UV Roller Coating Machines: The Key to Fast, Consistent, and Durable Furniture Finishing

December 18, 2025

December 18, 2025 Hits:202second

Hits:202secondIn industrial furniture manufacturing, surface finishing is no longer just about appearance—it directly impacts production efficiency, product durability, and overall manufacturing cost. As furniture factories scale up for mass production and OEM supply, finishing processes must deliver consistent quality while keeping pace with high-volume output.

While spray coating remains important for complex shapes, it is not always the most efficient solution for flat or semi-flat components commonly used in panel-based furniture. Uneven film thickness, longer drying times, and higher material loss can become limiting factors in large-scale production environments.

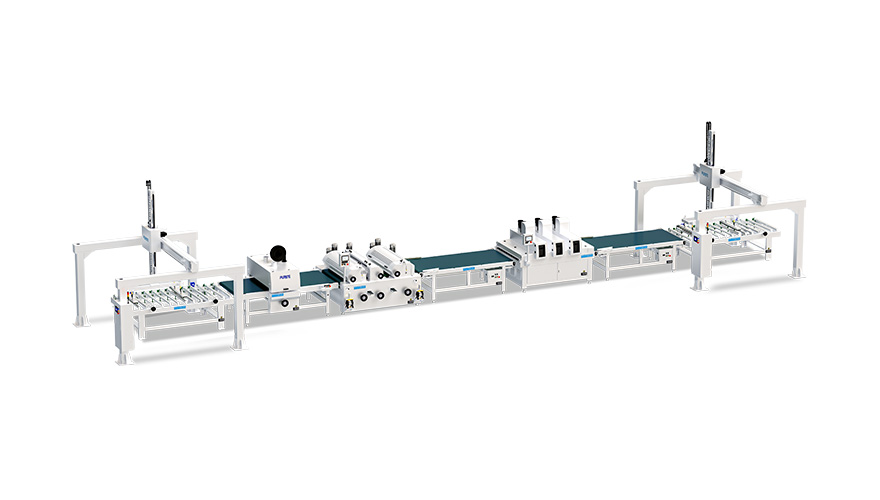

This is why UV roller coating machines continue to play a critical role in modern furniture factories. By combining precision roller coating systems with fast UV curing technology, manufacturers can achieve uniform finishes, rapid throughput, and durable surface protection—making UV roller coating a foundational process in automated furniture finishing lines.

What Is a UV Roller Coating Machine?

A UV roller coating machine is an industrial surface finishing system designed to apply liquid coatings—such as UV lacquer, primer, or topcoat—onto flat or slightly profiled surfaces using roller-based application, followed by instant curing through ultraviolet light.

Unlike spray coating, which disperses coating material into the air, roller coating transfers the coating directly from the roller to the substrate. This direct contact allows for highly controlled film thickness and excellent material utilization.

A typical UV roller coating system includes:

Application and metering rollers

Conveyor-based feeding system

UV curing units

Centralized control for speed and coating parameters

These machines are widely used in furniture panel coating, wood-based panel finishing, and automated coating lines where efficiency and repeatability are essential.

Advantages of UV Roller Coating

Fast Curing & High Throughput

UV curing technology enables coatings to harden almost instantly once exposed to ultraviolet light. This eliminates long drying times and allows continuous production flow.

For furniture factories, this means:

Higher line speed

Shorter production cycles

Immediate stacking or downstream processing

In mass production environments, fast curing directly translates into higher daily output and better utilization of factory space.

Highly Uniform Coating

Roller coating machines are particularly effective at producing highly uniform coating thickness across large surfaces. Film thickness is controlled mechanically through roller gaps and synchronized speed settings.

This level of control ensures:

Consistent surface appearance

Reduced rework due to coating defects

Stable quality across large batches

Uniformity is critical for OEM furniture production, where consistency across thousands of panels is a basic requirement.

Lower VOC Emissions

UV coatings typically contain lower VOC content compared to many traditional solvent-based finishes. When combined with roller coating's efficient material transfer, this results in cleaner and more controlled production conditions.

Benefits include:

Reduced emissions in factory environments

Improved operator safety

Easier compliance with environmental standards

This makes UV roller coating suitable for manufacturers upgrading toward more sustainable production practices.

Why Furniture Manufacturers Still Rely on Roller Coating

Despite the rise of robotic spraying and digital finishing technologies, roller coating remains a core process in furniture manufacturing—especially for flat-panel components.

Manufacturers continue to rely on roller coating because it offers:

Exceptional stability for long production runs

Predictable coating performance

High material utilization

Low variation between batches

For industrial-scale furniture production, roller coating provides a level of reliability that is difficult to match with spray-only solutions.

Applications in Furniture Manufacturing

Flooring

In flooring production, UV roller coating is widely used to apply wear-resistant topcoats. The combination of uniform coating and UV curing ensures durable surfaces suitable for high-traffic environments.

Panel Furniture

Panel furniture components such as shelves, side panels, and tabletops benefit from roller coating's ability to cover large surfaces evenly, making it ideal for flat panel finishing.

Cabinets & Doors

Cabinet doors and flat door panels require smooth, durable finishes. UV roller coating machines provide consistent results for kitchen cabinets, wardrobes, and storage furniture.

Wood Mouldings

For wood mouldings with simple profiles, roller coating offers efficient and repeatable surface treatment, supporting stable quality in continuous production lines.

Technological Enhancements in Modern UV Roller Coating Machines

Modern UV roller coating machines have evolved to meet the demands of automated furniture production lines.

Key advancements include:

Improved roller materials for better coating transfer

Precision control of coating thickness and speed

Optimized UV lamp systems for consistent curing

Integration with upstream and downstream equipment

These enhancements allow manufacturers to build highly automated coating lines with predictable performance and minimal downtime.

PURETE's Strength in UV Roller Coating Production Lines

At PURETE, we design UV roller coating production lines specifically for industrial furniture manufacturing and mass production environments.

Highly Stable Machines for 24/7 Output

Our UV roller coating machines are built to support continuous operation, helping factories maintain stable output across long shifts and high-volume orders.

Modular Configuration for Different Surface Requirements

PURETE production lines can be configured with multiple coating stages, roller combinations, and curing setups to match different furniture surfaces and finishing requirements.

Trusted by Numerous Wood Industry Manufacturers

Our solutions are widely used across panel processing, furniture component manufacturing, and OEM production lines, supporting consistent quality at factory scale.

By focusing on production-line stability and practical engineering, PURETE helps manufacturers achieve reliable, repeatable, and scalable furniture finishing.

Conclusion

UV roller coating machines remain a key technology in modern furniture manufacturing, particularly for flat and panel-based products. With fast UV curing, uniform coating application, and high production efficiency, roller coating supports the demands of industrial-scale and OEM furniture production.

With advanced UV roller coating production lines from PURETE, furniture manufacturers can improve finishing consistency, increase throughput, and build stable coating systems suited for long-term mass production.