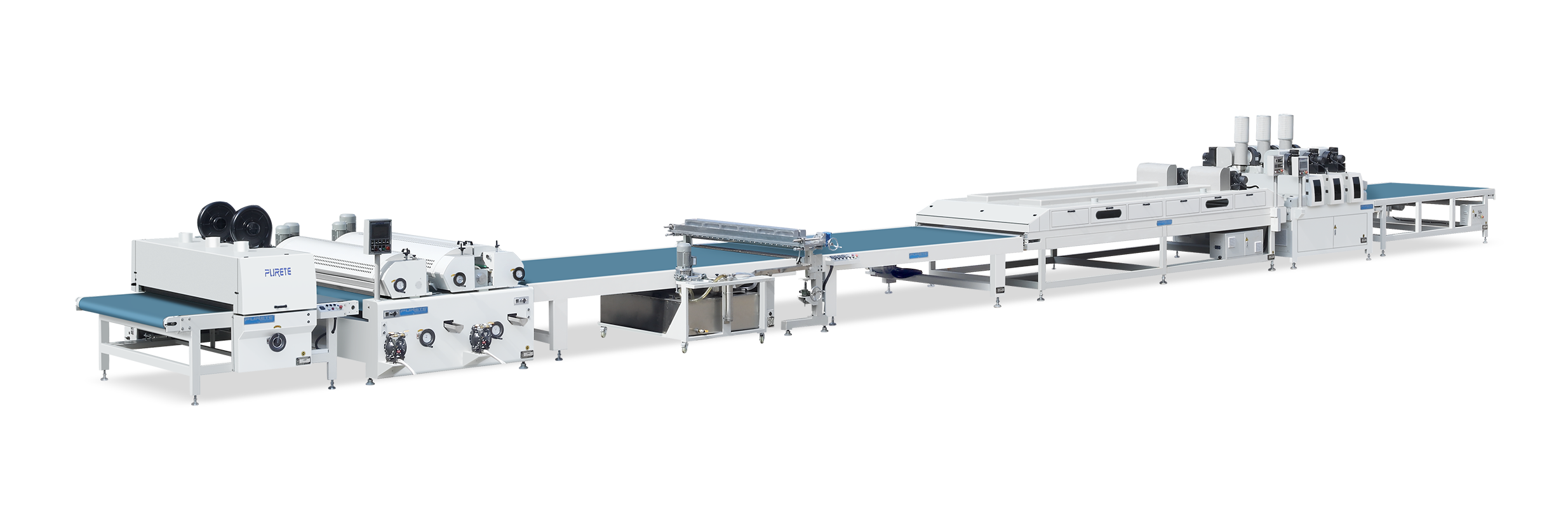

L10A-1950 Curtain Coating Production Line for Wide High-Gloss Panels

The L10A-1950 curtain coating production line is specially designed for wide-format, large-scale substrates that require premium high-gloss surface finishing. It is ideal for coating materials such as marble-effect panels, melamine (three-amine) boards, and other decorative wall panels. This advanced system delivers a mirror-like finish with exceptional smoothness, brilliance, and durability—perfect for high-end interior decoration applications.

The complete line is composed of a dust cleaner, forward and reverse coater, curtain coater, 12-meter IR heating oven, and a three-lamp UV curing unit. Engineered for industrial-scale production, the L10A-1950 offers stable coating performance, consistent quality, and excellent efficiency, meeting the demands of modern architectural and decorative panel manufacturing.

Read more

G2-A Multi-Functional Roller Coating Production Line

The G2-A roller coating production line is a versatile UV coating solution designed for single standard product batch orders and mixed oil coatings. With fast processing speeds and stable, uniform coating performance, this automated line enables multi-coating operability in a single production workflow. The system integrates a dust removal unit, a combined filling and roller coating machine, dual-lamp UV curing, a three-roller coating setup, a 6-meter IR heating oven, and an additional three-lamp UV curing station. Ideal for industrial applications requiring flexibility and high efficiency, the G2-A ensures consistent quality while reducing labor requirements and enhancing production capacity.

Read more

5-Axis Spraying Painting Production Line for Complex and Irregular Workpieces

The 5-axis spraying painting production line is an intelligent surface coating system featuring a five-axis linkage control for precise automatic spraying on multiple angles and complex curved surfaces. This advanced technology ensures uniform coating, superior finish quality, and high efficiency for irregular-shaped workpieces.

Widely applied in furniture, cabinets, doors, automotive parts, and other customized products, the 5-axis line enables flexible and automated production for industrial-scale operations. Its high-precision control, consistent coating performance, and versatility make it ideal for manufacturers seeking top-quality surface finishes on complex geometries.

Read more