Maximizing Efficiency in Standard Roller Coating Production Lines

November 25, 2025

November 25, 2025 Hits:235second

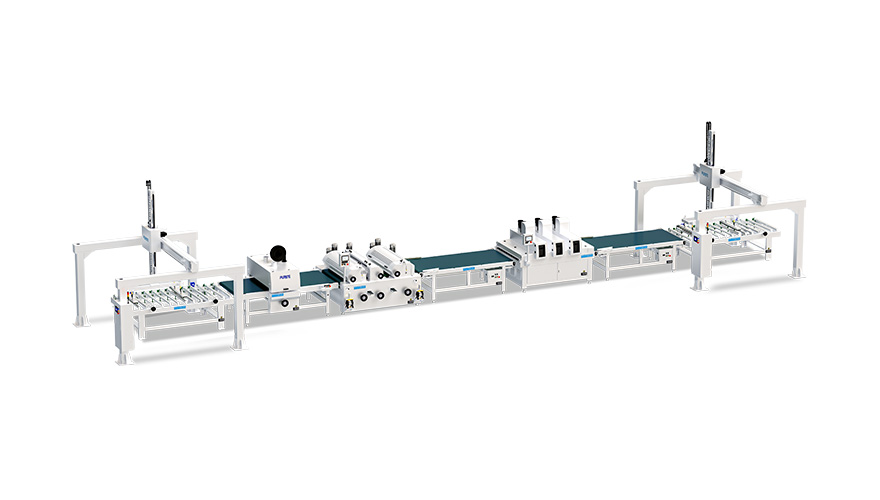

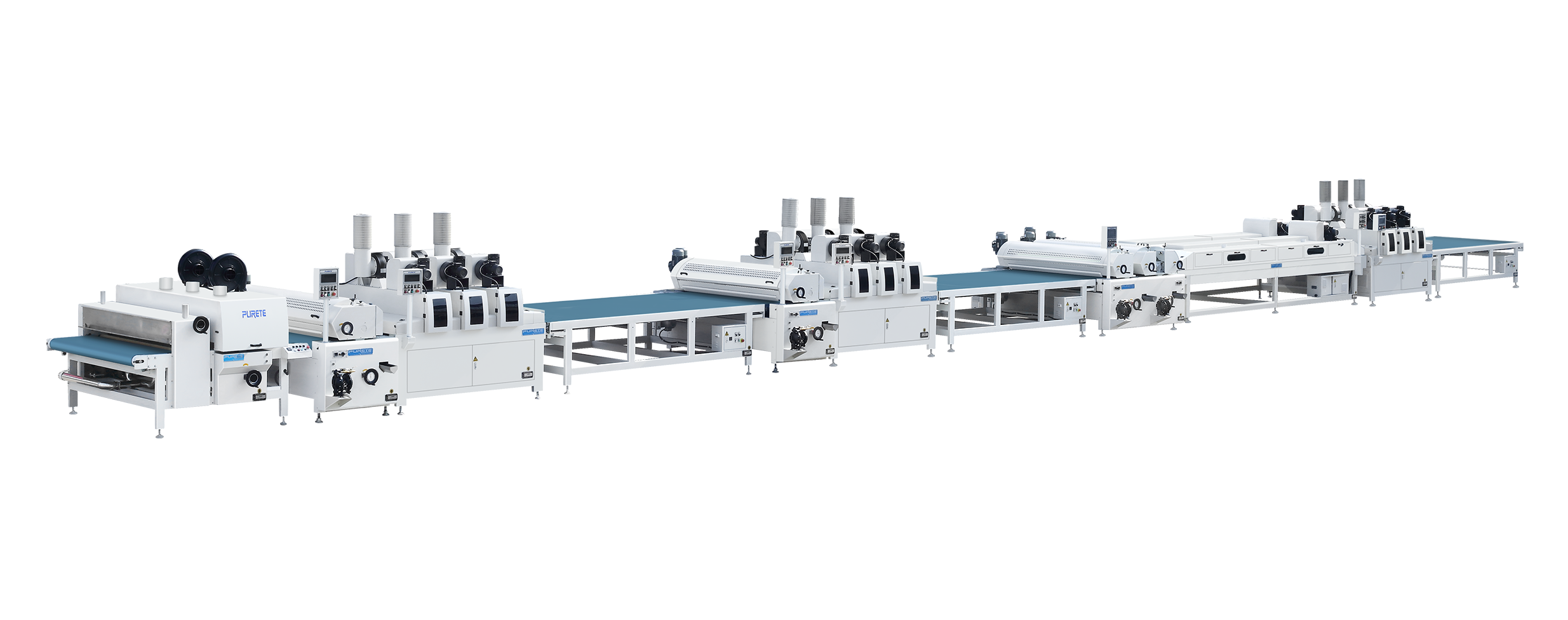

Hits:235secondThe demand for high-quality surface finishing continues to grow across the furniture, building materials, and decorative panel industries. Manufacturers require reliable, efficient, and scalable solutions to achieve consistent coating results without sacrificing production speed or increasing operational costs. Among the various types of coating technologies available, the standard roller coating production line stands out for its precision, uniformity, and suitability for high-volume manufacturing.

This article explores the capabilities of standard roller coating lines, best practices to maximize efficiency, key maintenance strategies, and the reasons why we at PURETE provide roller coating machines that help manufacturers achieve stable, repeatable, and cost-effective production outcomes.

Introduction to Standard Roller Coating Production Lines

Features and Capabilities

A standard roller coating production line is engineered to apply uniform layers of coatings such as UV coatings, primers, stains, lacquer, or water-based materials to flat surfaces. These machines use a controlled roller system to transfer coating evenly onto substrates, ensuring smooth finishes with minimal defects.

Key features include:

High-precision roller control for consistent coating thickness

Continuous high-speed processing suitable for large production volumes

Stable viscosity and material flow management

Low coating consumption compared to spray coating systems

Uniform surface appearance without streaks or uneven patches

Full-line integration with UV curing units, sanding machines, and drying tunnels

These capabilities make roller coating lines a preferred choice for surface finishing in mass production environments.

Typical Industrial Applications

Standard roller coaters are used throughout the manufacturing of:

MDF and particleboard furniture panels

Plywood and engineered wood boards

Cabinet doors and wardrobe panels

Decorative wall panels and wainscoting

Wood veneer surfaces

Flooring substrates (engineered wood, composite materials)

Interior decorative trims

Due to their speed, uniformity, and material efficiency, roller coating lines are widely implemented in automated finishing factories seeking high throughput and consistent quality.

Best Practices for Efficient Operation

To maximize productivity in a standard roller coating production line, the operational process must be optimized across multiple stages. Manufacturers who follow these best practices typically experience reduced downtime, improved coating consistency, and lower material waste.

Optimizing Coating Speed and Thickness

The most important performance indicators in roller coating are speed, thickness, and fluid behavior. Operators should continuously monitor:

1. Roller Speed and Surface Contact

Higher roller speeds reduce coating thickness

Lower speeds allow more transfer to the panel

Speed synchronization with conveyors is essential to avoid streaking

2. Roller Gap and Pressure Settings

Micro-adjustments can significantly influence film thickness

Consistent pressure prevents uneven coating distribution

Regular calibration ensures predictable coating behavior

3. Coating Viscosity and Temperature Control

Stable viscosity reduces defects such as sagging or pinholes

Automated viscosity regulation is ideal for long-duration runs

Temperature variations affect flowability and must be controlled

Combining these factors ensures reliable and uniform coating across all batches.

Reducing Waste and Downtime

High-efficiency production lines operate with minimal waste. To achieve this:

Clean panels thoroughly before coating

Dust or debris will transfer to rollers and affect results.

Use coating recovery systems

Excess material should be collected, filtered, and reused when appropriate.

Plan production runs to minimize frequent color changes

Reduces cleaning time and decreases chemical and material waste.

Implement automated monitoring systems

Alerts for viscosity, roller pressure, and pump flow reduce operator error.

Check consumables before each production shift

Worn blades, rollers, or bearings can cause unexpected downtime.

Improving production planning and monitoring reduces operational interruptions and keeps coating quality stable.

Maintenance Tips for Longevity

Regular maintenance is essential for extending the service life of standard roller coating lines and ensuring consistent performance.

Routine Inspections and Cleaning

Daily and weekly maintenance should include:

Cleaning coating rollers, applicators, and doctor blades after each run

Flushing material supply lines to prevent hardening or contamination

Checking pump filters and material tanks for buildup

Examining the surface of rollers for scratches, dents, or residue

Recording essential operating data to detect anomalies

These steps ensure that coating quality remains stable and reduce the probability of unexpected failures.

Spare Parts and Component Care

Key components requiring regular attention include:

Rubber and steel application rollers

Bearings and drive components

Conveyor belts

Doctor blades

Viscosity control equipment

Servo motors and speed-regulation systems

Preventive maintenance should include:

Scheduled replacement of wear parts

Proper lubrication for moving mechanical parts

Monitoring temperature and load of motors

Ensuring stable power supply and electrical safety

Factories with clear maintenance procedures benefit from reduced repair costs and improved long-term performance.

Why PURETE Roller Coating Machines Deliver Consistent Quality

When it comes to selecting a roller coating machine, many manufacturers prioritize precision, stability, and adaptability. At PURETE, we design and manufacture roller coating equipment with these priorities in mind. Our goal is to provide machines that support long-term production, reduce coating waste, and maintain consistent surface finishing quality.

1. Precision Engineering and Stable Coating Performance

Our roller coaters use:

Fine-adjustment mechanisms

Servo-driven roller control

Integrated speed synchronization

Optimized roller structures

These features help maintain uniform coating thickness even when running at high production speeds.

2. Low Coating Consumption and Efficient Material Transfer

We prioritize energy efficiency and material savings. Our machines:

Reduce coating waste through intelligent material distribution

Optimize roller contact for smooth transfer

Support stable flow systems for continuous, long-run production

This allows manufacturers to lower operating costs without compromising quality.

3. Durable Build Quality for Heavy-Duty Production

Our equipment is built for industrial environments, using reliable components and robust frames to support long-term operation in 24-hour production lines.

4. Flexible Line Integration

PURETE roller coating machines can be integrated with:

UV curing systems

Drying tunnels

Sanding and brushing units

Cleaning and dust removal modules

This flexibility helps manufacturers create full-solution coating lines suitable for wood panels, furniture boards, and other flat-surface materials.

Conclusion

A standard roller coating production line is one of the most efficient solutions in modern surface finishing. Its ability to deliver uniform, high-quality coatings at high production speeds makes it essential for panel manufacturers, furniture producers, and decorative surface material suppliers.

By optimizing coating parameters, reducing waste, and following proper maintenance procedures, factories can significantly enhance operational efficiency and extend equipment lifespan. And for manufacturers seeking a reliable, precise, and durable solution, our roller coating machines at PURETE provide the stability, accuracy, and long-term value required for advanced industrial production.