What Is a Wrapping Production Line and How Does It Work?

June 18, 2025

June 18, 2025 Hits:675second

Hits:675secondIn the modern manufacturing and logistics landscape, wrapping production lines have become essential for businesses seeking efficiency, product protection, and scalable growth. These systems automate the packaging process, ensuring products are securely wrapped and ready for distribution or sale. Understanding the structure, operation, and benefits of wrapping production lines is critical for any company aiming to enhance its packaging strategy and maintain a competitive edge.

What Is a Wrapping Production Line?

A wrapping production line is an integrated assembly of machines and processes designed to automatically wrap products or packages with materials like plastic film, paper, or foil. The primary purpose is to protect goods, improve their appearance, and prepare them for transport or retail display. These lines can range from semi-automatic setups for smaller operations to fully automated systems capable of handling high-volume production.

Wrapping production lines are widely used in industries such as food and beverage, pharmaceuticals, electronics, automotive, and consumer goods. Their flexibility allows them to accommodate a variety of product shapes, sizes, and packaging requirements, making them a cornerstone of modern packaging operations.

Key Components of a Wrapping Production Line

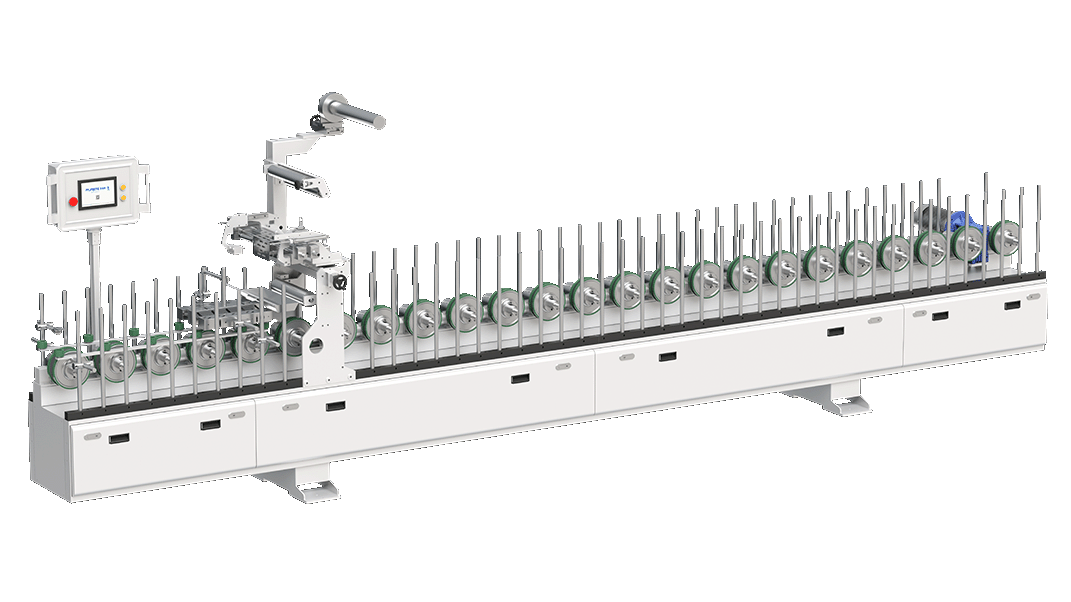

A wrapping production line is composed of several precisely engineered components that work together to ensure stable, accurate, and efficient wrapping performance. Based on the provided diagram, here are the key components:

1. Drive Wheel

The drive wheels are responsible for transmitting power and guiding the movement of the product along the line. This system utilizes a rapid adjustment mechanism, allowing for quick and flexible changes to accommodate various product sizes and speeds.

2. Vertical Columns

These vertical support rods ensure structural integrity and alignment across the machine frame. They provide a stable mounting base for rollers and transmission components, contributing to high precision during operation.

3. Material Rack Assembly

The material rack holds and feeds the wrapping material (film or tape) into the machine. Its modular design ensures easy replacement and compatibility with different material types and roll sizes.

4. Slitting Cutter

This cutter ensures clean and accurate cutting of the wrapping material, allowing for precise application and reducing waste. Its positioning also supports fast-change functionality.

5. Swing Control Box

The swing-mounted control box houses the electrical interface and touch panel for the machine’s operations. Its flexible position allows operators to monitor and adjust parameters conveniently during production.

6. Front Feed Rollers

These rollers push products forward along the conveyor system. The front feed rollers are designed with single-top bearings and rotate independently in a single direction, which improves material feeding stability and precision.

7. Machine Frame

The machine frame is fully welded and features a rigid structural design. The reducer gearboxes are mounted onto pre-drilled flat holes on the gantry, ensuring stability, vibration reduction, and long-term reliability during high-speed operation.

How Does a Wrapping Production Line Work?

The operation of a wrapping production line follows a streamlined, step-by-step process designed for high efficiency and minimal human intervention:

Product Loading: Items are fed onto the infeed conveyor manually or automatically.

Alignment and Spacing: Sensors and guides ensure each product is correctly positioned.

Wrapping: Depending on the system, film is applied by rotating around the product (stretch), pulling over it (shrink), or enclosing it horizontally (flow wrap).

Sealing and Cutting: The film is sealed tightly and cut to separate individual units.

Discharge: The wrapped products exit the system, ready for the next stage.

The entire process can be fine-tuned for different product sizes, film types, and throughput rates, making it highly adaptable.

Benefits of Using a Wrapping Production Line

Implementing a wrapping production line offers several significant advantages:

Enhanced Efficiency: Automation accelerates the packaging process, enabling high-volume output and reducing production bottlenecks.

Consistent Quality: Machines deliver uniform wrapping and sealing, ensuring every package meets strict quality standards.

Cost Reduction: Lower labor requirements and optimized material usage translate into significant cost savings. Automated systems also minimize waste by using only the necessary amount of wrapping material.

Improved Product Protection: Proper wrapping shields products from dust, moisture, and physical damage during storage and transport.

Better Presentation: Professionally wrapped products look more appealing, enhancing brand image and increasing consumer confidence.

Operational Flexibility: Modern systems can handle a wide range of product types and packaging materials, making them suitable for diverse manufacturing needs.

Reduced Downtime: Automated error detection and easy maintenance features help keep the line running smoothly, maximizing productivity.

Common Applications in Different Industries

Wrapping production lines are widely used across various industries to enhance efficiency and product quality. Here are the main application areas:

Paint-Free Doors: Wrapping production lines are used to produce components such as door casings (boards), door panels, and door frames. These systems ensure a seamless and high-quality finish, which is essential for modern interior doors.

Doors and Windows: The technology is applied to the manufacturing of sliding door frames, push-pull doors, and all-aluminum cabinets. Wrapping lines help achieve precise and durable surface treatments, improving both appearance and longevity.

Wall Decoration: In the field of wall decoration, wrapping production lines are used for processing skirting boards, ceiling lines, waistlines, and decorative strips. This enables mass production of consistent, aesthetically pleasing, and functional decorative elements for interior spaces.

These applications demonstrate the versatility of wrapping production lines in supporting the manufacturing of doors, windows, and decorative building materials, meeting the diverse needs of the construction and interior design industries.

Choosing the Right Wrapping Production Line

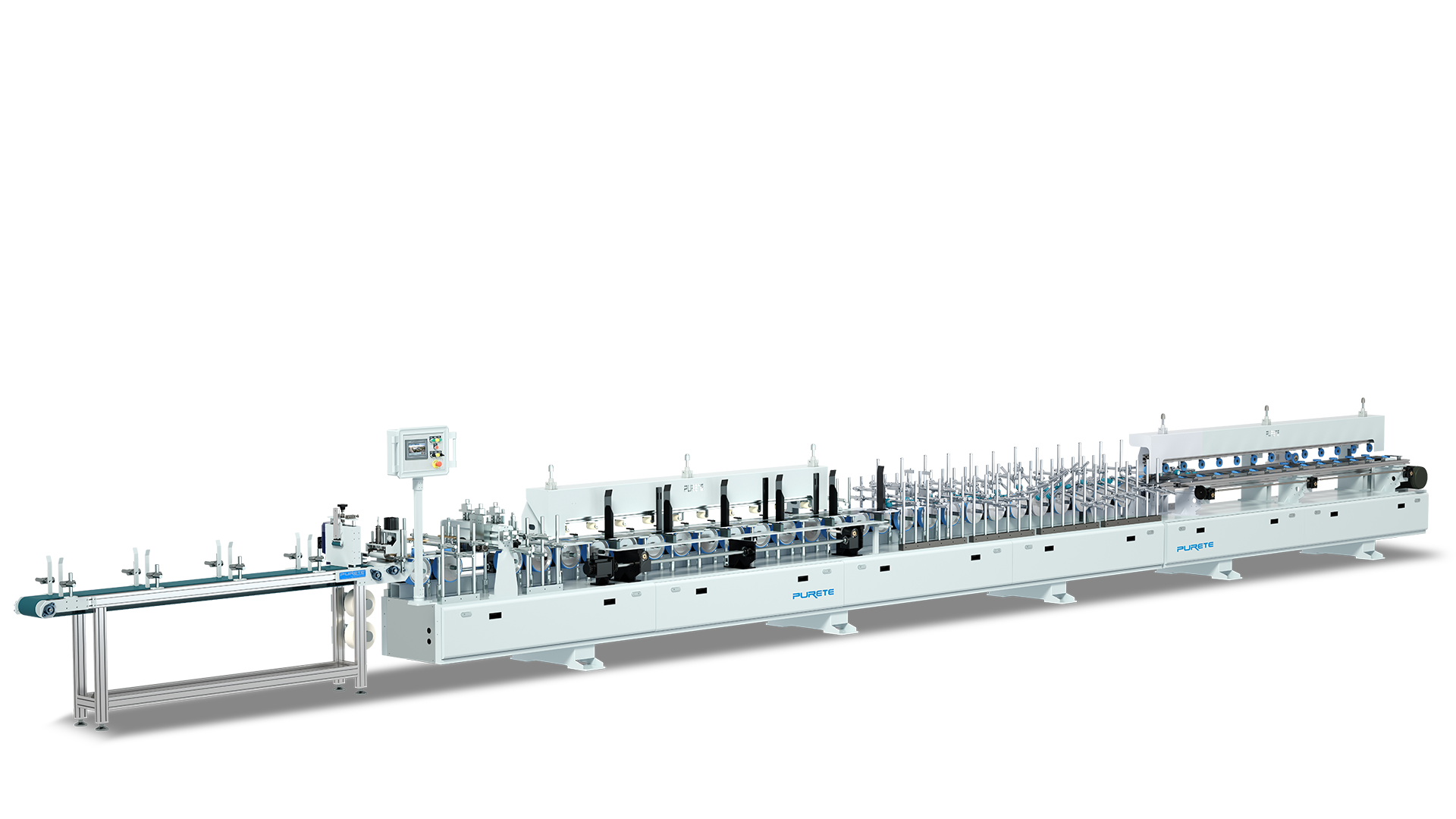

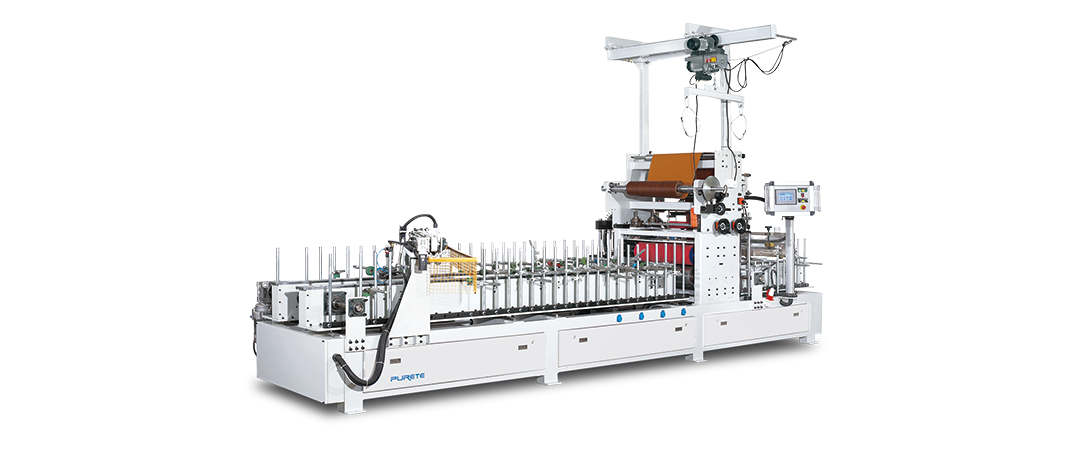

Selecting the right wrapping production line depends on the product type, size, and production volume. PURETE, a trusted name in surface decoration equipment, offers a comprehensive range of machines to meet various customer needs:

BF-33/45-L Profile Wrapping Machine: Ideal for narrow profiles like trim strips, skirting boards, and door edges. It provides high-speed, precision wrapping for linear materials.

BF-66/126-L Wide Panel Wrapping Machine: Designed for larger surfaces such as aluminum cabinets and flat door panels. It delivers stable and efficient coverage for wide boards.

Corner Wrapping Line: Perfect for products that require folded corner finishes, ensuring seamless application along edges.

Side Gluing Machine: Supports production lines that need multi-part bonding before or after wrapping, improving workflow efficiency.

PURETE wrapping machines are well-suited for working with various materials, including hardware parts, aluminum profiles, MDF, and decorative panels. Their strong structural design, reliable components, and user-friendly interfaces make them a popular choice for manufacturers aiming for top-quality finishes.

Conclusion

A wrapping production line is a vital asset for any business involved in surface decoration and protection. From door frames to baseboards and aluminum windows, these machines help manufacturers deliver high-quality, visually appealing products with efficiency and precision. With versatile solutions like those from PURETE, companies can meet diverse production demands while maintaining consistent excellence in every finished piece.