A Comprehensive Guide To Pur Laminating Production Line

July 24, 2025

July 24, 2025 Hits:767second

Hits:767secondIn recent years, Algeria has witnessed a remarkable growth in its furniture, cabinetry, and decorative materials sector. With a strong demand for modern interiors and durable surface solutions, manufacturers are seeking advanced production technologies that offer high efficiency, outstanding finish quality, and long-term reliability. One such solution that has gained widespread attention is the PUR laminating production line—specifically used for bonding PVC decorative films onto acrylic boards. This guide provides a comprehensive overview of the PUR laminating process, its technical structure, applications in the Algerian market, and how manufacturers can strategically select between automatic and semi-automatic systems to align with their production goals and budgets.

Unlocking Market Potential: Why Algeria Is Embracing PUR Lamination

Algeria's growing urbanization, rising middle class, and increased spending on home improvement have significantly contributed to the development of the local furniture and building materials industries. As consumers demand not only aesthetics but also functionality—such as water resistance, heat tolerance, and long-lasting surface quality—the need for advanced lamination solutions has surged.

PUR (polyurethane reactive) adhesives are increasingly preferred over traditional hot melt adhesives due to their superior bonding strength, heat and moisture resistance, and ability to work with difficult-to-bond materials like acrylic boards and PVC films. These characteristics are particularly valuable in Algeria's varying climate conditions, where durability and performance are essential.

Material Focus: Laminating PVC Film onto Acrylic Boards

Acrylic boards have become popular in high-gloss furniture and cabinet production due to their clarity, flatness, and modern aesthetic appeal. However, their surface requires protection and enhancement, which is where PVC decorative films come into play.

These films can range from matte and gloss to woodgrain and metallic finishes. When bonded using PUR adhesive, the result is a laminated panel with superior appearance and functionality. This material combination is widely used in:

Kitchen cabinet doors

Wardrobe panels

Decorative wall panels

Modular furniture elements

From a technical standpoint, acrylic+PVC lamination presents challenges that PUR glue is well-suited to solve. Unlike EVA or standard hot melt glues, PUR reacts chemically with moisture in the air and substrate, forming a long-lasting bond that resists peeling, bubbling, or warping—even under heat or humidity stress.

Performance Benefits: What Functional Value Does PUR Bring?

The application of PUR lamination in acrylic-PVC panel production brings significant functional advantages, including:

Enhanced bonding strength: PUR adhesives create a chemical cross-link that permanently binds the film to the substrate, ideal for high-impact or long-use surfaces.

Moisture and humidity resistance: Unlike traditional adhesives, PUR is unaffected by moisture over time, preventing delamination in high-humidity zones.

Thermal stability: Laminated panels retain form and adhesion even in kitchen or bathroom environments with high temperature variations.

Smooth, bubble-free surfaces: PUR creates a uniform lamination layer with minimal glue lines or surface defects.

Chemical resistance: Finished panels are less likely to degrade under exposure to household cleaners or environmental pollutants.

These features translate to a longer lifespan for laminated products and an upgraded user experience—two critical factors for consumers and project developers in Algeria.

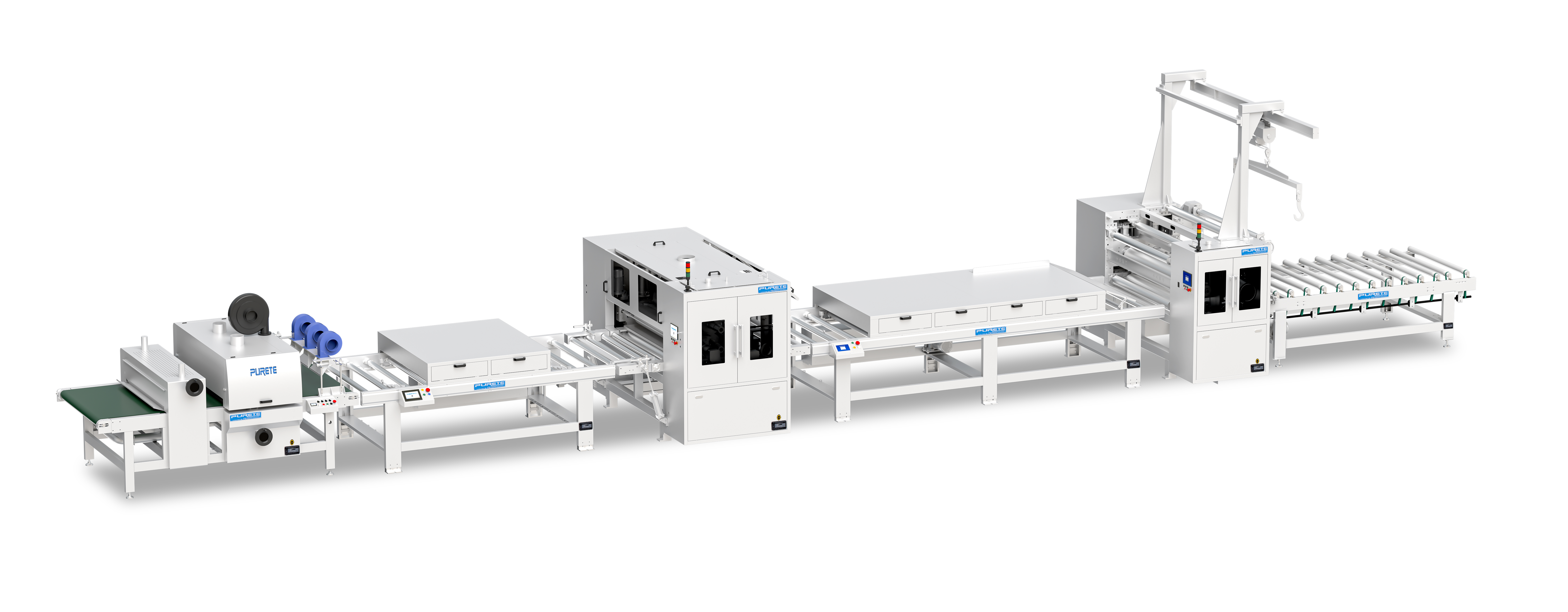

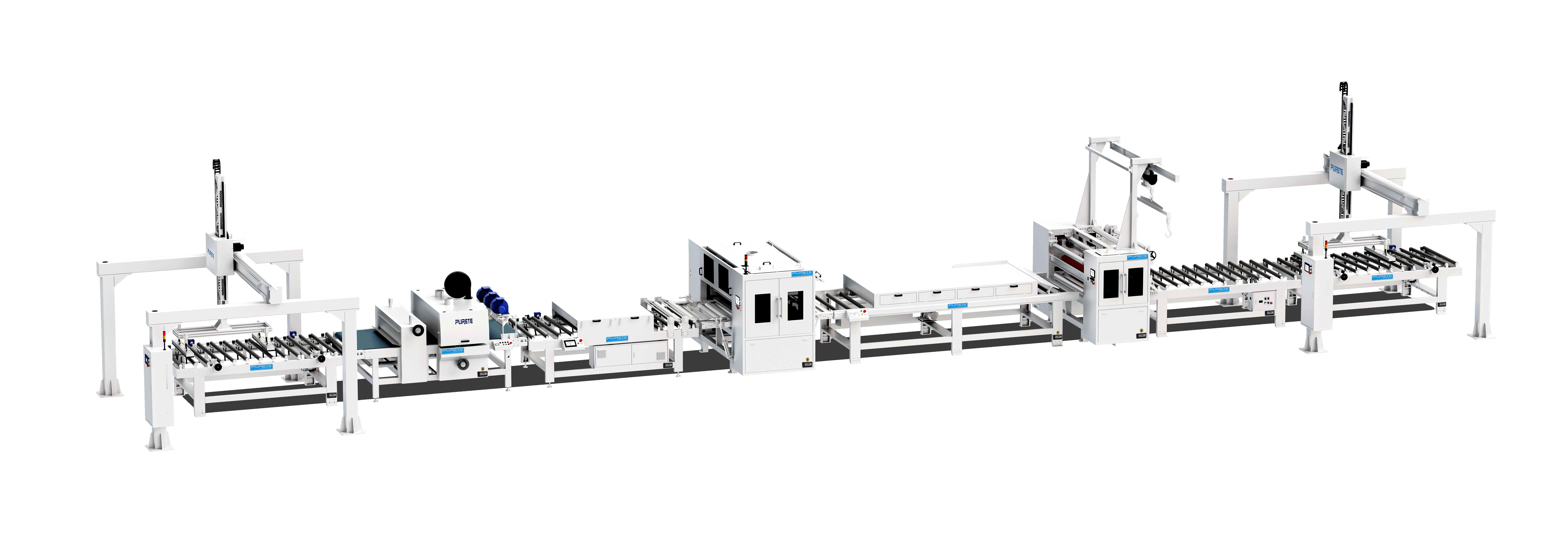

Production Line Structure: From Feeding to Final Lamination

A modern PUR laminating line consists of multiple integrated components that perform sequential operations. The following are key sections of the production line:

Panel Loading Station: Can be manual, semi-automatic, or fully automatic depending on factory layout.

Roller Conveyor System: Transports boards efficiently and aligns them for lamination.

Surface Cleaning Units: Typically include brushing systems, electrostatic removers, or plasma treatment to remove dust and improve adhesion.

Infrared Preheating Zone: Ensures the substrate reaches optimal temperature for PUR bonding.

PUR Glue Application Module: Delivers precise glue volumes and maintains stable viscosity, usually with closed-loop metering systems.

Laminating Press: Applies pressure via heated rollers or vacuum plates to bond the PVC film onto the board.

Edge Trimming & Final Stacking: Ensures uniform edges and prepares panels for post-processing or packaging.

The system can be expanded with optional components such as protective film applicators, automatic cutters, or digital width adjustment units.

Smart Configuration: Automatic vs. Semi-Automatic Lines

For Algerian manufacturers, the decision to invest in automatic or semi-automatic PUR laminating systems must be based on factors such as production volume, workforce availability, and investment capability.

Fully Automatic Lines: Designed for high-volume operations, these lines feature automated loading/unloading, in-line quality inspection, servo-controlled glue metering, and robotic stacking. They offer higher throughput, better consistency, and lower labor dependency.

Semi-Automatic Lines: Better suited for medium-sized factories or batch production. These systems retain automated core processes (gluing, pressing) but require manual loading and stacking. They are more affordable and easier to maintain, making them ideal for companies scaling up gradually.

The modular design of PURETE's lines allows future upgrades, enabling users to start with a semi-automatic system and expand to full automation when ready.

Customizing Your Line: Matching Function with Budget and Scale

PURETE offers flexible machine combinations tailored to different needs:

Basic Line: Includes loading, cleaning, PUR gluing, laminating, and manual trimming—ideal for startups.

Standard Line: Adds IR preheating, dual-side cleaning, edge trimming, and automated stacking.

Advanced Line: Fully automated, with optional features such as in-line cutting, adjustable width modules, and digital control panels.

For Algerian clients, additional considerations include local power conditions, available plant space, workforce skill levels, and access to technical support. PURETE provides layout consultation, installation supervision, and long-term service partnerships to ensure a smooth ramp-up.

PURETE's Lamination Solutions for the Algerian Market

As a professional equipment supplier, PURETE has delivered high-performance PUR laminating solutions to clients across emerging markets, including North Africa. For Algeria, PURETE offers:

Models specifically designed for acrylic board + PVC film lamination

Semi-automatic and fully automatic lines to match different budgets

Custom engineering to match space, capacity, and product types

Technical documentation in French and Arabic upon request

On-site commissioning and operator training for local teams

Our systems are built for durability, easy maintenance, and seamless integration into furniture and panel production environments in Algeria.

Conclusion

The PUR laminating production line represents a significant leap in both technology and product quality for Algerian manufacturers seeking to compete in today's demanding furniture and interior markets. By utilizing high-performance PUR adhesives and modern automation options, producers can achieve superior laminated panels that meet customer expectations in durability, visual appeal, and cost-effectiveness.

Whether you are a startup aiming to produce custom panels or an established factory planning to scale operations, choosing the right system configuration is critical to long-term success. With extensive expertise, localized support, and tailored machinery, PURETE stands ready to help Algerian manufacturers build competitive, future-ready lamination capabilities.