Smart Wrapping Production Lines: From Material Feeding to Final Quality Control

September 28, 2025

September 28, 2025 Hits:442second

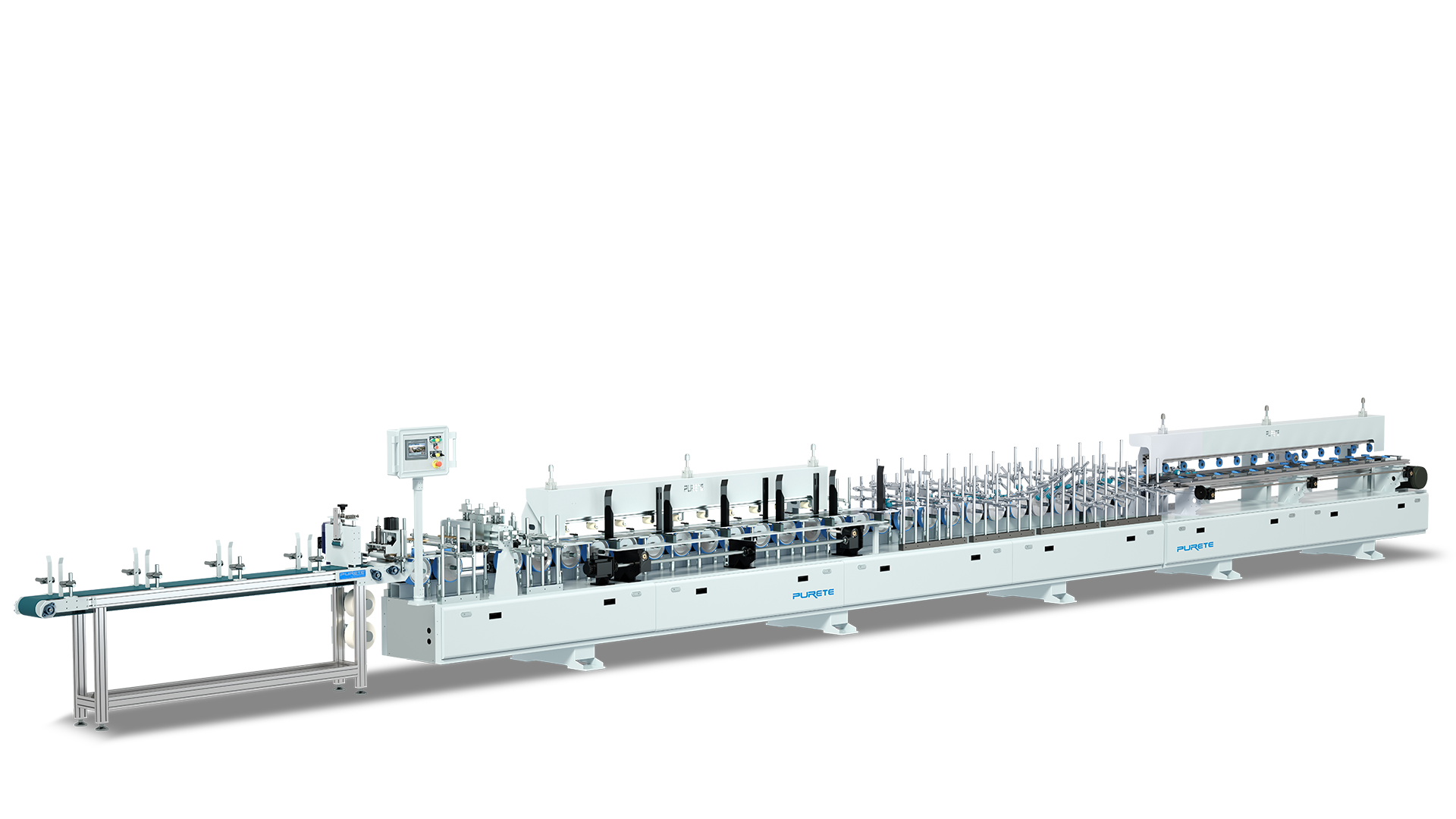

Hits:442secondIn today's competitive manufacturing landscape, efficiency, consistency, and scalability define success. Whether producing doors, windows, furniture panels, or decorative moldings, manufacturers face pressure to meet rising demand while reducing costs. This is where smart wrapping production lines come into play. Unlike conventional wrapping systems, which often rely on manual intervention and fragmented processes, smart wrapping lines integrate automation, real-time monitoring, and advanced control systems. From material feeding to final quality control, these lines represent a transformative shift in how wrapping is done for PVC film, wood veneer, and laminate applications.

This article explores what makes a wrapping production line " smart,'' the advantages of integrated systems, key applications in industries such as furniture and interior design, and why PURETE Wrapping Production Lines stand out as a reliable choice for modern manufacturers.

What Makes a Wrapping Production Line ''Smart''?

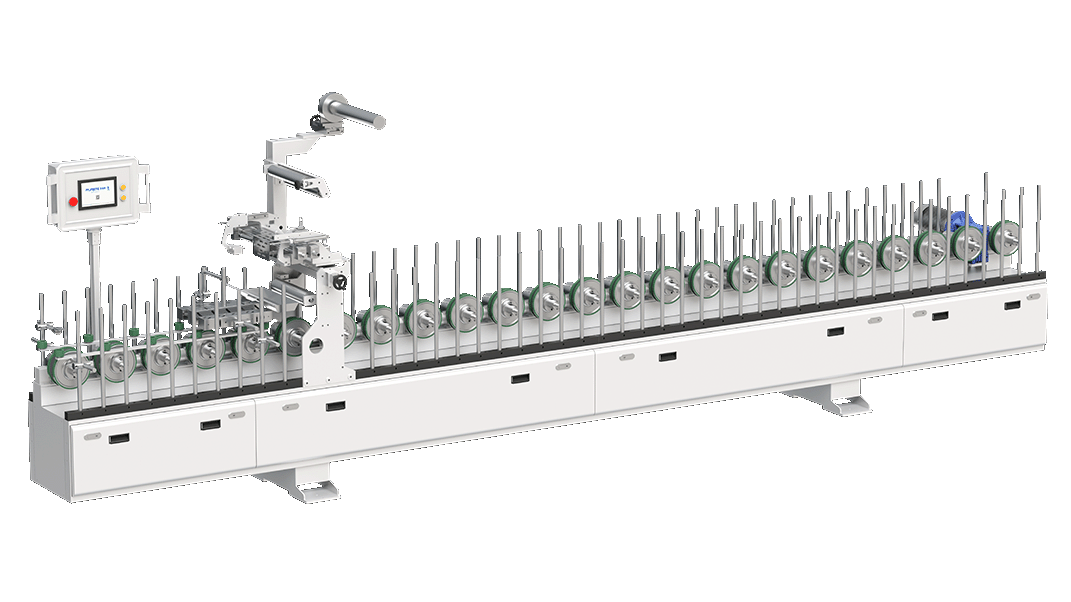

A smart wrapping production line is defined by its ability to combine multiple stages of the wrapping process into a seamless, automated workflow. Instead of treating material feeding, gluing, wrapping, trimming, and quality inspection as separate steps, smart lines integrate them into one continuous system.

Key characteristics include:

Automated Material Feeding: Minimizes manual handling errors and ensures continuous operation.

Precision Glue Application: Sensors and automated glue heads adjust dosage to reduce waste and ensure even coating.

Adaptive Wrapping Mechanisms: Adjust pressure and temperature for different wrapping materials such as PVC films, CPL laminates, or natural wood veneers.

Integrated Quality Control: Real-time monitoring detects defects like bubbles, wrinkles, or delamination before final packaging.

Data-Driven Operation: Smart control panels collect performance data, enabling predictive maintenance and optimizing production speed.

This intelligent coordination not only improves accuracy and repeatability but also reduces downtime and human dependency.

Benefits of Integrated Wrapping Production Lines

Switching from traditional wrapping equipment to a smart integrated wrapping line brings a wide range of advantages:

1. Higher Efficiency and Faster Throughput

Because the entire process is continuous—from feeding substrates like MDF, particle board, or aluminum profiles to finishing—the line minimizes idle time. Manufacturers achieve higher output per shift without compromising quality.

2. Consistent Quality Across Batches

Manual wrapping often results in inconsistencies, especially when different operators are involved. Smart systems standardize every stage, ensuring each panel, door frame, or molding comes out with a uniform finish.

3. Reduced Waste and Lower Costs

Automated glue application and precise material handling prevent overuse of adhesives or films. This reduces raw material costs, improves sustainability, and lowers the carbon footprint of operations.

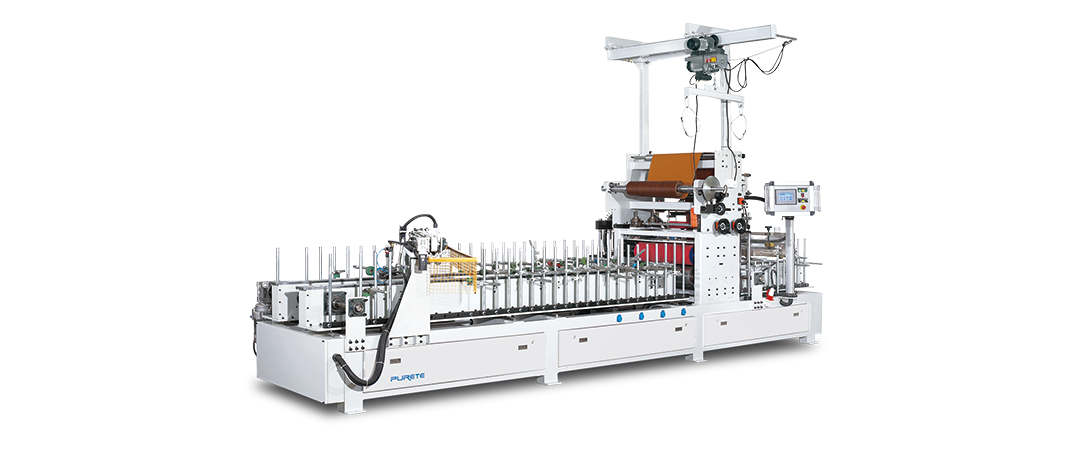

4. Flexibility in Material Handling

Smart wrapping lines are designed to handle diverse materials—PVC decorative film, natural wood veneers, CPL laminates, PET foil, or paper overlays—making them ideal for manufacturers with varied product lines.

5. Improved Workplace Safety

By reducing manual labor and repetitive handling, integrated systems enhance operator safety while allowing workers to focus on monitoring and supervision.

6. Digital Monitoring and Predictive Maintenance

Through sensors and IoT integration, smart lines alert operators about potential failures before they occur. This proactive approach minimizes costly downtime.

Key Applications in Furniture and Interior Industries

The versatility of smart wrapping lines makes them indispensable in industries that demand both aesthetic appeal and functional durability.

1. Furniture Manufacturing

Smart wrapping lines are heavily used in wrapping MDF furniture panels, shelves, and cabinet profiles. Decorative films and laminates add scratch resistance and water resistance while maintaining a premium finish.

2. Door and Window Frames

Wood, MDF, or aluminum door and window profiles are wrapped with PVC films or CPL laminates to improve durability, thermal stability, and design consistency.

3. Wall Panels and Moldings

Decorative trims, skirtings, and wall panels benefit from consistent wrapping quality, ensuring smooth finishes for residential and commercial interiors.

4. Kitchen and Bathroom Applications

Because CPL and PVC films offer moisture resistance, wrapping lines are essential in producing cabinets and bathroom furniture components.

5. Retail and Office Fixtures

Modern retail displays and office partitions increasingly rely on wrapped MDF or composite materials for both cost-efficiency and sleek design.

By covering such diverse applications, smart wrapping lines help manufacturers expand their product portfolios and serve both budget-conscious and premium markets.

Why Choose PURETE Wrapping Production Line

Among global suppliers, PURETE has established itself as a leading brand known for innovation, reliability, and adaptability in wrapping production technology. Here's why PURETE stands out:

Multi-Material Compatibility: PURETE wrapping lines handle PVC, PET, CPL, veneer, and decorative foils with ease, making them suitable for door, window, and molding industries.

Tailored Automation Levels: From semi-automatic solutions for small workshops to fully automated smart lines for industrial-scale production, PURETE designs systems to fit customer needs.

Precision and Clean Operation: Advanced glue application and inert curing systems ensure minimal waste and high cleanliness standards.

Proven ROI: By reducing downtime, material waste, and labor dependency, PURETE systems deliver measurable cost savings over time.

Global Trust: As a recognized brand in surface finishing and wrapping solutions, PURETE has a reputation for durable machines and long-term customer support.

For manufacturers seeking both efficiency and product quality, PURETE's smart wrapping production lines offer the optimal balance of cost-effectiveness and performance.

Conclusion

The future of surface finishing lies in smart, integrated wrapping production lines. By automating material feeding, ensuring precision glue application, streamlining wrapping, and incorporating final quality control, these systems redefine how doors, windows, furniture, and trims are produced.

The benefits are clear: higher efficiency, consistent quality, material flexibility, and cost savings. As industries demand faster throughput and greater customization, smart lines are no longer optional—they are essential.

For manufacturers seeking a trusted partner in this transformation, PURETE Wrapping Production Lines provide unmatched versatility, reliability, and return on investment. Choosing PURETE means investing not only in advanced machinery but also in sustainable, scalable, and future-ready production.