MDF, Plywood, or Particle Board? Best Coating Technologies for Different Substrates

August 26, 2025

August 26, 2025 Hits:1411second

Hits:1411secondEngineered wood products such as MDF (Medium Density Fiberboard), Plywood, and Particle Board have become staples in modern furniture manufacturing, interior design, and flooring due to their versatility, affordability, and ease of customization. Each of these substrates possesses unique structural and surface properties that directly influence how coatings adhere, perform, and appear.

Selecting the right coating technology is crucial not only for aesthetics but also for durability, moisture resistance, and cost efficiency. A wrong choice can result in peeling, uneven surfaces, or reduced product lifespan, which is especially important for furniture, interior panels, and flooring.

In this article, we explore the characteristics of MDF, plywood, and particle board, examine their surface challenges, and compare leading coating technologies, including roller coating, spray painting, PUR laminating, and curtain coating. We also highlight real-world PURETE application examples and explain how PURETE's full range of solutions can cater to every substrate type.

Properties of MDF, Plywood, and Particle Board

MDF (Medium Density Fiberboard)

MDF is made by compressing fine wood fibers with adhesives, resulting in a smooth, uniform, and dense material. This uniformity provides a consistent surface, ideal for high-quality coatings.

Advantages:

Smooth surface with minimal grain, reducing the need for heavy sanding or fillers.

High density ensures strong adhesion of finishes, especially high-gloss coatings favored in premium markets.

Easy to machine, cut, and shape, making it suitable for intricate furniture designs.

Limitations:

Sensitive to moisture; edges can swell if not sealed properly.

Requires careful handling to avoid chipping during processing.

Applications: Cabinet doors, wall panels, decorative boards, and luxury furniture with glossy finishes.

Plywood

Plywood consists of thin wood veneers glued in alternating layers, offering excellent strength and resistance to warping. Its layered construction makes it a preferred choice where structural integrity is needed.

Advantages:

High mechanical strength and stability.

Can support heavier furniture components and flooring.

Retains natural wood aesthetics, allowing for stains or transparent finishes.

Limitations:

Natural grain variations can lead to uneven absorption of coatings.

Requires proper priming or sealing to achieve consistent finish quality.

Applications: Flooring, furniture frames, wall panels, and areas requiring both strength and visual appeal.

Particle Board

Particle board is manufactured from wood chips, sawdust, and resin, making it a highly cost-effective alternative to MDF or plywood.

Advantages:

Affordable and widely available.

Lightweight and easy to handle.

Suitable for budget furniture and shelving solutions.

Limitations:

Porous and less dense, making it prone to absorbing coatings unevenly.

Requires sealing or lamination to improve durability and moisture resistance.

Applications: Low-cost furniture, countertops, shelving, and interior panels where budget constraints are a priority.

Surface Challenges and How They Impact Coating Results

Different substrates present distinct surface challenges that directly affect coating results:

MDF Challenges: Its smooth surface makes it ideal for high-gloss coatings, but edges are prone to absorbing excess paint or lacquer, leading to swelling or uneven gloss. Edge sealing or PUR lamination is crucial for protecting against moisture and wear.

Plywood Challenges: The natural veneer layers and grain variations can lead to color inconsistencies and uneven coating absorption. Using primer layers and roller coating or spray painting can help achieve uniform finishes while preserving the natural wood look.

Particle Board Challenges: Highly porous surfaces absorb coatings unevenly, often resulting in a dull appearance or rough texture. Laminating with PUR hot-melt adhesives or applying multiple coats improves surface uniformity, durability, and moisture resistance.

Roller Coating vs Spray Painting vs PUR Laminating vs Curtain Coating: Which Is Better?

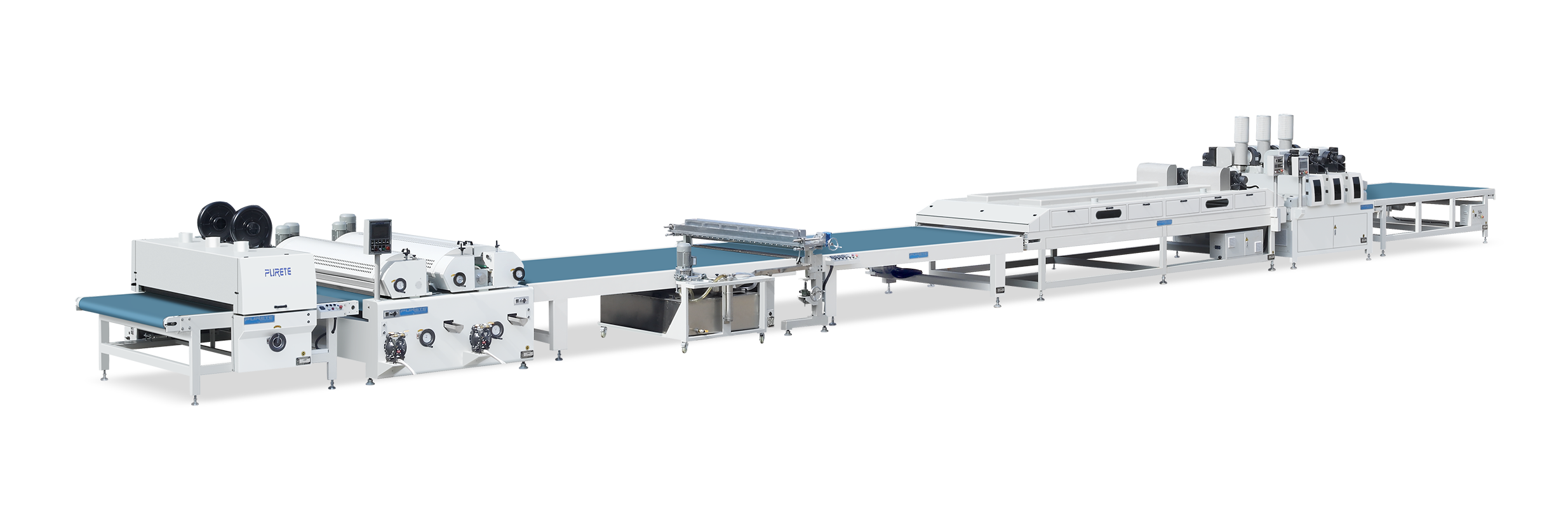

Roller Coating

Mechanism: Uses rollers to apply liquid coatings evenly over flat surfaces.

Best for: Flat MDF and plywood panels.

Pros:

High efficiency for large-scale production.

Consistent thickness reduces defects and material waste.

Cost-effective for large runs of standard-sized panels.

Cons:

Limited to flat surfaces; not suitable for edges or complex designs.

Less flexibility in creating textured or custom finishes.

Spray Painting

Mechanism: Coatings are atomized into a fine mist and sprayed onto surfaces. Can be manual or automated.

Best for: Furniture and panels with intricate designs, grooves, or edges.

Pros:

Flexibility in textures, color variety, and decorative finishes.

Suitable for customized or small-batch production.

Can achieve special effects, such as matte, metallic, or textured finishes.

Cons:

Higher material consumption and waste.

Slower than roller coating for mass production.

PUR Laminating (Polyurethane Reactive Hot-Melt)

Mechanism: Uses hot-melt adhesives to bond decorative foils or films onto panels, creating durable, moisture-resistant finishes.

Best for: MDF edges, particle board surfaces, flooring, and decorative interior panels.

Pros:

Excellent adhesion, moisture, and heat resistance.

Ideal for high-traffic or high-use furniture and flooring.

Produces smooth, consistent finishes even on porous substrates.

Cons:

Higher initial investment in equipment.

Requires precise temperature and pressure control.

Curtain Coating

Mechanism: A continuous liquid curtain flows over panels, creating uniform coverage.

Best for: MDF boards requiring high-gloss finishes, especially in markets like India, where glossy wall panels, doors, and decorative boards are highly desired.

Pros:

High-speed coating suitable for mass production.

Consistent, defect-free finish.

Excellent for premium products and high-gloss furniture.

Cons:

Only suitable for flat panels.

High initial equipment cost.

Application Examples from PURETE (Furniture, Flooring, Interior Panels)

Furniture:

MDF cabinets coated with curtain coating for high-gloss finishes.

Particle board shelves laminated with PUR films for durability and moisture protection.

Flooring:

Plywood flooring treated with roller coating for wear resistance and uniform color.

Particle board subflooring is laminated for enhanced moisture resistance.

Interior Panels:

MDF wall panels coated with curtain systems for glossy decorative finishes.

Plywood panels are spray-painted to showcase natural wood grain while ensuring uniform protection.

PURETE's solutions ensure consistent coating quality, automation efficiency, and energy savings, making them ideal for global furniture and interior panel manufacturers.

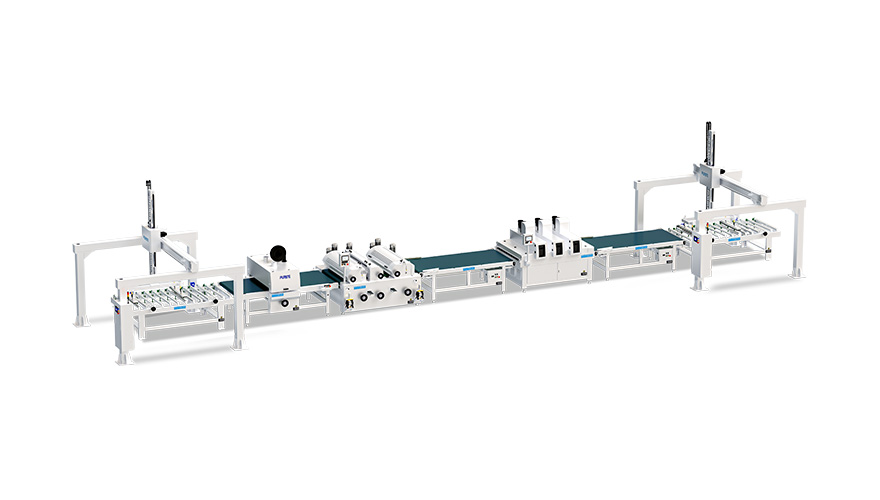

PURETE's Full Range of Solutions for All Panel Types

As a global leader in coating technology, PURETE provides tailored solutions for every substrate:

MDF: Curtain coating and PUR laminating for high-gloss panels, cabinets, and decorative boards.

Plywood: Roller coating and spray painting for natural grain or textured finishes.

Particle Board: PUR laminating to enhance durability, moisture resistance, and overall surface quality.

PURETE equipment is recognized for precision, reliability, and long-term efficiency, allowing manufacturers to produce premium-quality panels while optimizing production costs.

Conclusion

Choosing the right substrate and coating technology is crucial for furniture, flooring, and interior panel manufacturing. MDF, plywood, and particle board each offer unique advantages and require specific finishing techniques:

Curtain coating: Best for high-gloss MDF panels and mass production.

Roller coating: Ideal for flat plywood and MDF panels.

Spray painting: Flexible, perfect for custom designs and complex shapes.

PUR laminating: Essential for particle board and edges to enhance durability and moisture resistance.

For manufacturers aiming to meet modern consumer demands—whether in high-gloss MDF panels, decorative boards, or durable laminated particle boards—partnering with PURETE ensures access to advanced coating solutions that combine quality, efficiency, and versatility.

With PURETE, businesses can produce premium furniture, flooring, and interior panels that meet market expectations while optimizing operational efficiency.