PUR Laminating Production Line Explained: Process, Advantages, and Uses

January 21, 2026

January 21, 2026 Hits:59second

Hits:59secondAcross furniture, construction materials, and interior finishing industries, manufacturers are seeking lamination solutions that deliver high bonding strength, long-term durability, and stable performance under demanding environmental conditions. This demand is especially strong in emerging and fast-growing markets such as Algeria and other African countries, where temperature fluctuations, humidity, and heavy daily use place higher stress on laminated surfaces.

A PUR laminating production line has become a preferred solution for these conditions. Using polyurethane reactive (PUR) adhesive technology, these production lines enable continuous, high-quality lamination of PET-G films onto a wide range of substrates—including calcium silicate board, particleboard, metal panels, aluminum honeycomb panels, acrylic sheets, and acoustic insulation materials.

In this article, we explain how a PUR laminating production line works, its key advantages, typical application scenarios, comparisons with other lamination methods, and how to select the right system. We also share how PURETE supports industrial customers with customizable PUR laminating solutions designed for continuous operation and regional production needs.

How a PUR Laminating Production Line Works

A PUR laminating production line is a continuous industrial system designed to bond decorative or functional films—most commonly PET-G—onto flat substrates with high strength and stability.

Step-by-Step Lamination Process

Panel Feeding and Alignment

Substrates such as calcium silicate boards, particleboard, metal sheets, or aluminum honeycomb panels are fed automatically into the line. Accurate alignment ensures uniform lamination at high speed.

Surface Preparation

Panels pass through cleaning or preheating units to remove dust and stabilize surface temperature. This step is critical when laminating PET-G films, as it improves adhesive wetting and surface bonding.

PUR Adhesive Application

A controlled PUR glue application system applies adhesive evenly across the panel surface. Unlike thermoplastic adhesives, PUR chemically reacts with moisture to form a highly durable bond.

Film Unwinding and Lamination

PET-G film is unwound under precise tension control and laminated onto the substrate through heated rollers or belt presses. Pressure and temperature are synchronized with line speed.

Cooling and Stabilization

After lamination, panels are cooled to stabilize the adhesive layer before trimming, stacking, or further processing.

This continuous process allows PUR laminating lines to operate efficiently at industrial scale while maintaining consistent surface quality.

Key Advantages of PUR Laminating Lines

PUR laminating technology offers several advantages that make it especially suitable for African and North African markets, including Algeria.

Superior Bonding Strength

PUR adhesives create a chemical bond rather than a purely physical one. This results in excellent adhesion between PET-G films and challenging substrates such as metal sheets, aluminum honeycomb panels, and calcium silicate boards.

High Resistance to Heat and Humidity

Finished panels laminated with PUR perform reliably under high temperatures and humid conditions—an important advantage in regions with hot climates or variable environmental conditions.

Excellent Surface Quality

PET-G films laminated using PUR technology provide:

Smooth, uniform appearance

Scratch and wear resistance

Stable color and texture over time

This makes PUR lamination ideal for visible architectural and furniture components.

Wide Material Compatibility

PUR laminating production lines can handle a broad range of substrates and decorative films, enabling manufacturers to diversify product offerings without changing core equipment.

Long-Term Durability

Compared with conventional adhesives, PUR-laminated panels maintain bond integrity over long service lifetimes, reducing warranty issues and after-sales risk.

Typical Applications of PUR Laminating Production Line

PUR laminating production lines are used across multiple industries. When combined with PET-G films, their application scope expands even further.

Calcium Silicate Board Lamination

Calcium silicate boards are widely used for wall panels, ceilings, and fire-resistant construction materials. PUR lamination with PET-G improves surface appearance while maintaining structural performance.

Acoustic Panels and Silent Mats

In commercial buildings and residential developments, acoustic panels and silent mats benefit from PET-G lamination for durability, easy cleaning, and decorative finishes.

Particleboard and MDF Panels

Furniture carcasses, wardrobes, cabinets, and interior panels commonly use particleboard or MDF. PUR lamination ensures strong bonding and moisture resistance, especially in kitchens and bathrooms.

Acrylic Sheet Lamination

PUR laminating lines are suitable for laminating PET-G films onto acrylic sheets used in decorative panels, signage, and interior design applications.

Metal Panels and Composite Boards

Metal sheets and composite boards are increasingly used in modern construction and furniture. PUR adhesives ensure reliable bonding between PET-G films and non-porous metal surfaces.

Aluminum Honeycomb Panels

Lightweight aluminum honeycomb panels are widely used in architectural cladding and furniture structures. PUR lamination provides excellent adhesion while preserving panel flatness and strength.

PUR Lamination vs Other Methods

Understanding how PUR lamination compares with other techniques helps manufacturers choose the right solution.

PUR vs EVA Lamination

PUR: Stronger bonding, higher heat and moisture resistance, suitable for demanding environments

EVA: Lower cost but reduced durability and environmental resistance

For Algeria and African markets, PUR is often preferred for long-term performance.

PUR Lamination vs Painting

Lamination offers consistent surface quality and lower VOC emissions

Painting requires more labor and has higher variability

PUR Lamination vs Manual Sheet Gluing

Manual methods lack consistency and scalability, while PUR laminating lines provide repeatable industrial output.

Selecting a PUR Laminating Line

Choosing the right PUR laminating production line depends on production goals and material requirements.

Key Selection Factors

Manufacturers should evaluate:

Substrate types (calcium silicate, particleboard, metal, aluminum honeycomb)

Decorative materials (primarily PET-G)

Required line speed and output capacity

Environmental conditions and climate

Integration with existing production lines

Importance of Customization

Each factory has unique requirements. A customizable laminating line ensures optimal performance for specific materials and regional operating conditions.

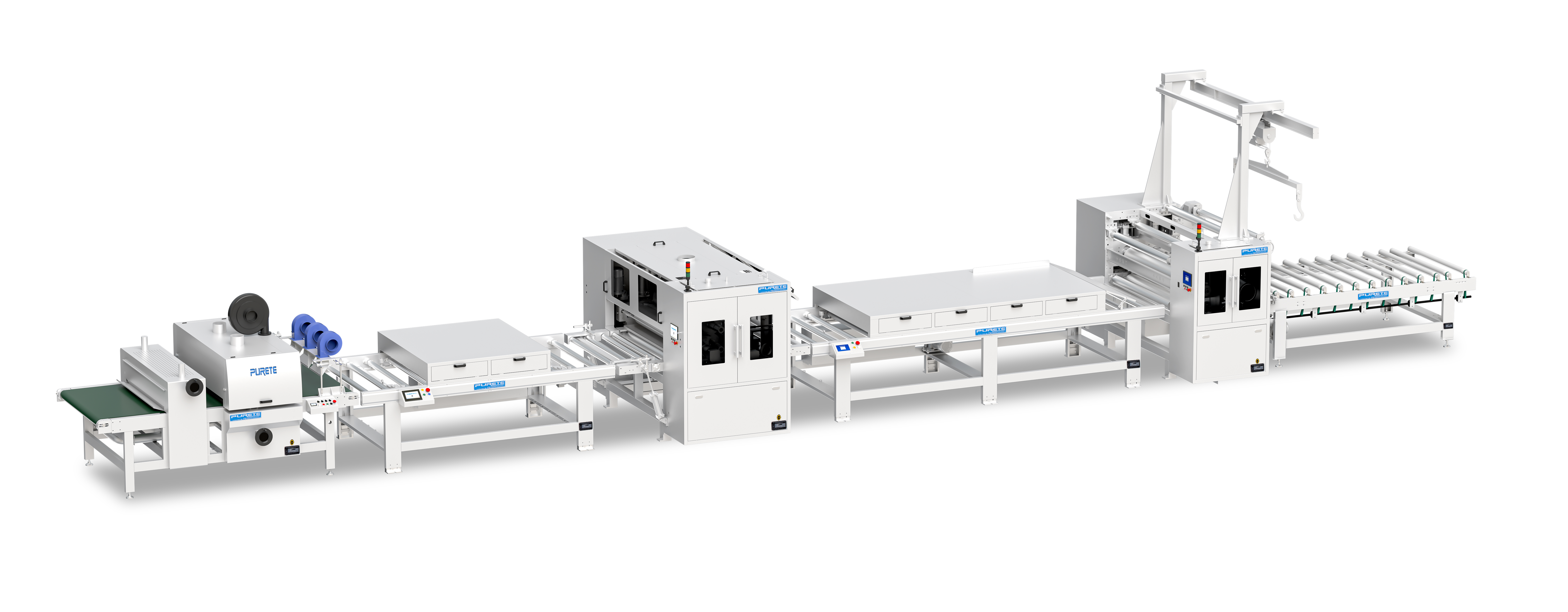

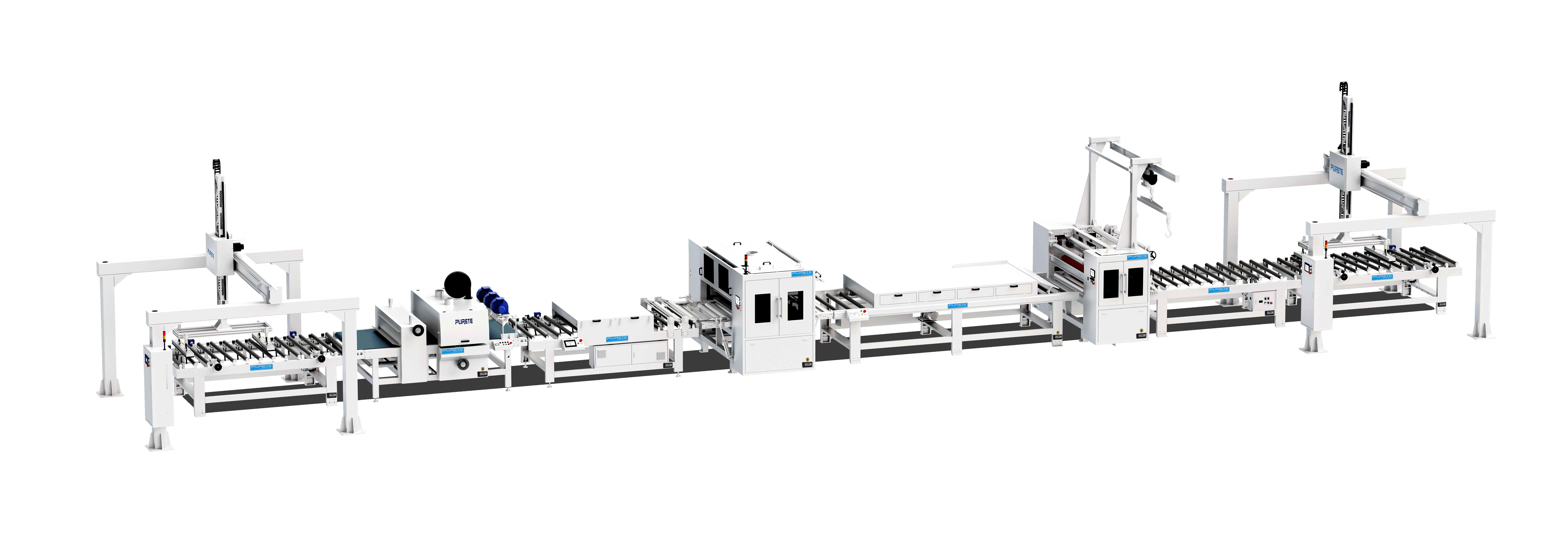

PURETE Offers Customizable PUR Laminating Production Lines for Continuous Industrial Operation

At PURETE, we provide customizable PUR laminating production lines designed for continuous, industrial-scale operation. Our systems are widely used for PET-G lamination on substrates such as calcium silicate board, acoustic panels, particleboard, metal sheets, acrylic panels, and aluminum honeycomb structures.

We focus on delivering:

Stable PUR adhesive application at high speed

Reliable lamination quality across diverse materials

Line configurations adapted to regional production environments

Our PUR laminating lines are well suited for manufacturers targeting Algeria and broader African markets, where durability, efficiency, and long-term reliability are essential. By tailoring system design to real production conditions, we help customers achieve consistent results and scalable growth.

Conclusion

A PUR laminating production line is a proven solution for manufacturers seeking durable, high-quality lamination across a wide range of materials. With PET-G films and PUR adhesive technology, these lines deliver superior bonding strength, environmental resistance, and surface consistency.

For industries serving Algeria and other African markets, PUR lamination offers a reliable way to meet climate challenges while maintaining modern design standards. By selecting a well-designed, customizable solution from PURETE, manufacturers can build efficient, future-ready lamination operations that support long-term industrial success.