How Does the PUR Laminating Machine Process Differ from Other Laminating Methods?

April 03, 2025

April 03, 2025 Hits:1737second

Hits:1737secondLaminating technology plays a crucial role in modern industries such as packaging, furniture, automotive, printing, and electronics. It improves the durability, appearance, and functionality of materials by bonding multiple layers together.

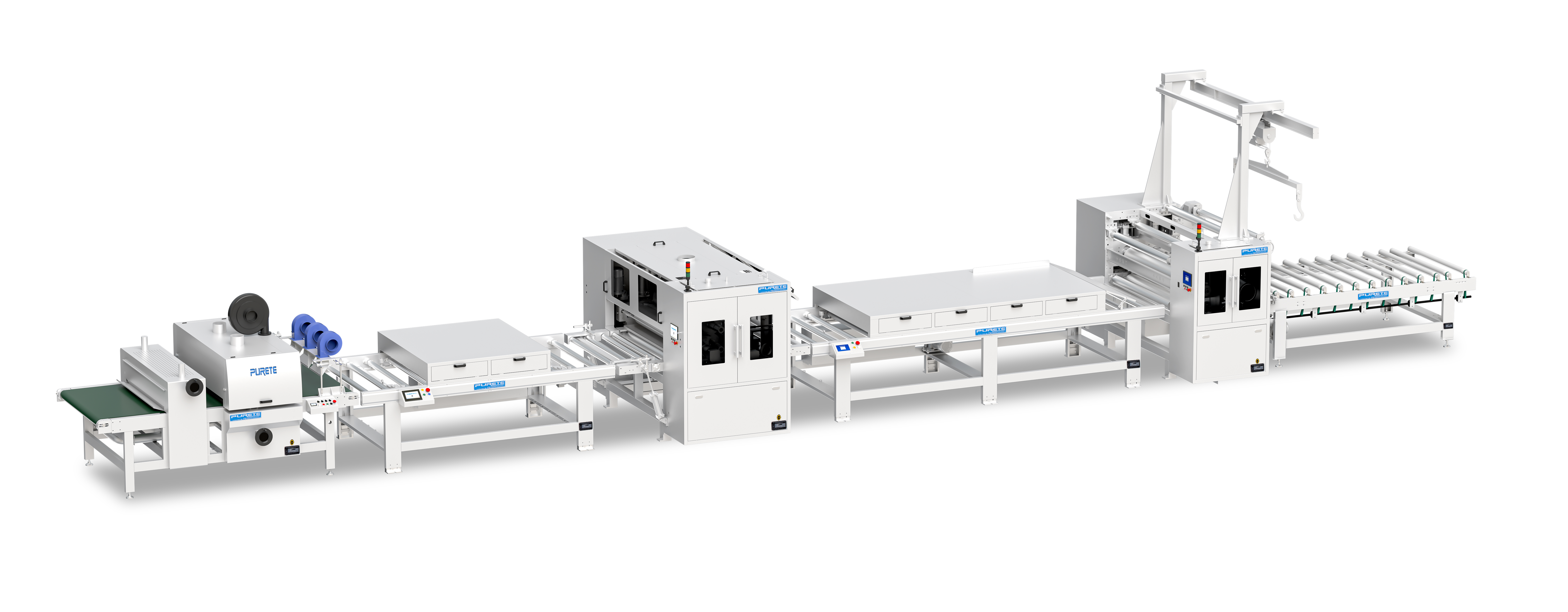

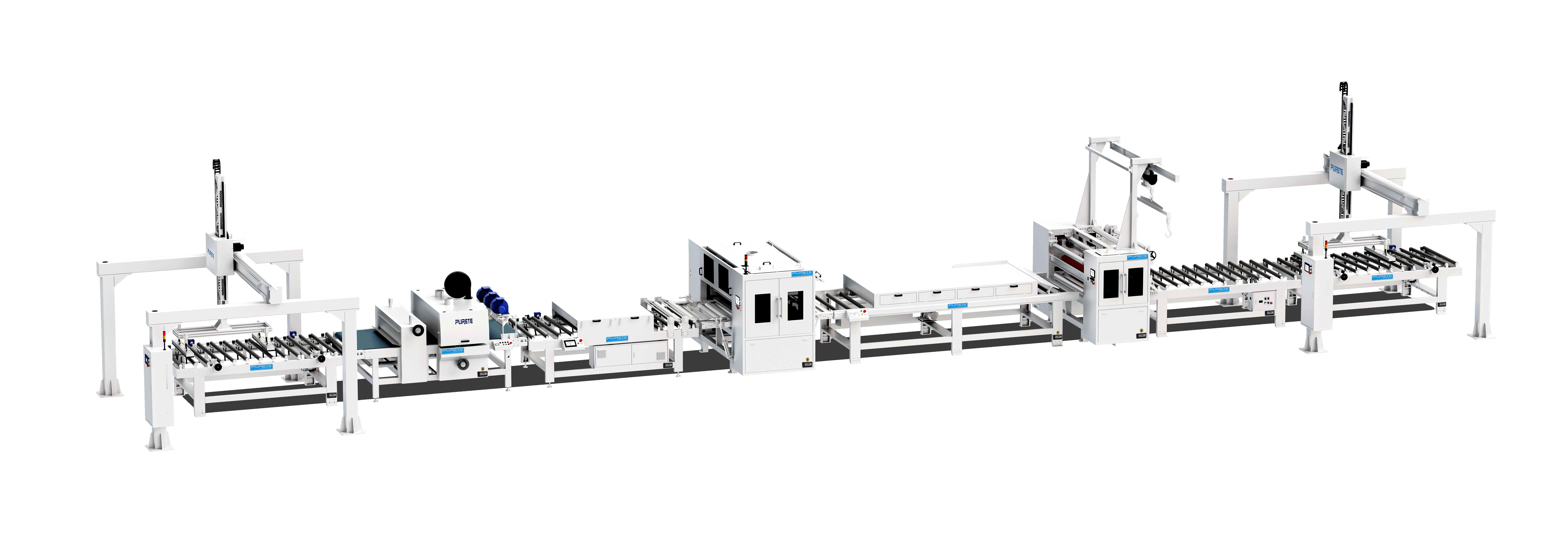

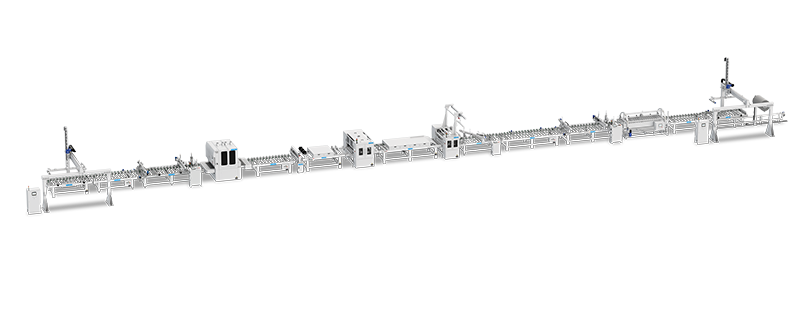

Among the available methods, the PUR laminating machine (Polyurethane Reactive laminator) stands out due to its strong adhesive bonding, resistance to moisture and heat, and versatile material compatibility. This article explores how the PUR lamination process differs from hot melt, solvent-based, water-based, and film lamination, while highlighting its key advantages for industrial laminating lines.

Understanding PUR Laminating Technology

A PUR lamination machine uses polyurethane-based reactive adhesives (PUR adhesives). These adhesives cure through a chemical reaction with ambient moisture, creating a cross-linked, permanent bond that is extremely durable and flexible.

Key Features of PUR Adhesive Lamination:

Strong Adhesion: Works effectively with plastics, metals, wood, textiles, composites, and paper.

Moisture Resistance: Ideal for humid environments, preventing delamination.

Temperature Stability: Withstands extreme hot and cold conditions without losing bond integrity.

Durability: Maintains elasticity over time, avoiding cracking and peeling.

Eco-Friendly: Emits lower VOCs compared to solvent-based systems.

This makes PUR laminating machines highly suitable for automated laminating production systems, PUR panel laminating machine suppliers, and high-gloss PUR lamination applications.

Comparing PUR Laminating Machines with Other Methods

1. Hot Melt Lamination

The hot melt lamination process uses thermoplastic adhesives melted at high temperatures.

Adhesive Composition: Thermoplastics can be reheated and softened, unlike PUR adhesives that chemically cure.

Bond Strength: PUR glue laminating machines provide stronger, more durable bonds, especially under fluctuating conditions.

Heat Resistance: Hot melt adhesives soften under high heat, whereas PUR lamination machines maintain stability.

Industries: Furniture, textiles, and packaging.

2. Solvent-Based Lamination

Solvent-based laminating machines use adhesives dissolved in solvents, which evaporate to form bonds.

Environmental Impact: Produces VOC emissions, while PUR lamination glue supply is more eco-friendly.

Curing Time: Solvent-based requires evaporation; PUR cures faster with moisture.

Resistance: PUR adhesives outperform in chemical, moisture, and temperature resistance.

Industries: Flexible packaging, labels, high-performance films.

3. Water-Based Lamination

Water-based adhesives are dispersed in water and bond as the water evaporates.

Moisture Sensitivity: Can weaken in humid climates, unlike PUR adhesives.

Bond Strength: Less durable compared to PUR lamination glue.

Application Range: Mostly for paper and flexible films, while PUR laminating machines handle rigid substrates as well.

Industries: Paper packaging, eco-friendly laminating applications.

4. Film Lamination

This method bonds pre-coated or adhesive-backed films using heat and pressure.

Adhesion Type: Relies on surface adhesion, while PUR adhesive lamination penetrates deeply.

Flexibility: Film lamination may crack or peel; PUR remains elastic.

Applications: Books, posters, printed paper products.

Best for: Short-term protective layers, less suitable for demanding industrial environments.

Advantages of PUR Laminating Machines Over Other Methods

Superior Bonding Strength

PUR adhesives form molecular-level bonds, ensuring long-term adhesion.

Moisture & Heat Resistance

Ideal for industries exposed to humidity, heat, or cold storage conditions.

Versatile Material Compatibility

Works with wood panels, textiles, metal sheets, plastic films, composites—making it indispensable in industrial laminating lines.

Eco-Friendly Solution

Lower VOC emissions compared to solvent-based methods.

Flexibility & Durability

Bonds maintain elasticity, preventing cracking or separation in automated laminating production systems.

High Gloss & Aesthetic Finishes

High glossy PUR lamination machine manufacturers provide solutions for furniture, decorative laminates, and premium packaging.

Industrial Applications of PUR Lamination

Furniture & Woodworking: For bonding laminates to wood panels, ensuring long-lasting adhesion.

Flexible Packaging: Provides moisture-resistant seals for food, medical, and consumer goods.

Automotive Interiors: Ensures heat- and wear-resistant bonds for dashboards, door panels, and upholstery.

Electronics & Displays: Used for laminating protective films and functional layers.

Printing & Decorative Laminates: Creates high-gloss finishes for premium packaging, books, and signage.

Choosing the Right PUR Laminating Machine Company

When selecting a PUR lamination machine company or PUR glue laminating machine manufacturer, consider:

Experience in industrial laminating lines

Support for automated laminating production systems

Availability of low-cost PUR lamination glue supply

Proven track record with high glossy PUR lamination machine factories

Partnering with the right PUR laminating machine company ensures quality, efficiency, and long-term ROI.

Conclusion

While many laminating methods exist, PUR laminating machines clearly deliver superior performance, stronger bonds, eco-friendliness, and versatility. Compared to hot melt laminating machines, solvent-based, water-based, and film lamination systems, PUR adhesive lamination stands out as the most reliable option for advanced manufacturing environments.

As industries increasingly demand strong, sustainable, and flexible bonding solutions, the PUR laminating machine process will continue to dominate automated laminating production systems and industrial laminating lines worldwide.