Material Compatibility Guide for Wrapping Production Lines: PVC Film, Wood Veneer, CPL

September 26, 2025

September 26, 2025 Hits:565second

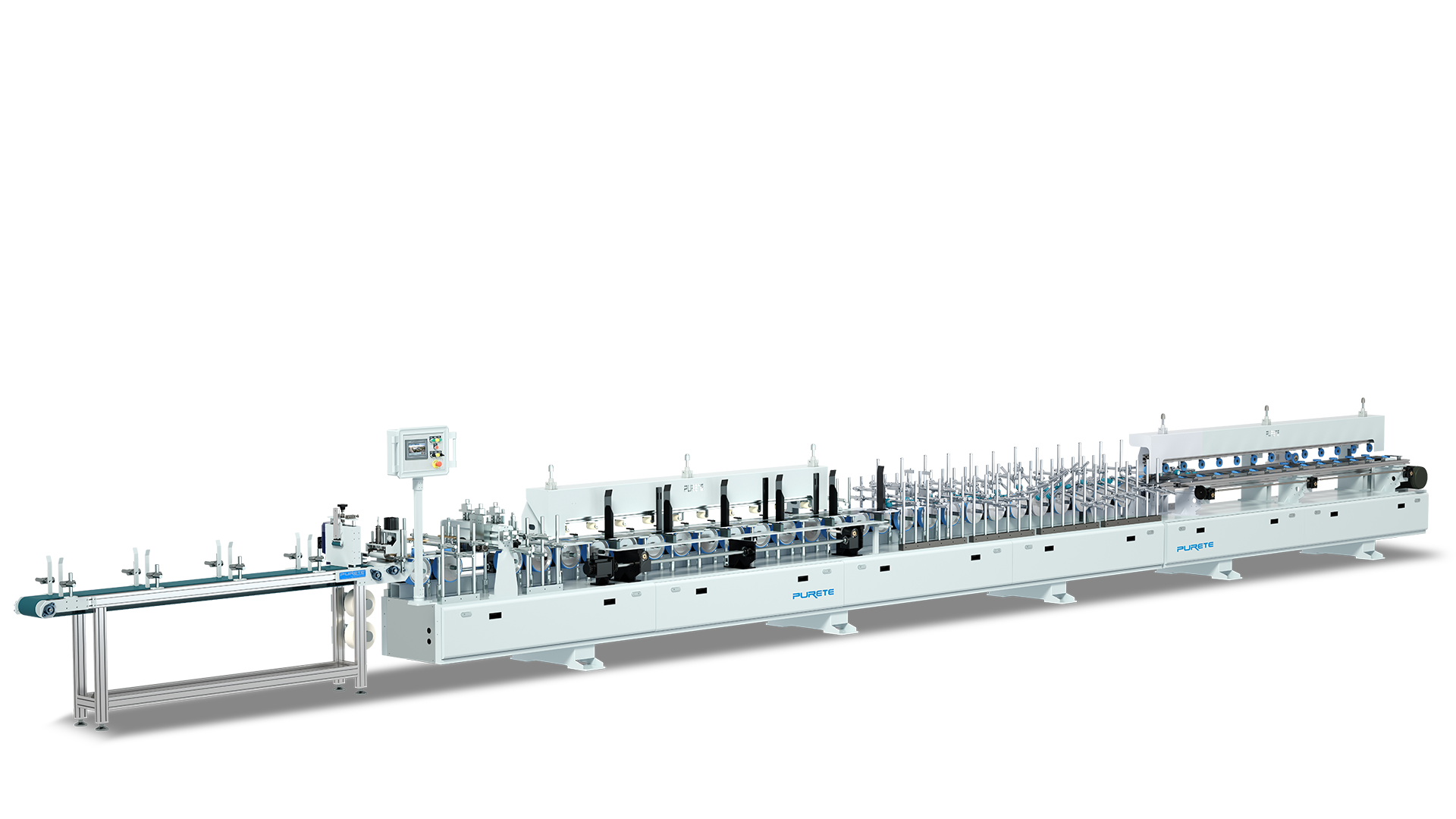

Hits:565secondIn the modern building materials and furniture industry, wrapping production lines have become indispensable. These automated systems enable manufacturers to apply decorative materials such as PVC film, wood veneer, and CPL (Continuous Pressure Laminate) onto substrates like MDF, particle board, aluminum, and even solid wood.

However, not every decorative material behaves the same way. Material compatibility is one of the most important factors when selecting or operating a wrapping production line. Choosing the wrong film or veneer—or pairing it with an incompatible substrate—can result in poor adhesion, surface defects, or costly waste.

This guide explores the characteristics of the most common wrapping materials, explains how they interact with different substrates, and shows how PURETE's advanced wrapping line technology ensures that manufacturers can handle multiple materials with one system.

Why Material Fit Matters in Wrapping?

The performance of a wrapping production line depends not only on the machinery but also on the interaction between wrapping films and substrates.

Key challenges when material compatibility is overlooked:

Adhesion issues: Some films or veneers may not bond well to certain substrates.

Surface defects: Bubbles, cracks, or peeling due to mismatched heat or pressure.

Durability concerns: Wrapping layers may fade, delaminate, or yellow prematurely.

Increased waste: Misalignment and defective finishes drive up production costs.

A well-designed wrapping production line should therefore support multi-material processing, allowing manufacturers to switch between PVC film, wood veneer, and CPL without sacrificing quality or efficiency.

PVC Film Benefits and Considerations

PVC (Polyvinyl Chloride) film is one of the most widely used wrapping materials in door, window, and furniture production.

Benefits:

Wide design options: Available in woodgrain, solid colors, metallic, or high-gloss finishes.

Cost-effective: Affordable compared to natural veneers or laminates.

Moisture resistant: Suitable for kitchens, bathrooms, and humid environments.

Easy processing: Works well with hot-melt and PUR adhesives.

Considerations:

PVC can be sensitive to temperature control. Too much heat can cause deformation.

Requires precise tension control on the wrapping line to avoid wrinkles.

Lower-end PVC films may yellow or fade under UV exposure, so proper material sourcing is essential.

With an optimized wrapping system like PURETE's, manufacturers can process PVC foils at high speeds (30–60 m/min) while maintaining consistent adhesion and surface quality.

Wood Veneer: Aesthetic Appeal Requires Gentle Handling

Natural wood veneer provides unmatched aesthetic appeal and authenticity. It is widely used for premium doors, moldings, and furniture trims.

Benefits:

Authentic look and texture: Natural grains and patterns enhance luxury appeal.

Eco-friendly: Uses thin layers of real wood, reducing timber consumption.

Premium positioning: Adds value to high-end products.

Considerations:

Veneers are fragile and prone to cracking if bending or tension is too high.

Requires gentle adhesive application and precise temperature control.

More expensive than synthetic films, meaning waste reduction is critical.

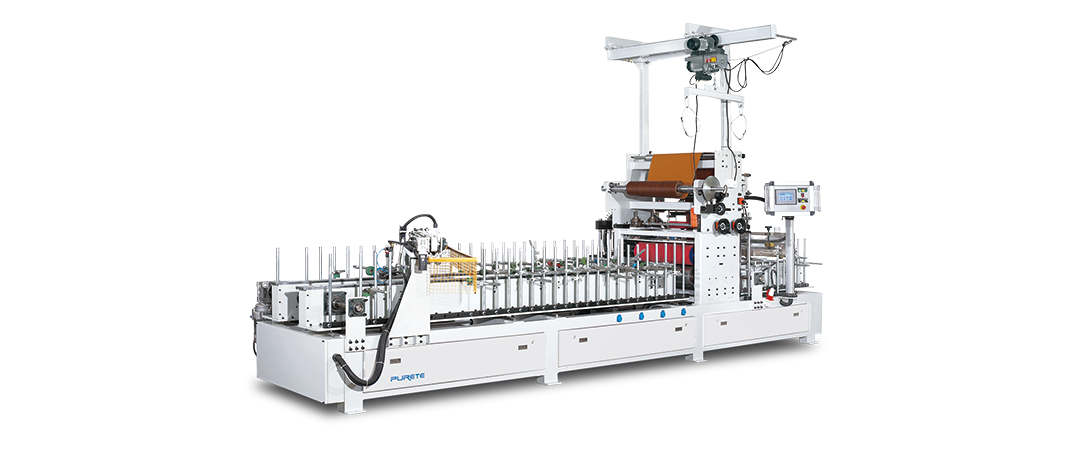

PURETE wrapping lines are engineered with precision heating and pressure systems to ensure wood veneer is handled gently yet firmly, preserving its beauty while reducing breakage.

CPL (Continuous Pressure Laminate): Durable and Heat-Resistant

CPL (Continuous Pressure Laminate) is becoming increasingly popular for doors, cabinets, and moldings that require durability and heat resistance.

Benefits:

High durability: Resistant to scratches, abrasion, and everyday wear.

Heat and chemical resistance: Suitable for kitchens and high-traffic areas.

Consistent appearance: Available in solid colors and decorative patterns.

Long lifespan: Retains finish quality over years of use.

Considerations:

Thicker and less flexible than PVC films, requiring stronger pressing and bonding.

May demand higher temperature adhesive systems for proper adhesion.

Slightly higher energy consumption during processing.

PURETE's wrapping technology is designed to balance adhesive performance, heat distribution, and pressing force, making it possible to wrap CPL efficiently without compromising on quality.

How to Match Materials with MDF, Particle Board, Aluminum, Solid Wood

Different substrates react differently to wrapping materials, and understanding these interactions ensures consistent results:

MDF (Medium-Density Fiberboard): Works well with PVC, veneer, and CPL due to its smooth surface. Adhesion is typically strong, but dust removal is critical.

Particle Board: Lower density than MDF, requiring high-quality adhesive and pressure control. Best paired with PVC or CPL for cost-effective solutions.

Aluminum: Demands advanced adhesive technology and precise tension control. PVC and CPL are more commonly used than veneer on aluminum.

Solid Wood: Naturally strong but prone to expansion/contraction. Veneer wrapping offers authentic finishes, while CPL adds durability.

PURETE systems are built for multi-material versatility, ensuring manufacturers can run all these substrate-material combinations on one line without constant reconfiguration.

PURETE Wrapping Line Design: Handles Multiple Materials with One System

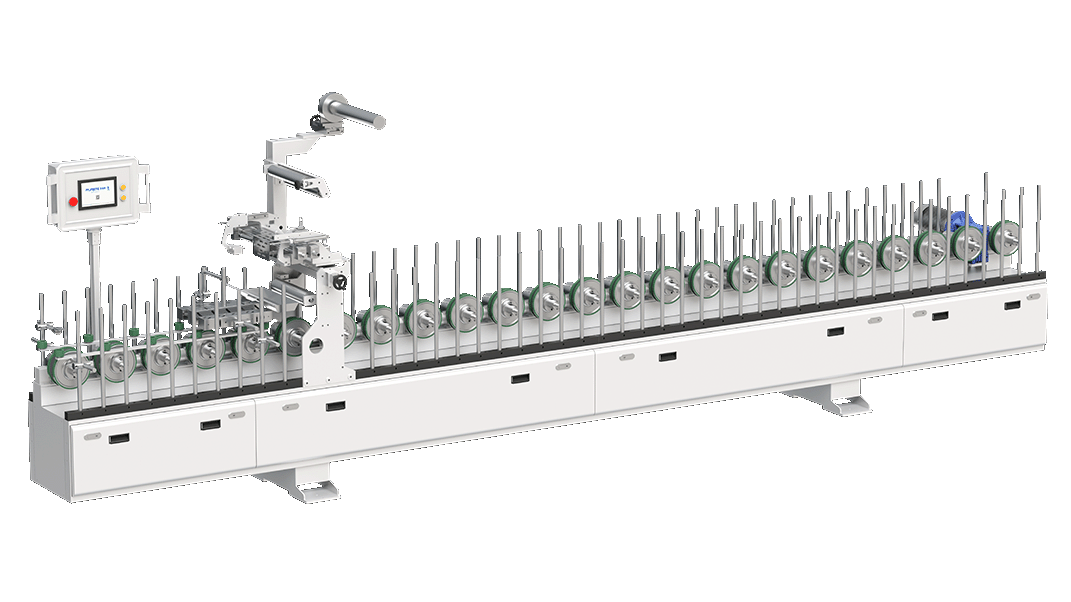

While many wrapping machines are optimized for just one material type, PURETE wrapping production lines stand out for their multi-material adaptability.

Key advantages include:

Universal adhesive systems: Compatible with hot-melt and PUR adhesives.

Precision controls: Accurate temperature, tension, and pressure management for PVC, veneer, and CPL.

Rapid changeover: Switch between materials with minimal downtime.

Consistent quality: Automated alignment and inspection systems reduce waste and ensure flawless finishes.

Trusted brand: PURETE is a global leader known for customization, reliability, and efficient wrapping solutions.

For manufacturers who need flexibility, durability, and efficiency, PURETE's wrapping lines provide a future-proof investment.

Conclusion

Material compatibility is the foundation of successful wrapping operations. Whether working with PVC film, natural wood veneer, or CPL, each material requires careful handling, precise adhesive control, and substrate matching to achieve flawless results.

By choosing PURETE wrapping production lines, manufacturers gain a system designed to process multiple materials with ease, reduce waste, and maximize ROI. From MDF trims to aluminum frames, PURETE ensures that every wrapped product delivers the durability, beauty, and consistency the market demands.