Why Roller Coating Lines Are Ideal for MDF Finishing?

July 17, 2025

July 17, 2025 Hits:712second

Hits:712secondIn today's fast-paced manufacturing landscape, MDF finishing has become a critical step in the production of furniture panels, cabinet doors, decorative wall boards, and more. As demand grows for surfaces that are uniform, durable, and visually appealing, manufacturers are turning to roller coating lines to achieve high-quality results at industrial speeds. This article explores the working principles of roller coating technology, its suitability for MDF surfaces, key advantages, typical applications, and how PURETE supports scalable, automated, and eco-friendly MDF coating.

An Overview of Roller Coating Technology and Its Working Principles

Roller coating is a mechanical process that uses rollers to apply a uniform layer of coating—such as UV coatings, PU coatings, or water-based lacquers—to flat substrates like MDF boards. A standard roller coating line typically includes:

A dust removal system to clean the substrate

A metering roller to control the amount of coating

A coating roller to transfer the material to the MDF surface

IR or UV curing ovens to dry or cure the applied layer

A PLC-controlled automation system for precision and consistency

Unlike spray coating, which involves atomizing coating into fine particles, roller coating relies on direct contact. This ensures accurate coating thickness, less overspray, and better transfer efficiency, which is especially important in large-volume production environments.

Why Roller Coating Is Particularly Effective for Flat MDF Surfaces

MDF (Medium Density Fiberboard) is engineered to be smooth, uniform, and dimensionally stable—three attributes that make it highly compatible with roller coating machines. Here's why:

Flatness and uniform density: These allow for full contact between the coating roller and substrate, ensuring an even film layer.

No wood grain or surface variation: MDF's lack of texture means coating uniformity is easier to achieve compared to natural wood.

Excellent adhesion: MDF readily accepts coatings, especially UV-curable and water-based formulations, without the risk of penetration irregularities.

Efficient edge coating: With optional configurations, roller coating lines can also apply coating to the edges of MDF panels in a single pass.

For industries requiring consistent visual appearance—such as furniture, cabinetry, or wall panel production—this high compatibility leads to significant reductions in defects and material waste.

Advantages of Roller Coating

1. Superior Coating Uniformity

The metering roller allows for precise control over coating thickness, down to the micron level. This results in consistent gloss, color tone, and texture across all panels.

2. High-Speed Productivity

A modern roller coating line can operate at speeds ranging from 5 to 70 m/min. This enables mass production of MDF components with minimal downtime and high repeatability.

3. Reduced Coating Waste

Unlike spray coating, roller coating applies material only where needed. This minimizes overspray and reduces coating usage by up to 30%, leading to lower raw material costs.

4. Environmentally Friendly

Roller systems are ideal for low-VOC and water-based coatings. Their enclosed setup and efficient application reduce air pollution, improve worker safety, and simplify compliance with environmental standards.

5. Lower Operating Costs

Roller coating requires less ventilation, fewer filters, and minimal masking, which translates into reduced labor, energy, and maintenance costs.

6. Flexible Finish Options

Roller coaters support a wide range of finishes, from high-gloss UV coatings to matte or soft-touch finishes. This versatility allows manufacturers to meet changing market demands without reconfiguring their entire production line.

7. Ease of Automation and Integration

Thanks to programmable PLC controls and modular components, roller coating lines can be fully integrated with automated feeding systems, vision inspection, and robotic stacking—ideal for Industry 4.0 environments.

Common Applications of Roller Coating Machines

Roller coating machines are used widely in MDF-based and other flat-panel manufacturing. Typical applications include:

Furniture boards: Coating flat MDF panels for wardrobes, desks, shelves, and kitchen cabinets

Cabinet doors: Applying decorative and protective coatings to MDF doors

Decorative wall and ceiling panels: Ensuring consistent appearance for architectural interiors

Flooring boards (SPC, WPC, LVT): Adding UV wear layers to pre-printed designs

Edge-banding systems: Coating the edges of panels with the same finish as the surface

Plywood or veneered panels: Applying topcoats to wood veneer surfaces bonded to MDF

In all these applications, roller coating delivers precision, reliability, and efficiency unmatched by traditional spray methods.

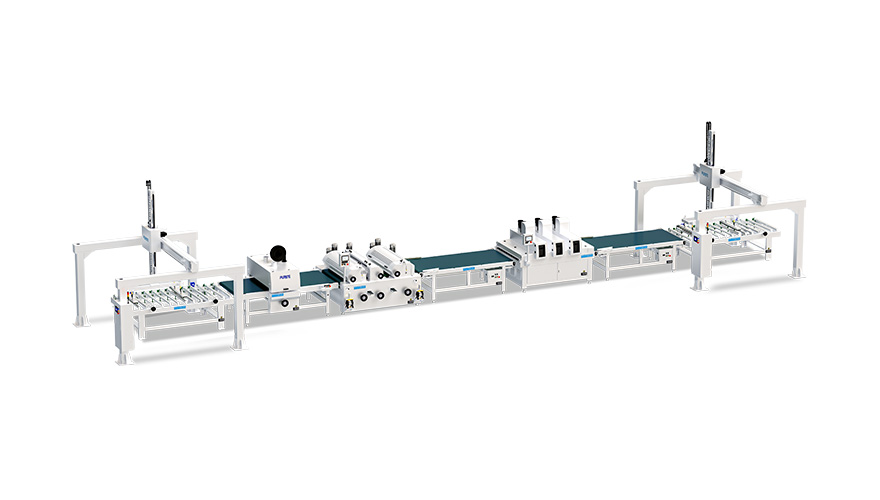

How PURETE's Roller Coating Solutions Help Manufacturers Achieve Scalable Quality

PURETE is a trusted production line manufacturer specializing in automated coating systems designed for MDF and flat panel applications. We provide complete roller coating solutions tailored for production lines requiring fast changeover, high speed, and surface consistency.

Our machines are known for:

Precision control: Using servo-driven metering rollers and automatic gap adjustment to ensure even coating film

High-speed operation: Lines capable of up to 70 m/min, suitable for large-format and high-volume production

Advanced curing options: Integration with IR preheating and UV curing ovens for both water-based and UV coatings

Edge coating integration: Coating units capable of treating edges during the same production pass

Modular design: Custom configurations that suit different plant layouts and MDF board formats

Automation readiness: Equipped with touchscreen PLCs, auto-cleaning rollers, and inline inspection systems

PURETE's systems are in use across over 80 countries, enabling manufacturers to achieve better finish uniformity, material efficiency, and production stability.

Conclusion

Roller coating technology is the optimal choice for MDF surface finishing, especially in industries that value precision, speed, eco-compliance, and cost-effectiveness. Its compatibility with MDF's flat structure ensures minimal defects and consistent appearance, while its material efficiency and automation capability support large-scale operations.

PURETE's roller coating lines offer an advanced, scalable solution for manufacturers looking to upgrade their MDF finishing capabilities. With robust engineering, proven reliability, and flexible configurations, PURETE helps manufacturers reduce waste, enhance surface quality, and increase throughput—all while staying ahead in a competitive market.