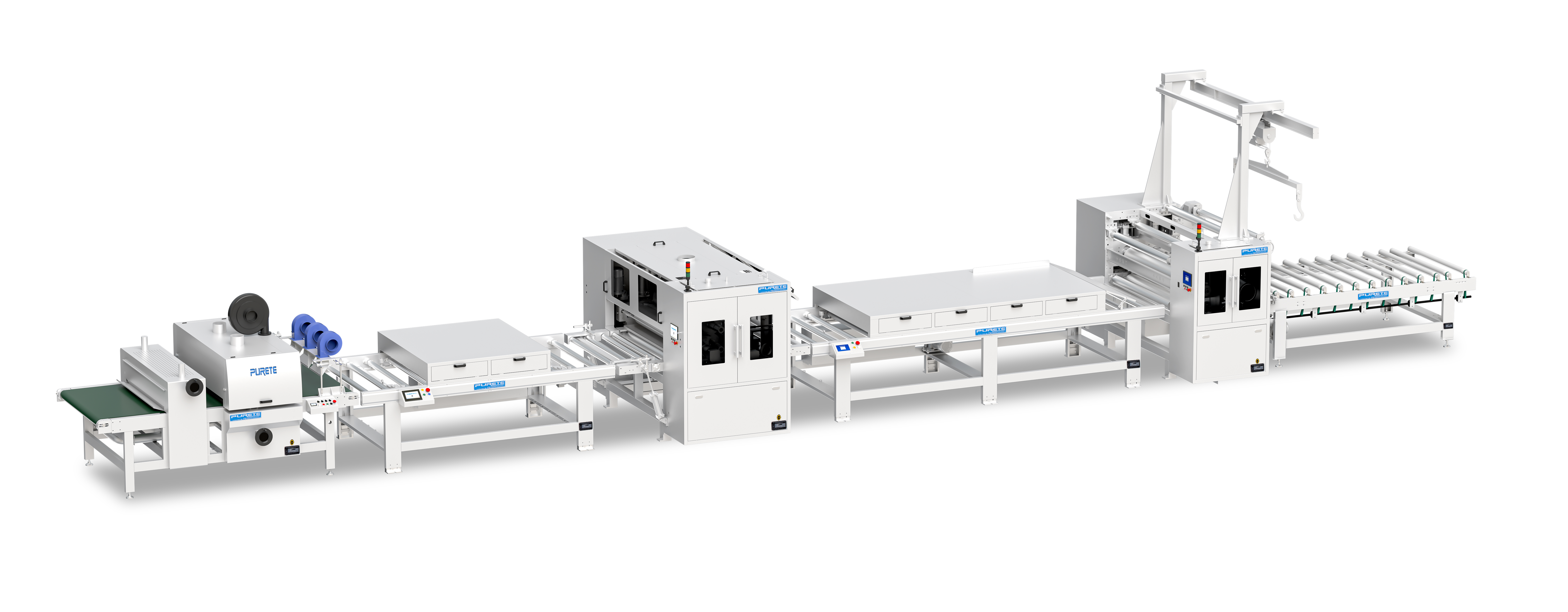

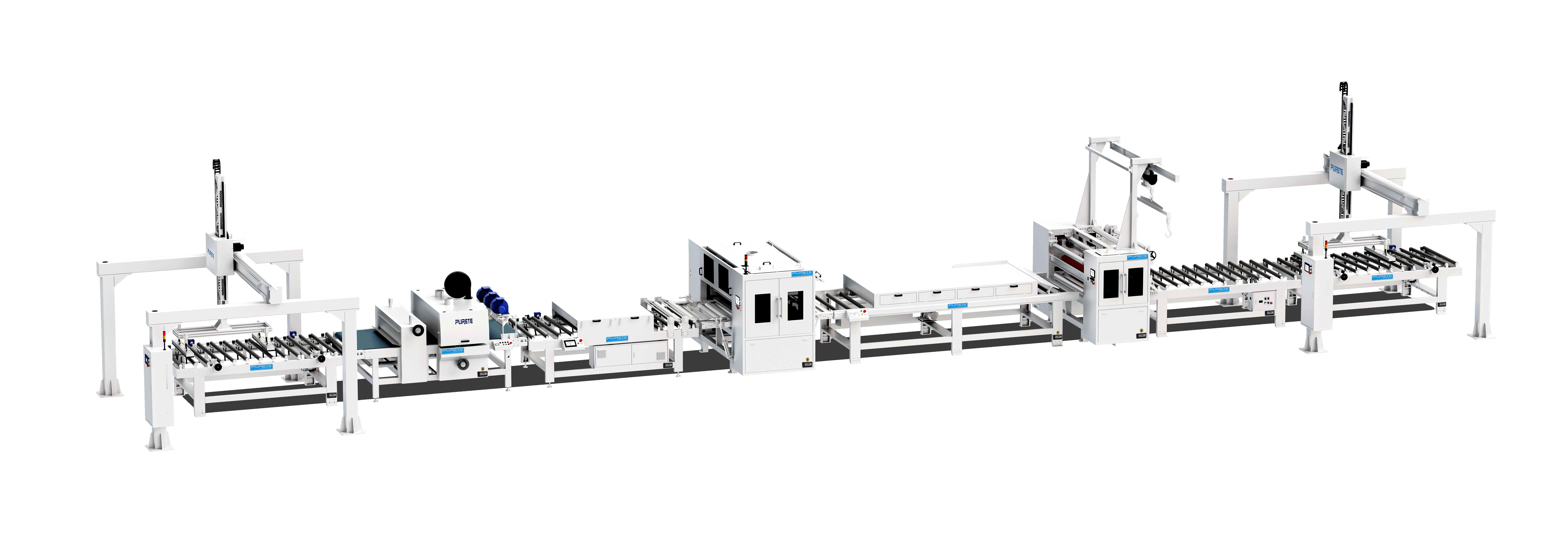

PUR Laminating Production Line for High-Speed Lamination Processes

January 16, 2026

January 16, 2026 Hits:11second

Hits:11secondAs furniture, panel, and interior component manufacturers pursue higher output and shorter delivery cycles, high-speed lamination has become a core competitive capability. At the same time, rising expectations for surface durability, moisture resistance, and long-term bonding strength have driven widespread adoption of PUR (polyurethane reactive) adhesives.

A PUR laminating production line combines these two demands—speed and performance—into a single, continuous system designed for industrial-scale manufacturing. Compared with conventional EVA-based lamination, PUR laminating lines enable faster processing, stronger adhesion, and superior resistance to heat, humidity, and chemicals.

This article explores the structure and function of a high-speed PUR laminating production line, examines how manufacturers optimize lamination processes, addresses common challenges in high-speed operation, and explains how performance-focused system design—such as that offered by PURETE—supports reliable, long-term production.

Key Components of a High-Speed PUR Laminating Line

A high-speed PUR laminating line is not a single machine, but a fully integrated system where each component must operate in precise coordination. Any imbalance can compromise bonding quality or line stability.

Panel Feeding and Infeed System

High-speed production begins with a stable infeed. Automatic feeding systems ensure:

Consistent panel spacing

Accurate alignment at high line speeds

Reduced operator intervention

Vacuum feeders or roller-based systems are commonly used for MDF, particleboard, plywood, and composite panels.

Surface Preparation Unit

Before adhesive application, panels may pass through cleaning or preheating stations. Removing dust and stabilizing surface temperature improves PUR adhesive wetting and bonding performance, especially at elevated speeds.

PUR Adhesive Application System

The glue unit is the heart of a PUR laminating production line. Key characteristics include:

Precise glue metering and coating thickness control

Stable temperature management for reactive PUR adhesives

Rapid response to speed changes

Slot die coaters or roller coaters are typically used to ensure uniform adhesive distribution, even at high throughput.

Film or Decorative Material Unwinding

High-speed lamination demands smooth, tension-controlled unwinding of decorative materials such as:

PVC and PET films

CPL and HPL laminates

Decorative paper and functional foils

Automatic tension control systems prevent wrinkles, stretching, or misalignment as line speed increases.

Laminating and Pressing Section

Press rollers or belt presses apply controlled pressure to ensure full contact between panel, adhesive, and decorative layer. At high speeds, pressure consistency is critical to prevent delamination or air entrapment.

Cooling, Trimming, and Stacking

After lamination, panels are cooled to stabilize bonding, then trimmed and stacked automatically for downstream processing. Efficient outfeed systems help maintain continuous production without bottlenecks.

Process Optimization for High-Speed Lamination

Running a PUR laminating line at high speed requires more than powerful motors—it depends on process optimization across the entire line.

Adhesive Spread and Open Time Control

PUR adhesives have specific open times. At high speeds, manufacturers must carefully balance:

Glue application thickness

Panel temperature

Line speed

Optimized glue spread ensures complete bonding before curing begins, even during rapid processing.

Temperature Management

Stable temperature control across glue units, panels, and decorative materials is essential. Excessive heat can degrade adhesive performance, while insufficient heat may reduce wetting and bond strength.

Synchronization of Line Speed

All line components—from feeding to pressing—must remain synchronized. Modern laminating lines use centralized control systems to adjust speeds dynamically, maintaining consistent lamination quality.

Material Compatibility Testing

High-speed PUR lamination often involves diverse substrates and films. Manufacturers routinely test material combinations to ensure compatibility under accelerated conditions.

Challenges in High-Speed PUR Lamination

While high-speed PUR laminating lines offer significant advantages, they also introduce technical challenges that must be carefully managed.

Adhesive Reactivity at High Throughput

PUR adhesives react with moisture to cure. At high speeds, improper control can lead to:

Incomplete bonding

Premature curing in glue systems

Increased maintenance requirements

Advanced glue management systems are essential to mitigate these risks.

Surface Defects and Quality Consistency

Higher speeds increase the likelihood of defects such as:

Bubbles or air pockets

Edge lifting

Inconsistent surface texture

Maintaining quality requires precise pressure control and stable material handling.

Equipment Wear and Maintenance

High-speed operation places greater stress on rollers, belts, and drive systems. Without proper design and maintenance planning, downtime can offset productivity gains.

Operator Skill and Process Knowledge

Although automation reduces manual labor, skilled operators are still needed to monitor parameters, adjust recipes, and respond to material changes in real time.

How Manufacturers Improve Line Performance

Leading manufacturers continuously refine their PUR laminating processes to maximize efficiency and reliability.

Automation and Digital Control

Modern laminating lines feature PLC systems, touch-screen interfaces, and stored production recipes. These tools enable:

Faster changeovers

Reduced setup errors

Repeatable production quality

Preventive Maintenance Strategies

Scheduled maintenance programs, supported by real-time monitoring, help prevent unexpected failures and extend equipment lifespan.

Modular Line Design

Modular system layouts allow manufacturers to upgrade individual sections—such as glue units or pressing modules—without replacing the entire line.

Collaboration with Equipment Suppliers

Close cooperation with experienced machinery suppliers ensures that line configuration, adhesive selection, and process parameters are optimized for specific production goals.

PURETE's High-Speed PUR Laminating Lines Balance Speed, Bonding Quality, and Reliability

PURETE is recognized in the woodworking and panel processing industry for delivering high-speed PUR laminating production lines that emphasize process stability as much as output capacity.

Rather than focusing on speed alone, PURETE designs laminating systems that balance:

Consistent PUR adhesive application

Reliable bonding performance across different materials

Line stability during long production runs

PURETE's solutions are commonly applied in furniture, cabinet, door, and decorative panel manufacturing, where surface quality and durability are as critical as throughput. By integrating adhesive systems, pressing technology, and automation controls into a cohesive line, PURETE supports manufacturers seeking scalable, high-performance lamination solutions.

Conclusion

A high-speed PUR laminating production line is a strategic investment for manufacturers aiming to improve productivity while meeting rising standards for surface quality and durability. When properly designed and optimized, PUR lamination enables faster output, stronger bonding, and broader material compatibility than traditional lamination methods.

However, success in high-speed PUR lamination depends on more than raw speed. Process control, system integration, adhesive management, and equipment reliability all play essential roles. Working with experienced solution providers—such as PURETE—helps manufacturers achieve stable, long-term performance while maximizing the benefits of PUR technology.

As furniture and panel production continues to evolve, high-speed PUR laminating lines will remain a key driver of efficiency, quality, and competitive differentiation.