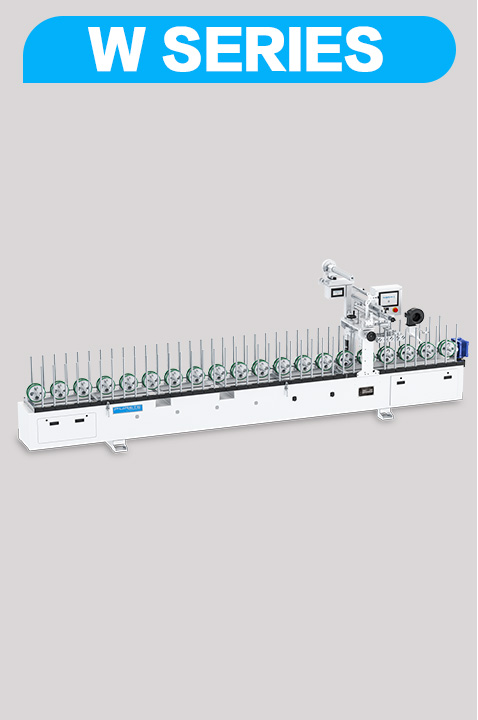

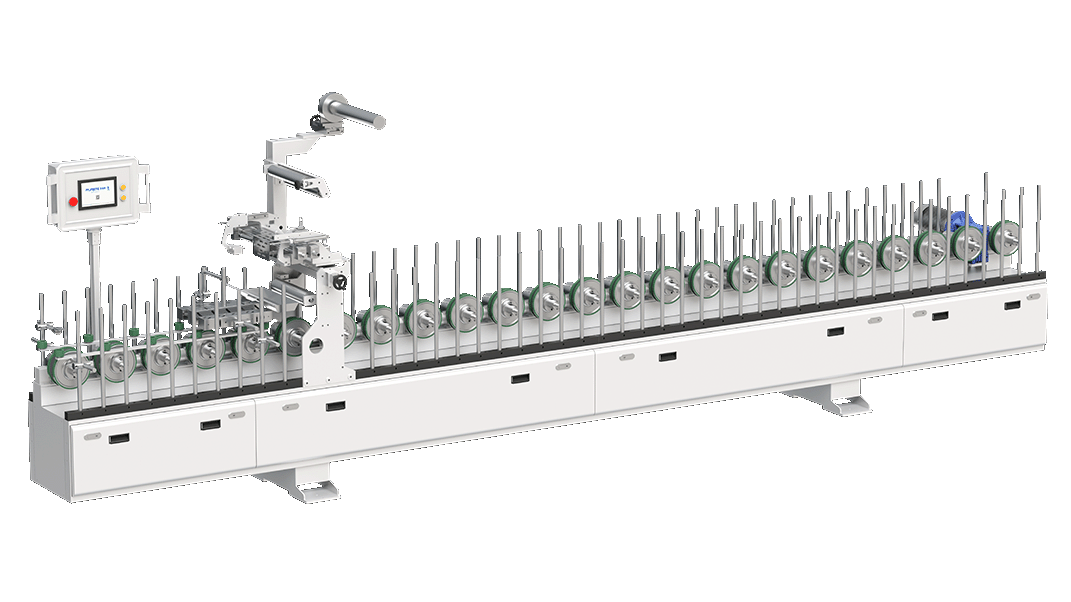

FBF-33-L Section Bar Wrapping Machine with Hot Melt Adhesive

The FBF-33-L section bar wrapping machine is designed for precise and efficient profile wrapping using advanced hot melt adhesive technology. As the profile moves along the conveyor, a specialized gluing device sprays and scrapes PUR or conventional hot melt adhesive onto the back of the wrapping material, simulating manual lamination. The decorative surface material is then adhered to the substrate through point-by-point pressing by pressure rollers and molding wheels, achieving a seamless composite finish.

Engineered for industrial applications, this section bar wrapping machine ensures consistent adhesion, high-quality surface finishing, and improved production efficiency. Ideal for furniture profiles, decorative panels, and architectural components, the FBF-33-L integrates automation and precision to reduce labor costs while maintaining superior quality.

Read more

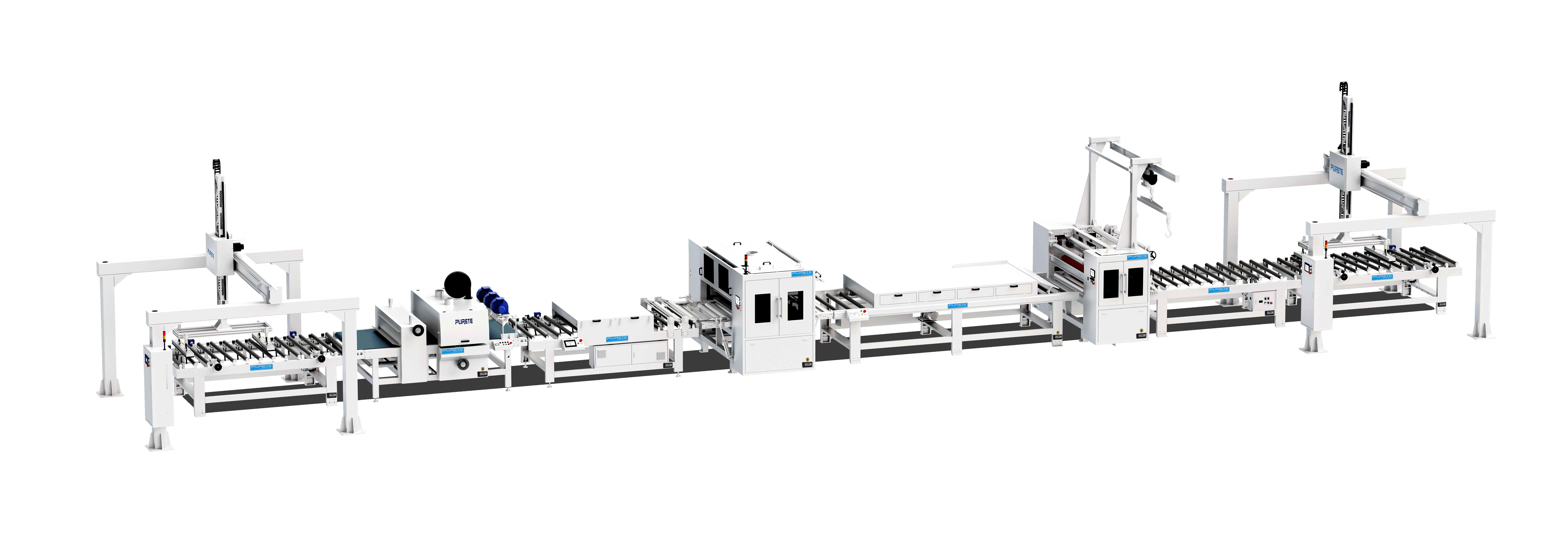

T2 Automatic Laminating Production Line

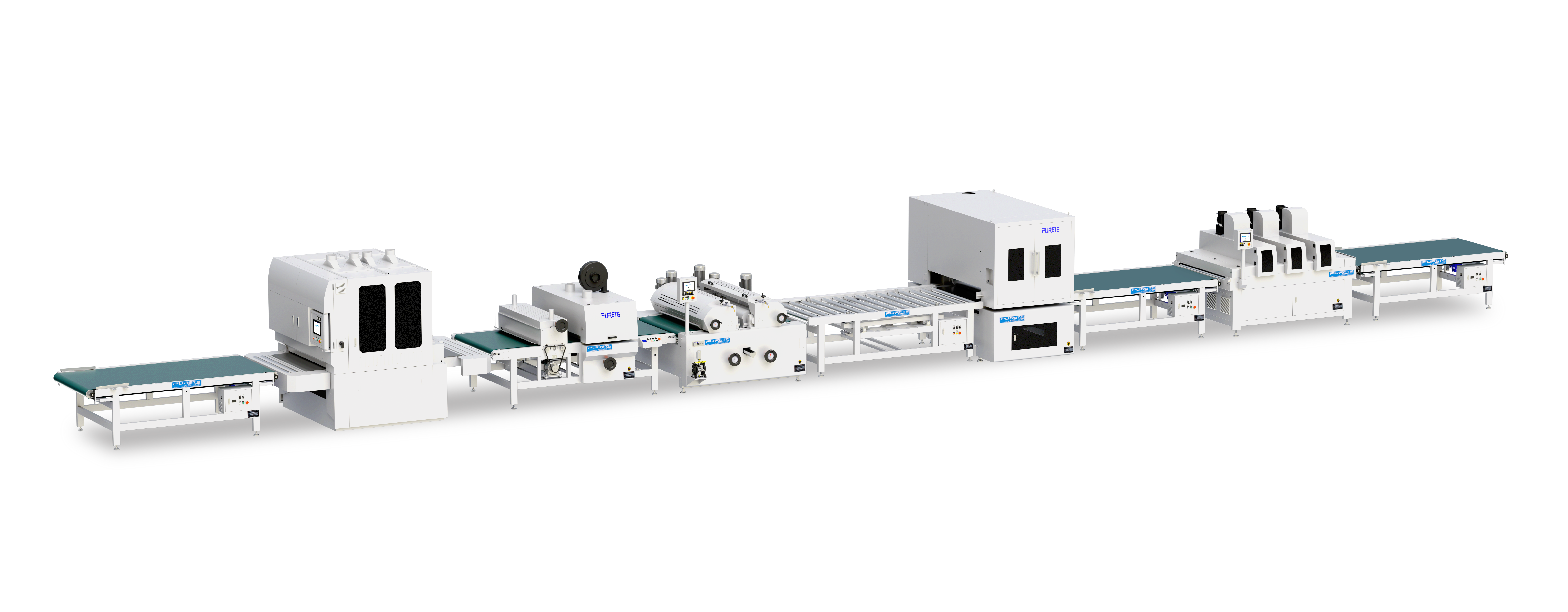

The T2 Automatic Laminating Production Line is designed for high-efficiency, automated panel lamination, integrating a gantry loading and unloading system to significantly reduce manual handling and labor intensity. This intelligent setup improves production efficiency, safety, and operational precision, making it ideal for continuous large-scale manufacturing.

The line supports PUR and hot-melt adhesive lamination for various substrates such as MDF, plywood, PET, PVC, and decorative sheets. It ensures smooth surface finishes, strong bonding, and uniform coating quality—perfect for furniture, doors, and interior wall panels.

Composed of: Gantry loading, polishing and dust removal system, gluing machine, laminating machine, and unloading system.

Read more

M2 3D Embossing Production Line with UV Coating Technology

The M2 3D embossing production line is engineered to deliver premium decorative finishes with realistic 3D effects. By applying a uniform layer of UV paint to the flat surface of the workpiece and pressing it with a decorative film, the system transfers intricate textures and patterns onto the surface. This process produces stunning embossed effects with high precision, durability, and consistency.

The complete line is composed of a sanding machine, polishing machine, double-roller coating machine, advanced 3D embossing machine, and a three-lamp UV curing system. Designed for industrial-scale applications, the M2 production line ensures high efficiency, superior surface quality, and versatile design possibilities for furniture, flooring, and decorative panels.

Read more