How to Choose the Right Finishing Line for Your Board Production?

July 18, 2025

July 18, 2025 Hits:649second

Hits:649secondIn today's highly competitive wood processing industry, selecting the appropriate finishing line is crucial to enhancing the quality, durability, and aesthetics of your board products. Whether you're manufacturing MDF, particle board, plywood, or other engineered wood panels, the right finishing solution can significantly improve operational efficiency, surface uniformity, and end-product performance.

This guide will walk you through the key considerations when choosing a finishing line for your board production, including types of technologies available, production goals, and surface requirements. We will also introduce why PURETE, a leading name in the coating equipment industry, is a trusted partner for complete finishing solutions.

Assess Your Board Type and Production Needs

Before selecting a finishing line, it's essential to start with a clear understanding of your board type and production objectives.

Board Material: The characteristics of MDF, HDF, chipboard, plywood, and OSB vary significantly in density, porosity, and surface absorption. These factors directly affect the coating application and drying process.

Production Volume: High-volume manufacturers may prioritize speed and automation, while small to medium-sized facilities might focus on flexibility and cost-efficiency.

End-Use Requirements: Are the boards intended for indoor furniture, kitchen cabinets, or exterior use? Surface hardness, chemical resistance, and UV stability will impact the choice of finishing system.

By analyzing these parameters, manufacturers can better align finishing technologies with their performance requirements and budget constraints.

Understand the Finishing Line Technologies

Finishing lines are not one-size-fits-all. There are several coating technologies available, each suited to different production scales, board types, and finish expectations.

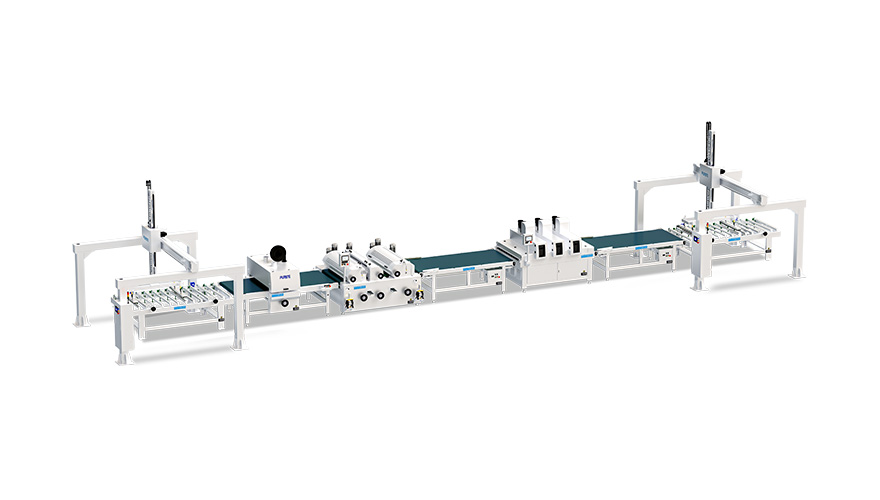

Roller Coating Production Lines

Roller coaters are ideal for flat surface applications and high-throughput operations. This method involves applying a uniform layer of coating using precision rollers.

Advantages:

High-speed and continuous processing

Uniform coating thickness

Low material waste

Best for UV coatings and solvent-based finishes

Applications:

UV lacquer finishing on MDF or melamine boards

Base and top coating for furniture panels

PURETE offers advanced roller coating lines with high automation levels and precision control, ideal for manufacturers aiming for consistency and scalability.

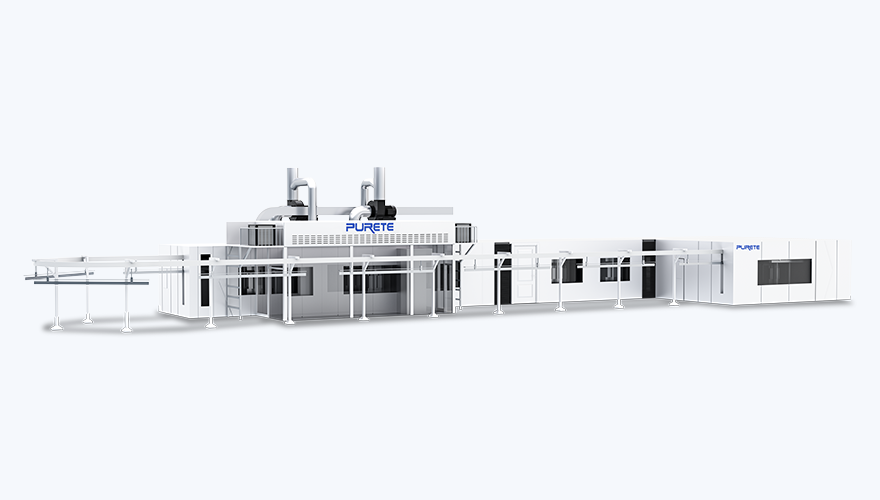

Curtain Coating Production Lines

Curtain coaters apply liquid coating through a curtain of paint falling onto the board as it moves underneath on a conveyor.

Advantages:

Extremely smooth finish with excellent flow-out

Ideal for thick or high-gloss coatings

Suitable for complex topcoat requirements

Applications:

High-gloss UV finishes

Water-based top coatings

Fire-retardant applications

This method is widely used where optical clarity and premium aesthetics are required. PURETE's curtain coating systems are designed with minimal maintenance needs and ensure even distribution across various board sizes.

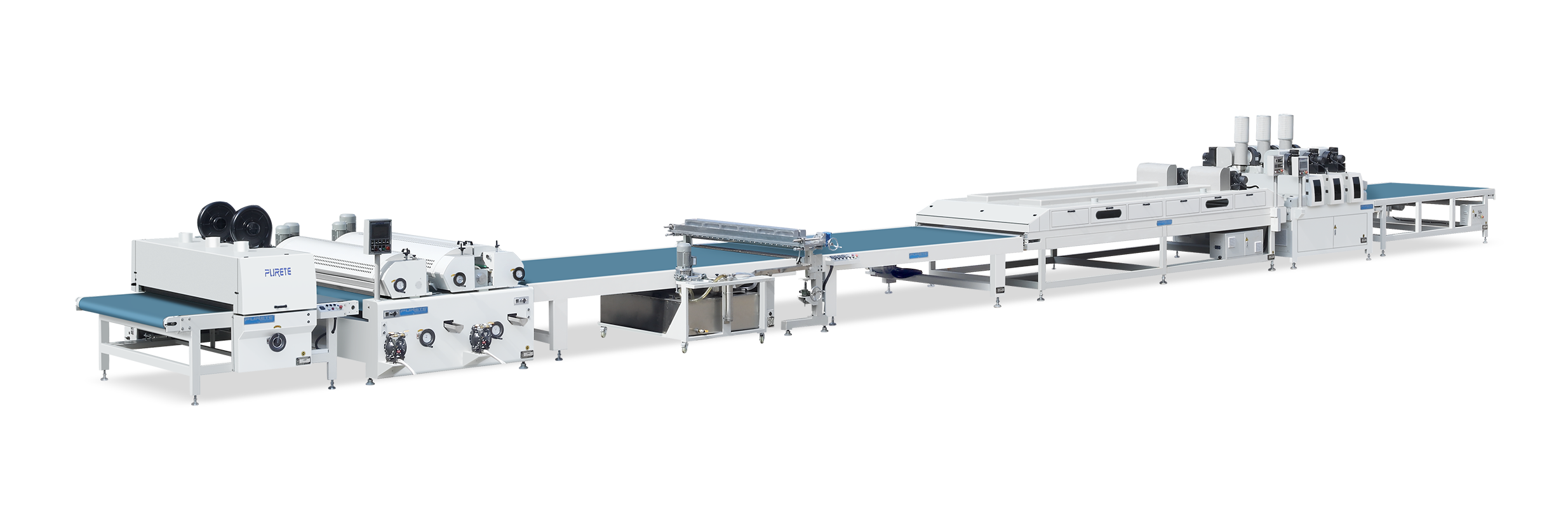

Spraying Painting Production Lines

Spraying systems use automated or robotic spray guns to apply paint or lacquer in fine particles, ensuring good surface coverage, especially on profiled or 3D surfaces.

Advantages:

Versatile for flat and shaped panels

Compatible with solvent, water-based, and UV coatings

Suitable for batch production with varied colors

Applications:

MDF panels with grooves or raised designs

Decorative furniture components

Custom color applications

PURETE's intelligent spray coating lines are engineered with efficient paint recovery systems and precise control for reduced overspray and environmental impact.

How to Choose the Right Coating Finish?

Once you've identified the appropriate finishing technology, the next step is selecting the coating system that matches your product's functional and aesthetic needs.

Key Considerations:

Gloss Level: Choose between matte, satin, semi-gloss, or high-gloss depending on the target market.

Chemical & Scratch Resistance: For kitchen, bathroom, and commercial furniture, durability is key.

Environmental Compliance: Opt for low-VOC and formaldehyde-free coatings to meet international safety standards.

Color Consistency: Important for premium product lines and branded furniture collections.

Some manufacturers may also consider UV LED curing systems to reduce energy costs while improving throughput.

PURETE works closely with chemical partners and coating suppliers to ensure total compatibility between equipment and finishing materials. This integrated approach helps clients achieve optimal results with minimal trial and error.

Why PURETE is a Trusted Partner for Finishing Solutions

With decades of experience in surface coating equipment, we at PURETE have built a strong reputation for delivering turnkey finishing line solutions to panel manufacturers around the world.

What Sets PURETE Apart?

Innovative Engineering: From single machines to fully integrated production lines, our R&D team continuously develops high-efficiency, energy-saving systems tailored to evolving market demands.

Customization Capability: Every plant layout, production goal, and budget is different. That's why we offer flexible configurations to meet your exact requirements and ensure optimal workflow.

After-Sales Support: With a global network of technicians and advanced online diagnostics tools, we provide reliable installation, operator training, and long-term service support, no matter where you are.

Sustainable Focus: All of our equipment is designed with environmental standards in mind—helping you reduce emissions, minimize material waste, and still maintain top-quality finishes.

Global Recognition: As a well-known international brand, we've delivered finishing lines to customers across Europe, Asia, and North America for a wide range of applications—from furniture panels to flooring and decorative boards.

When you choose PURETE, you're not just purchasing equipment—you're partnering with us, a committed industry expert who understands your coating challenges and provides the right tools and solutions to overcome them.

Conclusion

Selecting the right finishing line for board production requires a strategic assessment of your board type, production volume, and desired surface finish. Whether you're considering roller coating, curtain coating, or spray painting, each technology has unique advantages suited to specific applications.

With the rising demands for surface aesthetics, environmental compliance, and operational efficiency, working with an experienced partner like PURETE can make all the difference. From tailored machine design to post-sale support, PURETE offers a comprehensive solution to help your business thrive in a competitive market.

Explore PURETE's coating technologies today and elevate your board production to a new standard of excellence.