Spray Painting Production Line: Key Considerations for Industrial Furniture Manufacturing

August 22, 2025

August 22, 2025 Hits:794second

Hits:794secondIn the highly competitive furniture industry, industrial-scale spray painting production lines have become a critical investment for manufacturers seeking to achieve efficiency, consistency, and high-quality finishes. Whether producing MDF panels, particle boards, cabinets, or complete furniture sets, automated spray coating technology ensures that surfaces meet both aesthetic and durability standards demanded by today's market.

As global demand for stylish and eco-friendly furniture rises, spray painting systems provide a way to balance fast production with superior surface finishing. This article explores what a spray painting production line is, which materials are best suited, the benefits it offers, key equipment components, and how PURETE delivers customized spray coating solutions for industrial manufacturers.

What Is a Spray Painting Production Line?

A spray painting production line is a fully or semi-automated system designed to apply coatings—such as paints, lacquers, or UV finishes—onto furniture components and panels. Unlike manual spraying, which can be inconsistent, automated lines guarantee uniform coverage, faster application speeds, and reduced material waste.

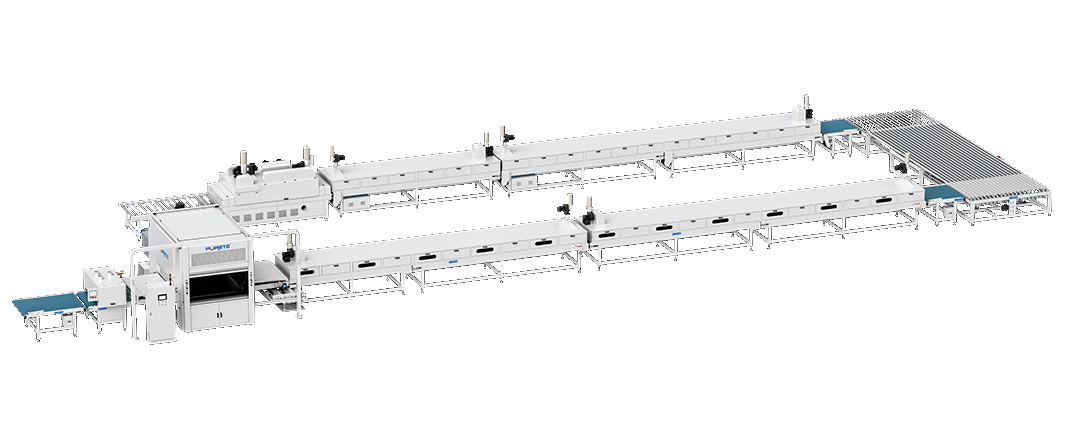

Typical spray coating lines include conveyors, spray booths, automatic spray guns, and curing systems, all integrated to create a continuous and efficient process. These systems are widely used in:

Furniture panel finishing (MDF, particle board, plywood)

Cabinet doors and kitchen panels

Interior decorative components

High-volume furniture manufacturing plants

By investing in a spray painting line, furniture producers achieve higher output capacity while ensuring consistent surface quality across all products.

Types of Furniture Materials Best Suited for Spray Coating

Spray coating technology is versatile and can be applied to multiple materials used in industrial furniture production. The most common include:

MDF (Medium-Density Fiberboard) – Ideal for smooth, uniform finishes, especially in cabinets and decorative panels.

Particle Boards – Often used in cost-effective furniture, spray coating enhances surface durability and visual appeal.

Solid Wood – High-end furniture often requires clear lacquer or paint finishes to highlight natural grain while providing protection.

Plywood and Veneered Panels – Spray coating provides color flexibility while preserving the layered structure.

Composite Materials and Laminated Surfaces – Coatings improve resistance to scratches, moisture, and chemicals.

By adapting spray coating technology to these substrates, manufacturers can cater to different furniture market segments, from budget-friendly mass production to premium luxury interiors.

Benefits: Fast Application, Consistent Finish, Color Flexibility

A spray painting production line provides a range of benefits that make it indispensable for industrial furniture manufacturing:

Fast Application – Automated spray guns can coat multiple panels within seconds, drastically reducing production times.

Consistent Finish – Unlike manual spraying, automated lines ensure uniform thickness and flawless application across all surfaces.

Color Flexibility – Spray systems support a wide range of colors, textures, and finishes (matte, satin, or high-gloss), allowing manufacturers to meet diverse design demands.

Durability – Coatings applied by automated systems are more resistant to scratches, stains, and humidity, extending furniture's lifespan.

Cost Savings – By optimizing paint usage and minimizing overspray, manufacturers reduce waste and overall production costs.

For companies that want to scale up production while maintaining high-quality decorative surfaces, spray painting lines are a proven solution.

Equipment Components to Look For (Booths, Guns, Conveyors)

When evaluating a spray painting production line, manufacturers should pay attention to several key components that determine efficiency and finish quality:

Spray Booths – Enclosed spaces that control overspray, ventilation, and dust. High-quality booths ensure a clean finish free from surface defects.

Spray Guns/Robotic Arms – Automated spray guns or robotic sprayers guarantee precision and consistency. Adjustable settings allow for customized coating thickness and coverage.

Conveyors – Transport panels and components through the line efficiently. Roller conveyors and belt systems can be tailored to fit production needs.

Drying & Curing Systems – Essential for ensuring coatings set correctly. Options include infrared, UV, or hot-air curing systems, depending on the coating type.

Control Systems – Digital control panels and monitoring systems enable easy adjustment of spray parameters, speed, and pressure, ensuring reliable production.

Selecting the right equipment setup ensures not only higher productivity but also greater long-term reliability.

Environmental and Safety Considerations

With stricter regulations on emissions and workplace safety, environmental and safety factors must be considered when investing in a spray coating line:

VOC (Volatile Organic Compounds) Reduction – Modern spray booths are equipped with filtration and exhaust systems that minimize harmful emissions.

Eco-Friendly Coatings – Water-based paints and UV-cured coatings reduce environmental impact while ensuring high-quality finishes.

Energy Efficiency – Optimized drying systems lower energy consumption.

Worker Safety – Enclosed booths, proper ventilation, and automated spraying reduce human exposure to chemicals.

By addressing these aspects, manufacturers not only comply with international environmental standards but also gain a sustainable competitive advantage in the market.

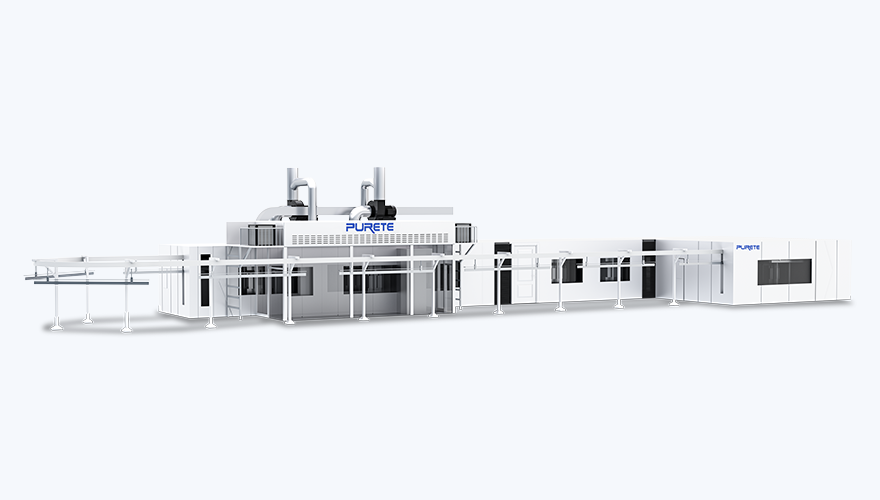

PURETE's Customized Spray Coating Lines for Industrial Use

As a global leader in laminating and surface finishing technologies, PURETE provides advanced spray coating production lines tailored to the needs of industrial furniture manufacturers.

PURETE's Key Advantages:

Customized Solutions – PURETE designs spray painting lines adapted to different materials, finishes, and production capacities.

Automation Integration – From conveyors to robotic spray guns, PURETE ensures full automation for consistency and efficiency.

On-Site Engineering Support – With engineers stationed abroad and remote technical assistance, PURETE provides installation, training, and long-term maintenance worldwide.

Environmental Compliance – PURETE systems incorporate energy-efficient drying technologies and support eco-friendly coatings, helping manufacturers meet global standards.

Reliable Logistics and Spare Parts Supply – Ensuring that customers experience minimal downtime and consistent production capacity.

By partnering with PURETE, furniture manufacturers gain access to state-of-the-art spray coating lines that guarantee durability, efficiency, and design flexibility—all essential in today's industrial furniture market.

Conclusion

For industrial furniture manufacturers, spray painting production lines are no longer optional but essential. They provide the speed, consistency, and flexibility needed to meet growing demand for durable and stylish furniture. With applications across MDF, particle board, plywood, and solid wood, spray coating technology enables factories to scale production, reduce costs, and enhance product quality.

With its customized solutions, engineering expertise, and commitment to eco-friendly technology, PURETE stands out as the trusted partner for spray coating systems in industrial furniture manufacturing. By investing in a PURETE spray painting production line, manufacturers ensure they are prepared to meet the challenges of modern production and the expectations of global markets.

Frequently Asked Questions (FAQ)

1. What is the Difference Between Manual and Automated Spray Painting in Furniture Production?

Manual spray painting depends heavily on the operator's skill, which can lead to inconsistencies in thickness, coverage, and finish quality. Automated spray painting production lines ensure uniform application, higher speed, and reduced material waste, making them ideal for industrial-scale manufacturing.

2. Is Spray Coating Technology Suitable for MDF and Particle Board Furniture?

Yes. MDF panels and particle boards are among the most common substrates processed with automated spray coating lines. The technology ensures smooth finishes, strong adhesion, and enhanced durability, which are critical for furniture panels, cabinets, and decorative surfaces.

3. How Do Automated Spray Painting Lines Improve Efficiency?

An automated spray painting line integrates conveyors, spray booths, and robotic guns, enabling panels to be coated continuously. This eliminates downtime, reduces overspray, and allows high-volume production with consistent surface finishing.

4. Are Spray Painting Production Lines Environmentally Friendly?

Modern systems are designed with VOC filtration, energy-efficient drying systems, and support for water-based coatings, making them eco-friendly and compliant with international environmental standards. Manufacturers can reduce both emissions and operating costs.

5. What Industries Use Automated Spray Coating Systems?

Beyond furniture manufacturing, spray coating lines are widely used in interior panels, cabinetry, doors, and decorative boards. Industrial-grade systems are flexible enough to handle different coatings, finishes, and materials.

6. Why Should Furniture Manufacturers Choose PURETE Spray Coating Lines?

PURETE offers customized spray coating solutions tailored to different materials and production needs. With overseas engineers for installation and maintenance, remote technical support, and reliable logistics, PURETE ensures end-to-end service and long-term production stability for global manufacturers.