M3 Transfer and Embossing Production Line for Stone-Like Effects

The M3 transfer and embossing production line is designed to replicate realistic stone textures on substrates using advanced transfer printing and embossing technology. By transferring the decorative pattern from the film onto the surface, materials such as calcium silicate boards can be transformed into stone-like finishes including rock board and marble effects. This process provides high aesthetic value, durability, and consistency, making it ideal for decorative building materials and furniture applications.

The complete system is composed of a dust cleaner, double-roller coating machine, 6-meter IR leveling oven, transfer process unit, 3D embossing machine, and a three-lamp UV curing station. With efficient automation, stable performance, and versatile design capabilities, the M3 production line delivers premium decorative finishes while improving productivity and reducing labor costs.

Read more

G3 Large-Scale Roller Coating Production Line

The G3 large roller coating production line is a fully customizable solution for wide panels, with coating widths ranging from 320 mm to 2550 mm, suitable for oversized wall panels up to 2.44 × 3.66 meters. Designed to achieve efficient one-line multi-coating, it is ideal for export-oriented factories and international enterprises seeking high-quality surface finishes. This advanced production line integrates polishing and dust removal systems, single and multi-roller coating units, three-lamp UV curing stations, a combined filling and roller coating machine, and a 6-meter IR heating oven for optimal coating performance. With automated precision and stable coating effects, the G3 line ensures superior surface quality, increased productivity, and reduced labor costs.

Read more

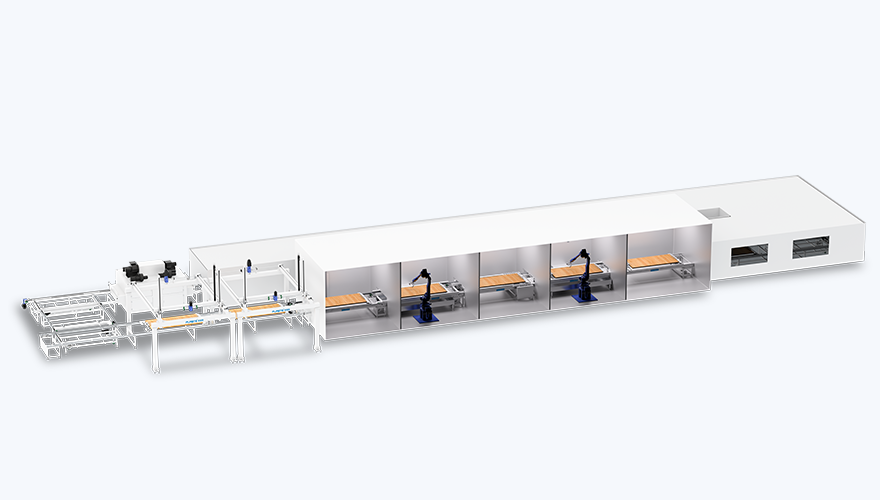

Robotic Automatic Spraying Production Line

The Robotic Automatic Spraying Production Line adopts advanced robotic arm technology for fully automated, high-precision surface coating. It ensures uniform spraying, consistent film thickness, and stable color quality even on complex or irregular-shaped workpieces.

With its intelligent programming system, the robotic sprayer can flexibly adjust spray angles and trajectories to meet diverse coating requirements. This line is ideal for furniture, cabinet doors, automotive parts, and decorative panels, supporting both UV and water-based coatings.

It significantly improves production efficiency, reduces labor costs, and enhances coating consistency across large-scale operations.

Composed of: Robotic spraying system, dust cleaner, automatic conveyor, IR leveling oven, and UV curing system.

Read more