How UV Roller Coating Machines Ensure High-Quality Finishes

November 19, 2025

November 19, 2025 Hits:272second

Hits:272secondIn modern furniture manufacturing, interior panel production, and decorative surface finishing, UV roller coating machines play a crucial role in achieving flawless, durable, and visually appealing surfaces. Industries that work with MDF boards, particle boards, PVC panels, wood veneer, SPC floors, WPC boards, and high-gloss decorative materials now rely heavily on UV coating technology to ensure consistent finishing quality, fast curing, and enhanced product durability.

As global demand grows for high-quality surface finishing equipment, UV roller coating lines have become essential across large-scale manufacturing facilities. Designed to deliver uniform coatings using rollers and instantly cure the applied layer with ultraviolet light, these machines help businesses increase productivity while reducing labor and energy consumption.

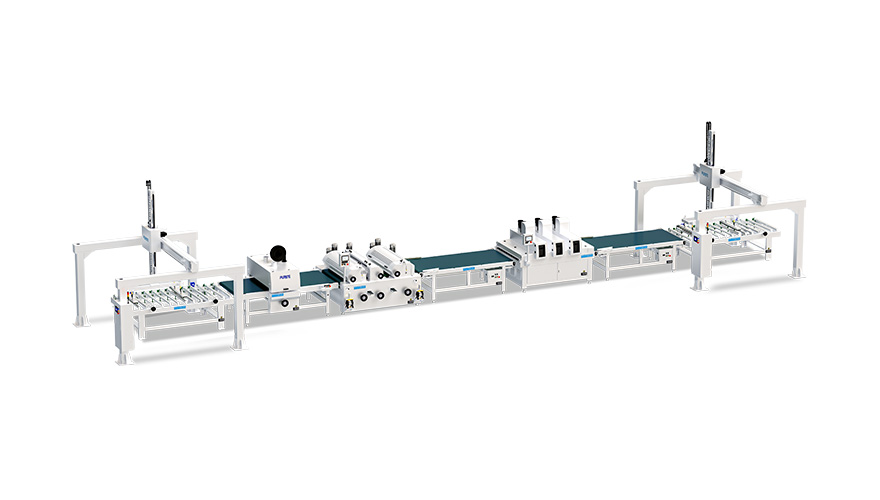

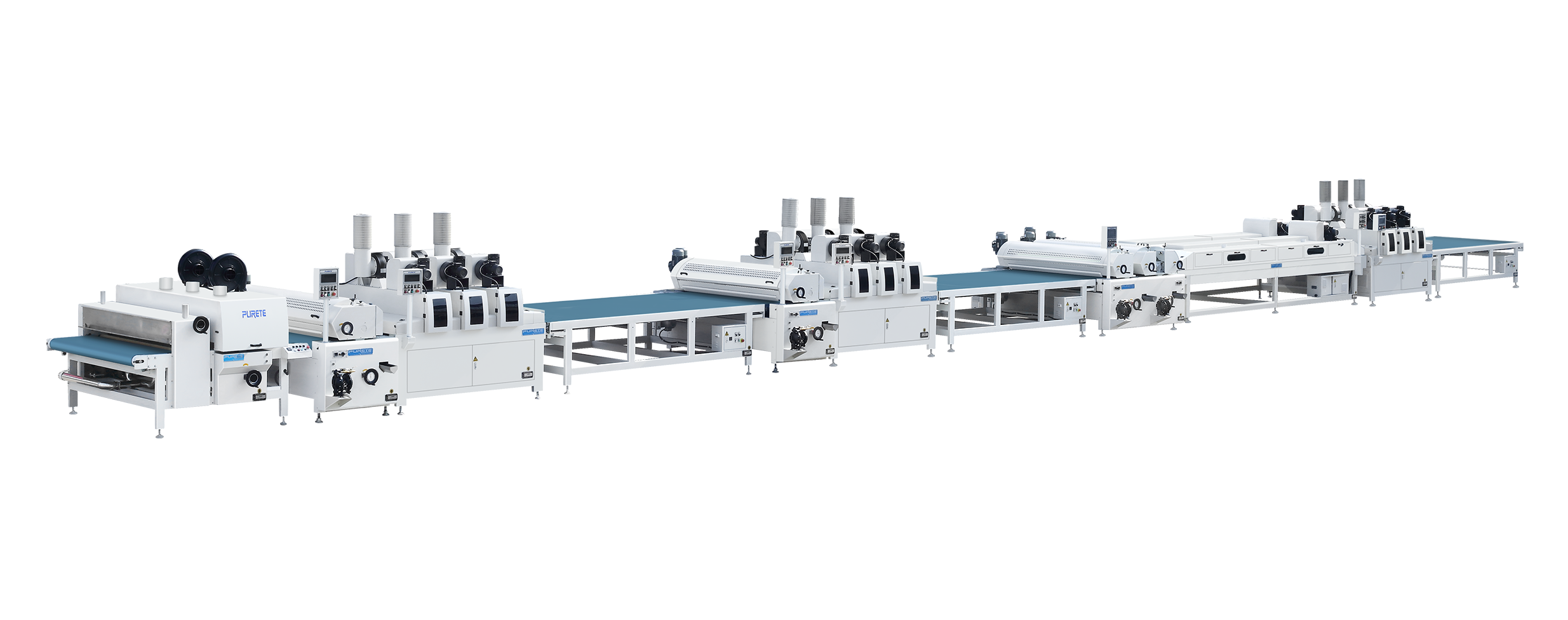

This article explains how UV roller coating technology works, its advantages, key applications, and what to consider when choosing a UV roller coating production line. It will also show why many manufacturers prefer established brands such as PURETE, known in the industry for professional finishing solutions and reliable full-line production systems.

Overview of UV Roller Coating Technology

UV roller coating technology is a finishing method that uses a combination of precision rollers and ultraviolet curing systems to apply liquid coatings onto flat panels with high consistency. Compared with traditional spraying or brushing, roller coating offers:

Extremely uniform coating thickness

Reduced coating waste

Cleaner production process

Higher line speed and productivity

Superior surface quality and gloss control

After the coating is applied, specially designed UV curing lamps trigger an immediate chemical reaction that hardens the coating within seconds. This instant-curing capability allows manufacturers to move products to the next production stage without long drying times.

Because of the high efficiency and precision of roller coating machines, the technology has become widely used in furniture manufacturing, decorative panel production, flooring factories, and door manufacturing lines, where high-volume output and quality consistency are critical.

What is a UV Roller Coating Machine?

A UV roller coating machine is an industrial finishing system designed to apply UV-curable coating onto board surfaces through a set of rollers. The machine typically includes:

Feeding conveyor

Metering roller and application roller system

Coating tank

UV curing section

Optional dust removal or brushing modules

Control system for coating thickness adjustment

This technology is suitable for applying:

UV primer

UV topcoat

High-gloss coatings

Matt coatings

Anti-scratch coatings

UV sealer layers

UV roller coaters handle a wide range of panel materials, including:

MDF and HDF boards

Plywood

Solid wood panels

SPC/WPC flooring

PVC decorative panels

Wood veneer sheets

Acrylic panels

Because of its versatility and consistent performance, companies across the woodworking and decorative material sectors integrate UV roller coating lines into their production for efficient, stable, and repeatable finishing results.

Applications in Industrial Production

UV roller coating lines are used across many industries that require high levels of surface durability, scratch resistance, gloss control, and decorative quality. Key sectors include:

1. Furniture Manufacturing

UV roller coaters are widely used for:

Cabinet doors

Wardrobe panels

Tabletop panels

Bookshelves and wall décor panels

The uniformity and curing speed make UV coating ideal for mass production.

2. Interior Decoration Panels

Manufacturers of interior wall panels, decorative surfaces, and PVC laminated boards rely on UV coating to achieve higher gloss, better color consistency, and scratch resistance.

3. Flooring Production

SPC/WPC and engineered wood flooring often require:

UV primer

Wear-resistant UV coatings

Topcoat layers

Roller application ensures precision thickness and excellent abrasion resistance.

4. Doors and Building Materials

Interior doors, composite doors, and veneered architectural panels use UV coating to achieve smoothness and long-lasting surface aesthetics.

5. High-Gloss and Super Matte Finishing

The demand for high-gloss furniture and ultra-matte surfaces makes UV coating systems important in premium product manufacturing lines.

6. Electronics and Packaging Materials

Certain electronics casings, rigid packaging substrates, and protective panels also use UV coatings for enhanced durability.

This wide range of applications shows why UV roller coating lines are now considered essential equipment for factories that aim to deliver consistent, market-competitive products.

Key Advantages of UV Roller Coating Lines

1. High Precision and Uniform Coating

One of the biggest strengths of UV roller coating technology is its ability to deliver exceptionally uniform coating layers. Compared with spray finishing systems, roller coating provides:

Minimal coating deviation across the panel

Accurate thickness control through metering rollers

Smooth, defect-free surfaces

No overspray or coating waste

This precision ensures that every panel meets the same quality standard, making the technique ideal for large-volume OEM and ODM production lines.

2. Fast Curing and High Production Efficiency

UV curing is one of the fastest curing technologies in industrial finishing. Within seconds of passing through the UV lamp, the coating becomes:

Fully hardened

Ready for sanding, stacking, or packaging

Resistant to scratches and chemicals

This instant-curing capability dramatically shortens production cycles, allowing manufacturers to:

Increase line speeds

Reduce production bottlenecks

Scale up output without expanding factory size

UV roller coating lines thus contribute directly to higher operational efficiency and shorter lead times, which are essential for competitive manufacturing.

3. Energy Saving and Cost Efficiency

Many factories choose UV roller coating systems for the significant cost savings they bring:

UV curing consumes less energy than long-duration thermal drying

Roller coating reduces coating material waste

Automated systems reduce labor dependency

High-speed production lowers per-unit finishing costs

In long-term industrial use, these advantages translate into lower operational expenses and improved profit margins.

Factors to Consider When Choosing a Roller Coating Production Line

Selecting a UV roller coating line is an important investment decision. To ensure long-term performance, manufacturers should consider the following key factors:

1. Machine Specifications and Capabilities

Before purchasing, evaluate whether the machine supports:

Required panel width and thickness

Desired coating types (UV primer, topcoat, matt coat, high gloss)

Optional modules (dust removal, curtain coating, sanding units, double roller application, cleaning units)

Line speed and curing efficiency

Compatibility with existing production lines

High-end brands typically offer modular options, allowing factories to build a complete UV coating production line, such as:

Roll coater

Curtain coater

UV dryer

Dust cleaning machine

Conveyor systems

When selecting equipment, it is essential to choose a manufacturer with stable technology and proven industry experience.

2. Maintenance and Longevity

A reliable UV roller coating machine should offer:

Easy roller adjustment

Simple cleaning structure

Durable rollers and mechanical parts

Stable PLC control systems

Long-life UV lamps and energy-efficient designs

Choosing a well-established and reputable supplier ensures that the equipment will maintain performance across years of continuous production.

This is why many buyers prefer professional brands like PURETE, known for its advanced surface finishing equipment, reliable production lines, and long-term after-sales support. PURETE has built a strong reputation in the woodworking and decorative panel industries, offering complete coating line solutions that meet international production standards.

Their systems are widely recognized for stability, automation, and smooth integration into high-volume production environments—making them a trusted partner for manufacturers looking for both performance and durability.

Conclusion

UV roller coating machines are essential in today's industrial finishing landscape, especially for manufacturers requiring high-precision, durable, and aesthetically superior surfaces. The ability to apply consistent coatings, cure instantly, reduce waste, and increase production efficiency makes UV roller coating lines a core component of modern panel and furniture production.

When selecting a UV roller coating production line, factors such as machine specifications, automation level, energy consumption, stability, and maintenance requirements must be carefully considered. Working with reputable suppliers—such as PURETE, a well-known brand with strong expertise in surface treatment and coating line solutions—ensures long-term reliability and professional technical support.

As demand for high-quality surfaces continues to rise globally, UV roller coating technology will remain one of the most efficient and cost-effective finishing solutions for manufacturers seeking to enhance product quality and stay competitive in the industry.