Profile Wrapping Machine Applications in Modern Furniture Production

January 15, 2026

January 15, 2026 Hits:14second

Hits:14secondAs furniture design trends move toward cleaner lines, customized profiles, and premium surface finishes, manufacturers are under growing pressure to deliver high-quality decorative components at scale. Traditional finishing methods such as spray painting or manual laminating often struggle to meet modern demands for consistency, efficiency, and environmental compliance.

This is where profile wrapping machines have become an essential part of contemporary furniture production. By enabling continuous, automated wrapping of decorative foils onto shaped profiles, profile wrapping technology supports both mass production and flexible customization. From MDF moldings to aluminum frames, profile wrapping machines now play a key role across cabinet, door, panel, and furniture component manufacturing.

This article explores how profile wrapping machines work, their core applications in modern furniture production, the advantages of profile wrapping technology, emerging automation trends, and how to choose the right profile wrapping machine supplier—with a practical look at how PURETE supports furniture and panel factories worldwide.

How a Profile Wrapping Machine Works

A profile wrapping machine is designed to apply decorative films—such as PVC, PET, PP, veneer, or CPL—onto linear or shaped substrates using heat and adhesive under controlled pressure.

Core Working Process

Although machine configurations vary, most profile wrapping machines follow a similar workflow:

Profile Feeding and Alignment

The substrate (MDF, particleboard, solid wood, aluminum, or PVC) is fed into the machine and precisely guided to ensure stable positioning.

Adhesive Application

Hot-melt adhesives—commonly PUR (polyurethane reactive) or EVA—are applied evenly to the surface of the profile. PUR is increasingly preferred for furniture applications due to its superior heat, moisture, and chemical resistance.

Film Heating and Pre-Forming

Decorative foils are heated to improve flexibility, allowing them to conform smoothly to complex contours, grooves, and edges.

Wrapping and Pressing

A series of pressure rollers and belts wrap the film tightly around the profile, ensuring uniform bonding without bubbles or wrinkles.

Cooling and Cutting

Once bonded, the wrapped profile cools and is cut to the required length, ready for downstream processing or assembly.

Compatible Materials and Profiles

Modern profile wrapping machines can handle:

Flat, L-shaped, U-shaped, and irregular profiles

Straight and slightly curved components

Wood-based panels, plastics, and metal substrates

This versatility makes profile wrapping ideal for a wide range of furniture components.

Key Applications in Modern Furniture Production

Profile wrapping technology is widely used across multiple segments of the furniture industry, supporting both aesthetic and functional requirements.

1. Cabinet Doors and Frames

Kitchen and bathroom cabinets rely heavily on wrapped profiles for door frames, rails, and stiles. Profile wrapping enables manufacturers to:

Achieve seamless woodgrain or solid-color finishes

Match door frames with flat laminated panels

Produce moisture-resistant surfaces for kitchens and bathrooms

Wrapped cabinet profiles also eliminate visible joints, enhancing perceived product quality.

2. Furniture Moldings and Decorative Trim

Decorative moldings—such as skirting boards, cornices, and edge trims—are classic applications for profile wrapping machines. Compared with painting, wrapping provides:

Consistent surface appearance

Scratch-resistant decorative layers

Reduced finishing time and labor cost

This is especially valuable for large-volume production of standardized components.

3. Wardrobes and Storage Systems

Modern wardrobes increasingly feature aluminum or MDF profiles with premium surface finishes. Profile wrapping allows manufacturers to:

Wrap aluminum frames with decorative films

Create uniform finishes across doors, frames, and accessories

Support modular furniture systems with interchangeable profiles

The result is improved design flexibility without compromising production efficiency.

4. Office Furniture Components

In office furniture production, profile wrapping machines are commonly used for:

Desk edges and support frames

Partition system profiles

Drawer and shelf components

Wrapped profiles provide durability while maintaining a clean, professional aesthetic suited to commercial environments.

5. Panel Furniture and Hybrid Lines

Many factories operate flat laminating lines and profile wrapping lines side by side. Profile wrapping machines complement flat lamination by handling edges and shaped components, ensuring a unified appearance across panel furniture products.

Advantages of Profile Wrapping Technology

Several key advantages drive the growing adoption of profile wrapping machines in furniture factories.

Superior Surface Quality

Profile wrapping produces seamless, uniform finishes with precise detail reproduction. Decorative foils can accurately replicate woodgrain, stone, fabric, or matte textures, meeting modern design expectations.

High Production Efficiency

Compared with manual finishing or spray coating, profile wrapping offers:

Continuous operation

Faster throughput

Reduced rework and scrap

This makes it ideal for medium- to large-scale furniture production.

Material and Cost Savings

Profile wrapping minimizes overspray, waste, and material loss. Adhesives and films are applied efficiently, helping manufacturers control production costs while maintaining consistent quality.

Environmental Benefits

Using PUR adhesives and film wrapping significantly reduces VOC emissions compared with traditional painting. This supports compliance with increasingly strict environmental regulations in global furniture markets.

Design Flexibility

With a wide range of decorative films available, manufacturers can quickly adapt to changing market trends without altering core production processes.

Automation Trends in Profile Wrapping Lines

Automation is transforming profile wrapping from a standalone process into a fully integrated production solution.

Smart Control Systems

Modern profile wrapping machines feature PLC control, touch-screen interfaces, and digital recipe management. This allows operators to:

Switch profiles quickly

Store wrapping parameters

Reduce setup time and operator error

Inline Integration

Profile wrapping lines are increasingly integrated with:

CNC profile machining centers

Automatic feeding and stacking systems

Flat laminating and edge banding lines

This creates a continuous, automated furniture production workflow.

Energy-Efficient Heating and Adhesive Systems

Advanced heating modules and optimized PUR glue units improve energy efficiency while maintaining stable bonding performance.

Data-Driven Production

Some high-end systems support production monitoring and fault diagnostics, helping factories improve uptime and process consistency.

Choosing a Profile Wrapping Machine Supplier

Selecting the right supplier is critical for long-term performance and return on investment.

Key Evaluation Factors

When choosing a profile wrapping machine supplier, furniture manufacturers should consider:

Machine stability and wrapping accuracy

Compatibility with PUR adhesives and decorative films

Customization options for different profile types

Technical support and global service capability

Proven experience in furniture and panel production

Why Experience Matters

Profile wrapping is highly process-dependent. Suppliers with deep industry experience understand how materials, adhesives, temperature, and pressure interact—ensuring reliable results across diverse applications.

PURETE Provides Complete Wrapping Solutions Tailored to Furniture and Panel Factories

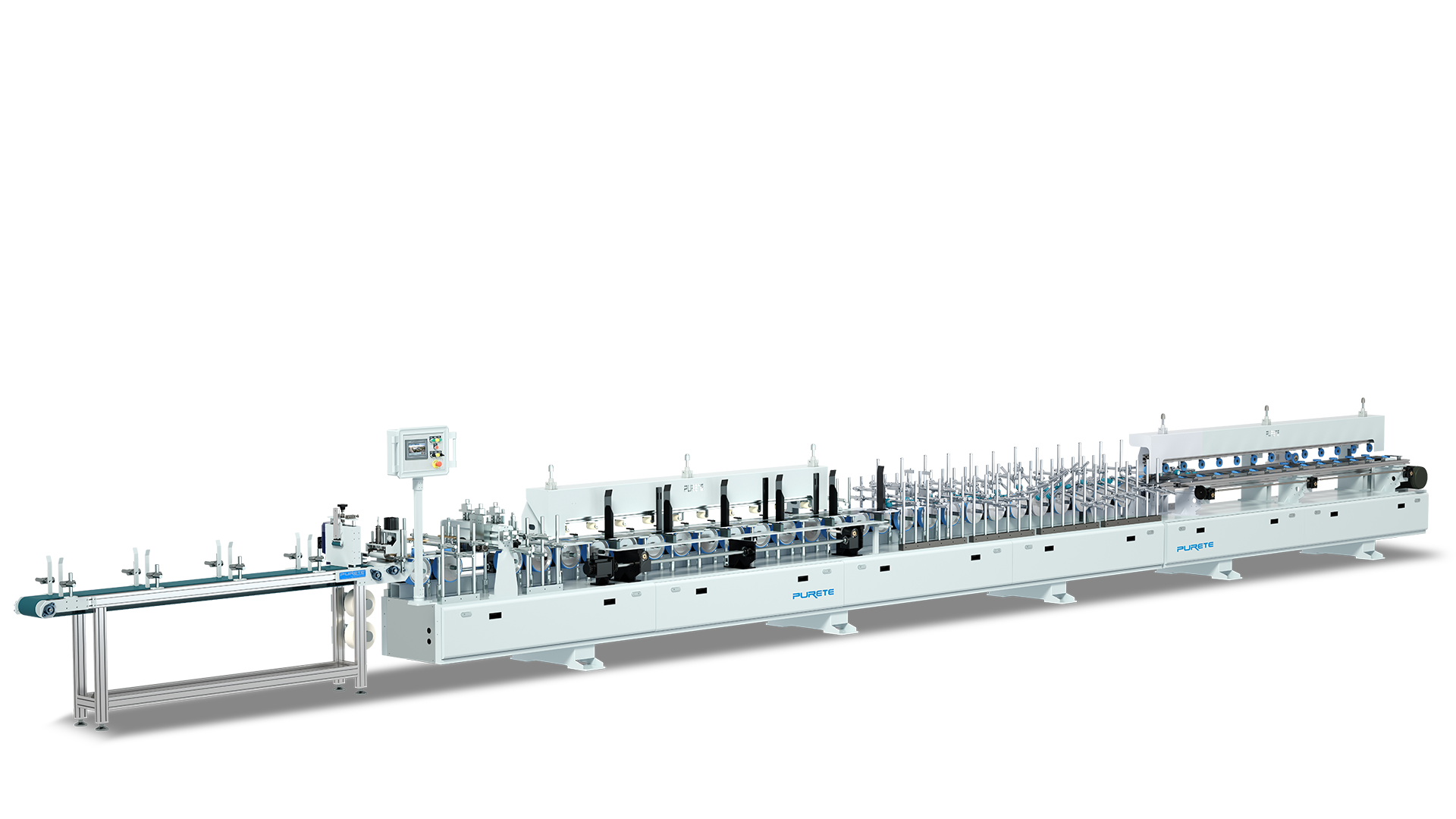

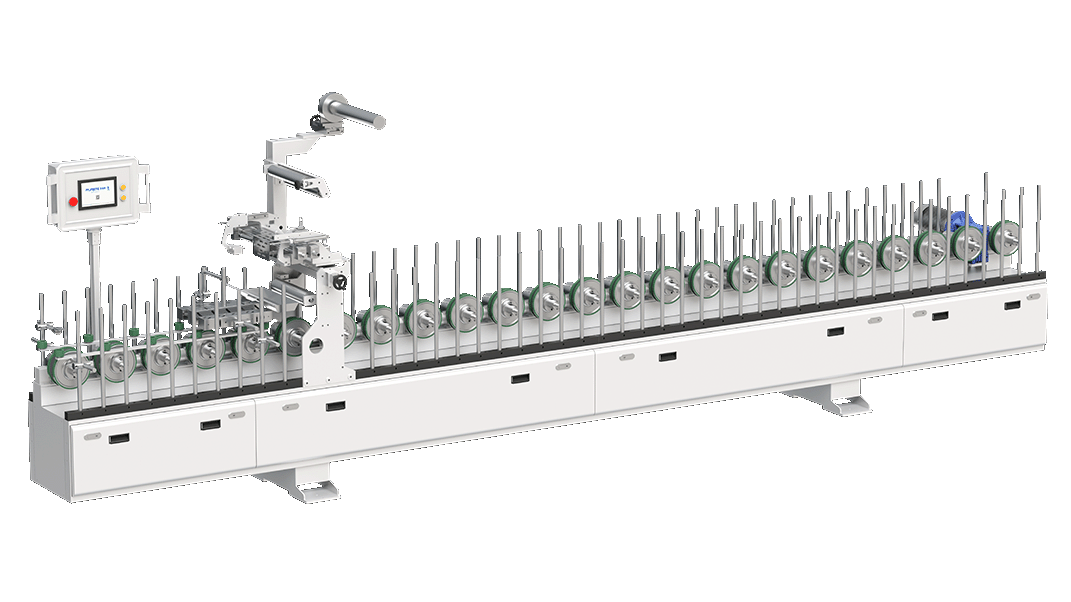

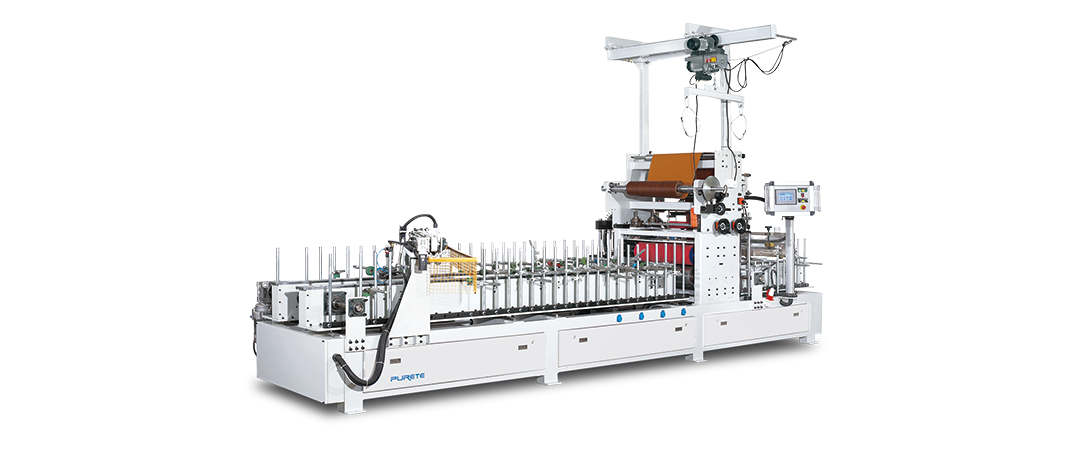

PURETE is widely recognized in the woodworking and furniture machinery industry for providing complete surface finishing and wrapping solutions. The company's profile wrapping systems are designed specifically for furniture and panel factories seeking stable performance, automation compatibility, and consistent surface quality.

Rather than offering standalone machines alone, PURETE focuses on integrated solutions, supporting:

Profile wrapping machines compatible with PUR and multiple decorative films

System layouts optimized for furniture production lines

Seamless integration with flat laminating, CNC machining, and downstream handling systems

With strong engineering capabilities and a global market presence, PURETE solutions are well-suited for manufacturers aiming to upgrade production efficiency while maintaining high aesthetic standards.

Conclusion

Profile wrapping machines have become a cornerstone of modern furniture production, enabling manufacturers to deliver premium finishes, consistent quality, and scalable output. From cabinet doors and moldings to wardrobes and office furniture components, profile wrapping technology supports both functional performance and design flexibility.

As automation, material innovation, and environmental standards continue to evolve, profile wrapping lines will play an even more strategic role in furniture factories worldwide. Choosing the right equipment—and the right solution provider—is essential for long-term success.

By combining proven technology, automation-ready systems, and application-focused expertise, companies like PURETE help furniture and panel manufacturers stay competitive in an increasingly demanding global market.