Why PUR Laminating Lines Are Essential for Durable Decorative Panels in the Middle East

August 20, 2025

August 20, 2025 Hits:480second

Hits:480secondThe Middle East is one of the fastest-growing regions in terms of construction, interior design, and furniture manufacturing. With a rising demand for high-quality decorative panels that can withstand extreme climate conditions, manufacturers are constantly searching for durable and reliable surface finishing technologies. Among the available solutions, PUR laminating lines have become the preferred choice for producing MDF, particle boards, and other composite panels used in furniture, doors, and interior applications.

This article explores what PUR lamination is, why it is essential in the Middle East, and how PURETE supports manufacturers with advanced PUR laminating line solutions across the region.

What Is PUR Lamination and How Does It Work?

PUR, or Polyurethane Reactive hot-melt adhesive, is a high-performance adhesive that reacts with moisture in the air to create a strong, heat-resistant, and water-resistant bond. Unlike traditional EVA adhesives, PUR adhesives form a cross-linked bond that provides excellent durability even under extreme temperatures and humidity changes.

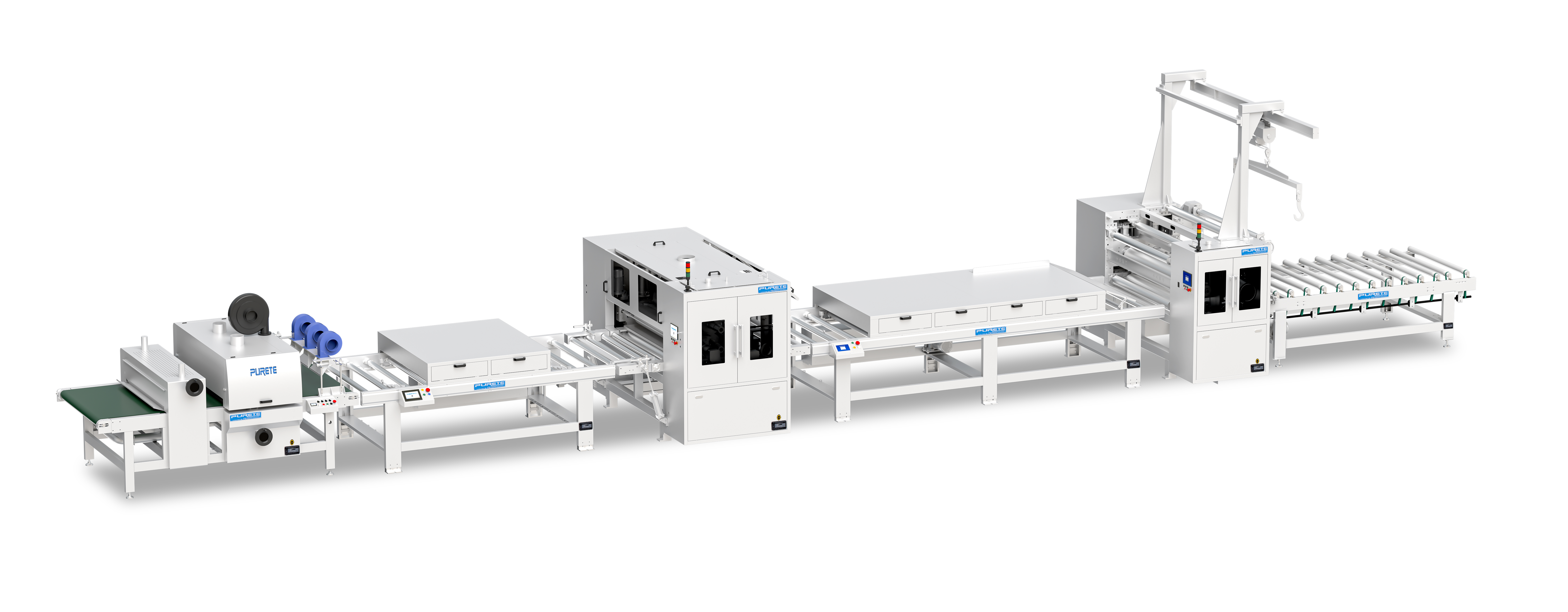

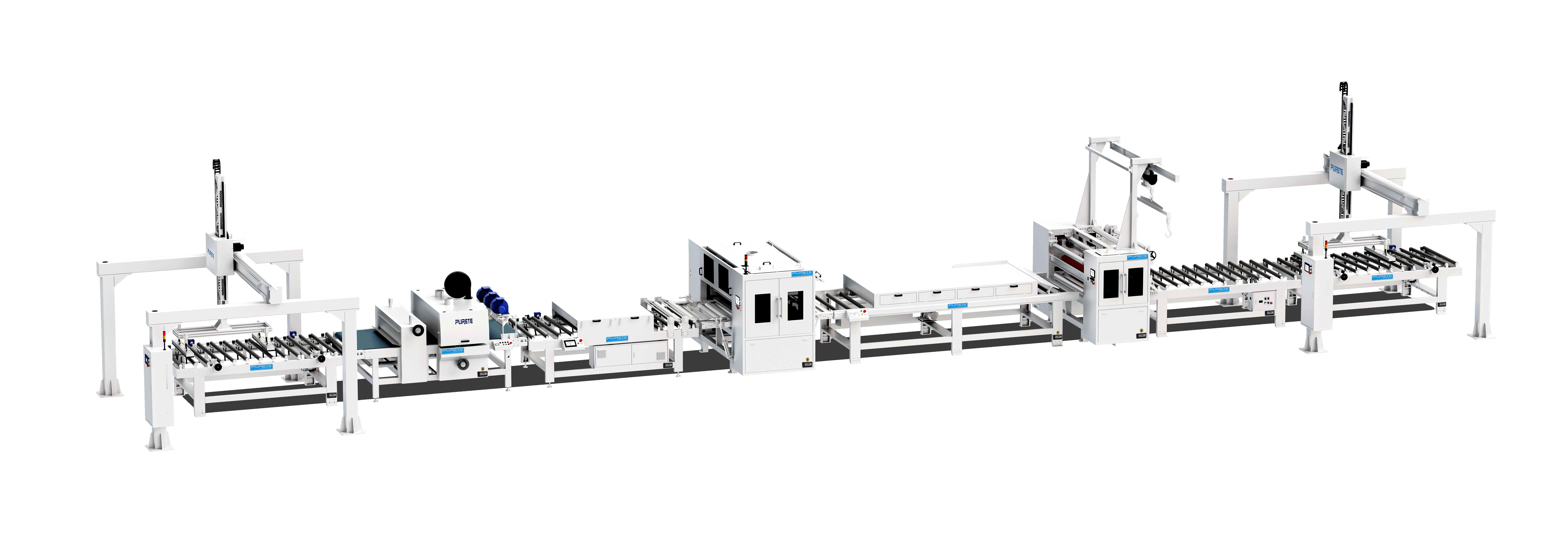

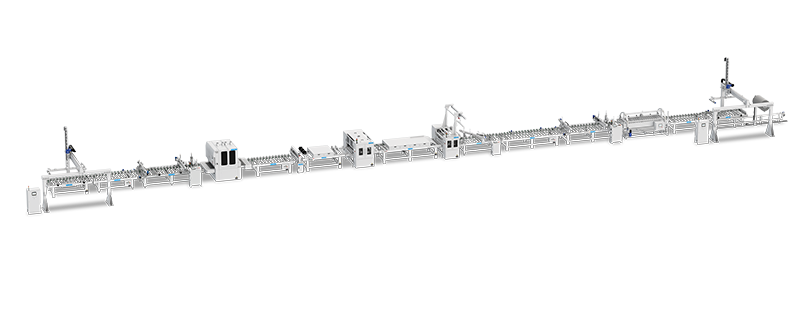

A PUR laminating line uses this adhesive to bond decorative films, foils, or veneers onto substrates such as MDF and particle boards. The process ensures seamless bonding, resistance to delamination, and superior surface quality—making PUR the industry standard for decorative panels in demanding environments.

Challenges in Middle Eastern Climate Conditions

The Middle East presents unique challenges for wood-based panel manufacturers:

High temperatures: In countries like Saudi Arabia, UAE, and Qatar, surface finishes must resist intense heat without deforming or peeling.

Humidity fluctuations: In coastal regions, panels face moisture and humidity, which can cause swelling or adhesive failure if not properly treated.

Sand and dust exposure: Dust particles in the air can damage surface quality if adhesives or laminates are not strong enough.

In these conditions, traditional adhesives such as EVA often fail, leading to delamination, bubbling, or warping. This is why PUR lamination is essential—it guarantees long-term durability and resistance under the region's harsh climate.

Benefits of PUR Laminating Lines for MDF and Particle Boards

When applied to MDF, particle boards, and similar substrates, PUR lamination offers unmatched benefits:

Superior durability – PUR bonds penetrate deep into the substrate, preventing peeling or delamination.

Heat and water resistance – Essential for the Middle Eastern environment, where extreme weather is common.

Aesthetic appeal – Decorative foils, PVC, PET, or veneer finishes maintain a seamless and smooth surface.

Eco-friendly advantages – Lower adhesive usage and longer product life reduce material waste.

Versatility – Suitable for flat panels, curved shapes, doors, cabinets, and furniture parts.

By investing in PUR laminating lines, manufacturers ensure long-lasting quality, cost efficiency, and customer satisfaction.

Key Industries Using PUR Lamination (Furniture, Interior Panels, Doors)

Several industries across the Middle East rely heavily on PUR laminating technology:

Furniture manufacturing – MDF and particle boards laminated with PUR provide scratch-resistant, heat-resistant, and stylish finishes for modern furniture.

Interior panels – From office spaces in Dubai to luxury villas in Qatar, interior wall panels require durability and premium design.

Doors and cabinetry – PUR ensures doors and cabinets remain stable and elegant even in humid or hot conditions.

Commercial interiors – Hotels, shopping malls, and offices benefit from long-lasting decorative panels that reduce maintenance costs.

With these applications, it is clear that PUR lamination has become the backbone of Middle Eastern panel finishing.

Customization and Automation for Regional Manufacturing Needs

The Middle Eastern market is diverse, with manufacturers demanding customized and automated solutions to meet their production targets. Modern PUR laminating lines offer:

Fully automated systems for consistent production and reduced labor costs.

Customization options to handle different substrates, film thicknesses, and finishes.

High-speed lines for large-scale manufacturers.

Compact systems for smaller workshops seeking efficiency and flexibility.

Automation not only improves production capacity but also ensures consistent adhesive application and flawless finishing, essential for competitive regional markets.

Why PURETE Is a Trusted Partner for PUR Laminating Lines in the Middle East

As a global leader in surface finishing and laminating equipment, PURETE has established a strong presence in the Middle East, offering reliable PUR laminating solutions for manufacturers in the region.

PURETE's Advantages in the Middle East:

Regional offices and presence: PURETE operates across Iran, Dubai, Turkey, Qatar, and Saudi Arabia, ensuring fast customer support and service.

On-site engineers: With experienced engineers stationed overseas year-round, PURETE provides installation, training, and maintenance services directly at the customer's site.

Remote technical assistance: Manufacturers benefit from remote installation guidance and troubleshooting, reducing downtime and ensuring smooth production.

Logistics support: PURETE offers efficient delivery and spare parts logistics, ensuring uninterrupted operations.

Customization services: From large-scale factories to smaller workshops, PURETE designs tailored PUR laminating lines that match each customer's production requirements.

With these strengths, PURETE has become the trusted partner for furniture, interior, and panel manufacturers across the Middle East, supporting both small businesses and large-scale enterprises.

Conclusion

The Middle Eastern climate poses significant challenges for decorative panels, but with the right technology, manufacturers can achieve durability, aesthetic appeal, and long-term performance. PUR laminating lines are essential for MDF, particle boards, and furniture components in this demanding market.

As a recognized leader in laminating solutions, PURETE provides cutting-edge PUR laminating lines tailored to regional needs. With local offices, expert engineers, and strong logistics support in the Middle East, PURETE ensures manufacturers receive not only reliable equipment but also a trusted long-term partnership.

For manufacturers aiming to stay competitive, investing in PURETE's PUR laminating technology is the key to delivering durable, high-quality decorative panels for today's growing market.