. Cost Savings and Resource Optimization

Automatic spray painting machines deliver significant cost savings by reducing labor requirements and optimizing material usage. Controlled spray patterns and precise application minimize overspray and paint wastage, resulting in a 30–50% reduction in material consumption compared to manual methods. Automated cleaning and paint reclaim systems further enhance resource efficiency by recycling unused paint.

Reduced reliance on skilled manual painters not only lowers operational expenses but also mitigates risks associated with labor shortages. The result is a faster return on investment and improved profitability for wood finishing businesses.

4. Flexibility and Adaptability

Modern automatic spray painting machines are highly adaptable, capable of handling a wide variety of workpiece shapes, sizes, and surface complexities. With programmable settings and adjustable spray parameters, manufacturers can easily switch between different product lines—such as flat doors, cabinet panels, bed boards, and children's furniture—without extensive retooling.

These machines support various coating types, including water-based UV, PU, imitation marble, and stone paints, ensuring compatibility with changing market trends and customer demands. The flexibility to process both small custom batches and large production runs makes automation a valuable asset for furniture manufacturers and cabinet suppliers.

5. Improved Worker Safety and Environmental Compliance

Automating the spray painting process significantly reduces worker exposure to hazardous chemicals and volatile organic compounds (VOCs). Modern systems are equipped with efficient filtration and exhaust systems that capture overspray and minimize emissions, helping facilities comply with stringent environmental regulations.

By removing operators from direct contact with toxic fumes and flammable materials, these machines create a safer workplace and reduce the risk of occupational illnesses and accidents. The reduction in material waste and VOC emissions also supports sustainability goals and enhances the manufacturer's environmental reputation.

6. Space Optimization and Facility Benefits

Automatic spray painting machines are designed with compact footprints and modular configurations, making them easy to integrate into existing production lines or new facilities. Vertical drying ovens, multi-layer conveyors, and integrated loading/unloading systems maximize space utilization and streamline workflow. Flexible mounting options—such as floor, wall, or ceiling installations—enable manufacturers to customize their setup based on available space and production needs.

This adaptability is especially beneficial for businesses with limited factory space or those seeking to expand capacity without major facility renovations.

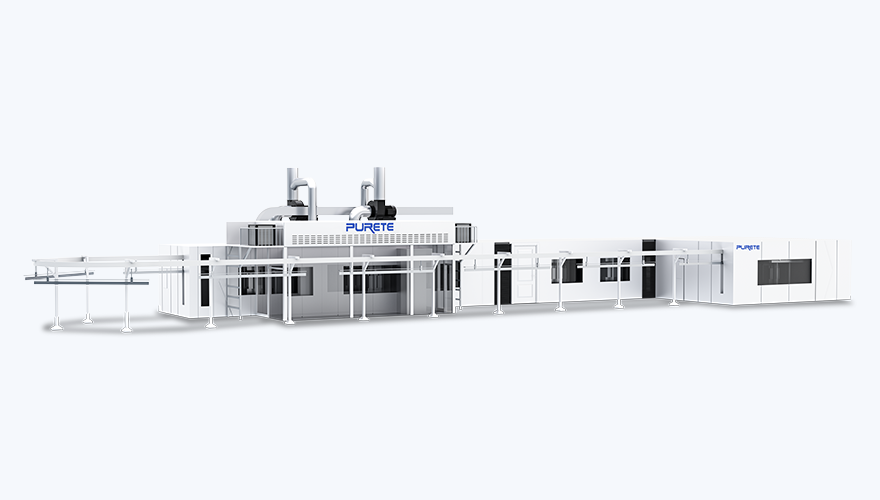

PURETE: A Leading Automatic Spray Painting Machine Supplier

PURETE is a top-tier automatic spray painting machine supplier and wood finishing equipment manufacturer. As a trusted furniture finishing machine supplier and cabinet painting machine manufacturer, we offer a comprehensive range of solutions, including reciprocating spray lines, vertical drying ovens, and multi-material finishing systems.

PURETE's machines are engineered for versatility, supporting a variety of coatings such as water-based UV, PU, imitation marble, and stone paints. They are suitable for complex workpieces like door panels, cabinet doors, drawers, bed boards, and children's furniture. With exports to 81 countries, PURETE has established a reputation for quality, innovation, and reliable technical support.

Conclusion

Automatic spray painting machines have transformed the wood finishing industry by delivering unmatched consistency, efficiency, and cost savings. They enhance product quality, boost productivity, reduce material waste, and improve worker safety and environmental compliance. With advanced features and flexible configurations, these systems empower manufacturers to meet the demands of modern markets—whether producing doors, cabinets, bed boards, or children's furniture, and applying a diverse array of coatings from UV to PU and imitation stone.

As a leading automatic spray painting machine supplier, PURETE exemplifies the transformative power of automated finishing technology, helping businesses achieve superior results and sustainable growth in an increasingly competitive industry.