Why PUR Laminating Production Lines Are Becoming Essential in High-End Furniture Manufacturing

December 17, 2025

December 17, 2025 Hits:171second

Hits:171secondIn the high-end furniture market, surface quality has evolved from a functional requirement into a defining element of brand value. Consumers increasingly associate premium furniture with seamless edges, refined textures, and long-lasting finishes that maintain their appearance under daily use. As a result, manufacturers are under growing pressure to adopt advanced surface laminating technologies that go beyond traditional solutions.

Conventional laminating methods based on EVA adhesives or basic wrapping equipment often struggle to deliver the durability and visual precision required for premium furniture products. Issues such as edge lifting, visible glue lines, and poor resistance to heat or moisture can quickly undermine perceived quality.

Against this backdrop, PUR laminating production lines are becoming a standard choice in high-end furniture manufacturing. By combining polyurethane reactive adhesive technology with automated laminating systems, PUR lamination offers superior bonding strength, enhanced environmental resistance, and a true zero-edge appearance. These advantages make PUR laminating not just an upgrade, but a strategic investment for manufacturers targeting the premium segment.

What Is PUR Laminating?

PUR laminating is a surface bonding process that uses polyurethane reactive hot melt adhesive to laminate decorative materials onto furniture substrates. Common laminating materials include PVC films, PET foils, acrylic sheets, decorative papers, and natural wood veneers.

Unlike conventional hot melt adhesives that rely mainly on cooling to achieve bonding strength, PUR adhesive reacts chemically with moisture in the air and within the substrate after application. This reaction forms a highly durable cross-linked structure, significantly improving long-term adhesion and resistance to environmental stress.

Because of this chemical bonding mechanism, PUR lamination is widely used in high-end furniture surface finishing, decorative panel wrapping, and premium board lamination applications where appearance and durability are equally important.

Why Furniture Manufacturers Choose PUR Laminating

Strong Adhesion to Challenging Surfaces

Modern furniture design increasingly incorporates high-gloss films, coated boards, composite panels, and engineered wood materials. These surfaces can be difficult to bond using traditional laminating technologies.

PUR bonding technology offers:

Reliable adhesion on MDF, HDF, and composite substrates

Strong bonding to low-surface-energy decorative films

Stable performance on complex and coated surfaces

This makes PUR laminating systems especially suitable for premium furniture components that demand long-term structural integrity.

High Heat and Moisture Resistance

Furniture used in kitchens, bathrooms, and commercial interiors must withstand humidity, temperature fluctuations, and frequent cleaning. Once fully cured, PUR adhesive delivers excellent resistance to both heat and moisture.

Compared with traditional EVA-based laminating, PUR lamination provides:

Improved thermal stability

Reduced risk of glue softening

Long-term resistance to moisture-related delamination

These properties significantly extend the service life of finished furniture products.

Zero-Edge Appearance and Visual Refinement

High-end furniture design increasingly favors minimalist aesthetics, where visible glue lines or uneven edges are unacceptable. PUR laminating enables a zero-edge or near-invisible joint appearance, thanks to its extremely thin and consistent glue line.

This allows manufacturers to achieve:

Seamless transitions between panels and decorative layers

Clean, modern visual effects

Higher perceived product quality

For premium furniture brands, this visual improvement is often a decisive factor.

PUR Laminating Production Line Structure

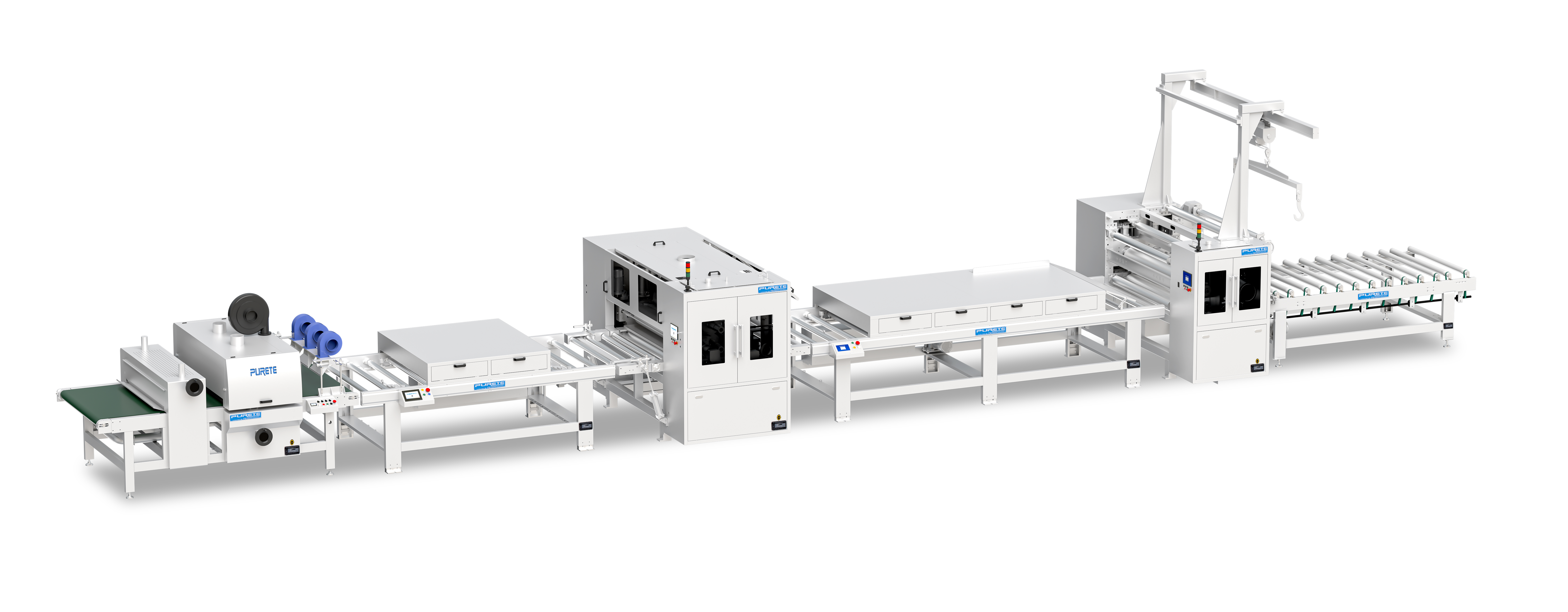

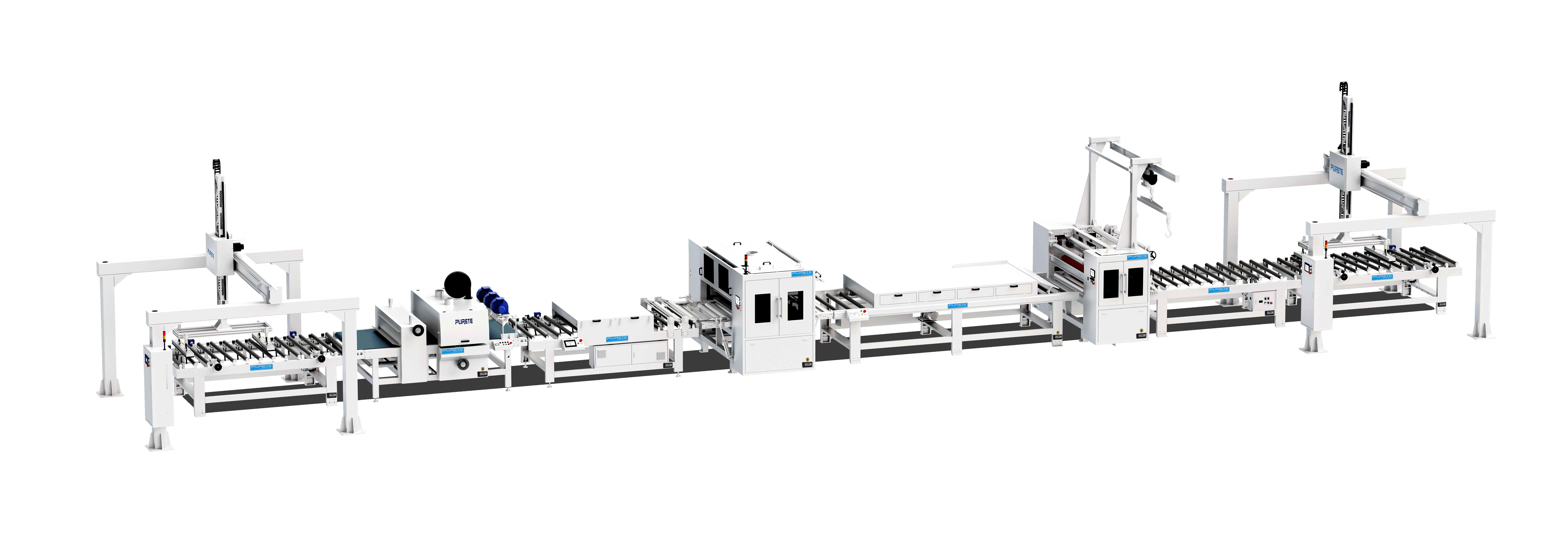

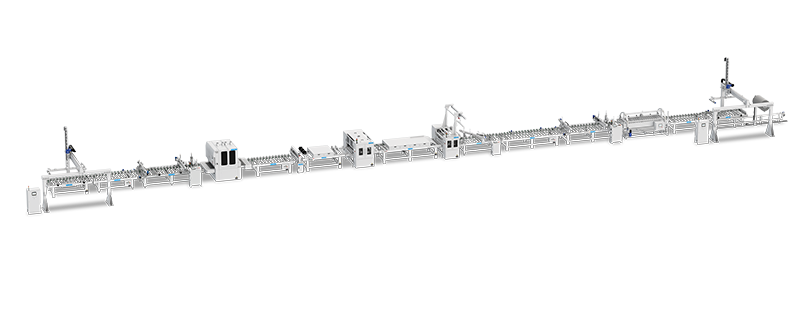

A modern PUR laminating production line consists of multiple coordinated units designed to ensure precise, stable, and repeatable laminating performance.

Glue Application Unit

The glue application unit is responsible for applying PUR adhesive evenly and accurately to the substrate surface. Precise control of temperature, coating thickness, and application width is essential to ensure consistent bonding quality and efficient adhesive usage.

This unit directly affects:

Bonding strength

Surface uniformity

Material consumption control

Preheating and Laminating Unit

Preheating improves adhesive activation and enhances bonding performance, especially for dense or coated panels. The laminating unit then applies controlled pressure to bond the decorative material to the substrate.

This stage ensures:

Proper adhesive wetting

Stable initial bonding

Accurate alignment of films or veneers

Cutting, Trimming, and Pressing Components

After lamination, cutting and trimming components remove excess material and refine edges. Pressing elements help stabilize the bond during early curing, contributing to consistent dimensions and surface flatness.

These processes are critical for achieving premium finishing results.

Benefits for High-End Furniture Production

From a production perspective, PUR laminating production lines deliver a combination of functional, aesthetic, and operational benefits:

Long-term bonding durability

Excellent resistance to heat and humidity

Premium surface and edge quality

Reduced risk of after-sales defects

Stable performance for continuous production

For manufacturers focused on upscale markets, these benefits directly support brand positioning and customer satisfaction.

Typical Applications

Furniture Boards and Laminated Panels

PUR laminating is widely used for flat furniture boards and decorative laminated panels, providing smooth surfaces and consistent visual quality.

Doors, Wardrobes, and Kitchen Cabinets

Cabinet doors and storage furniture benefit from PUR lamination's moisture resistance and zero-edge appearance, particularly in kitchens and bathrooms.

Decorative Wall Panels and Interior Components

Decorative wall panels and interior furniture elements require strong adhesion and refined finishes, making PUR laminating systems an ideal solution.

PURETE's PUR Laminating Solutions

At PURETE, we develop PUR laminating production lines with a clear focus on real furniture manufacturing requirements. Our approach emphasizes process stability, precise control, and adaptability across different product categories.

Our PUR laminating solutions are designed to:

Support consistent PUR hot melt lamination processes

Work with commonly used furniture substrates and decorative films

Integrate smoothly into automated furniture production environments

By prioritizing reliable operation and flexible system configuration, PURETE helps manufacturers apply PUR laminating technology effectively, whether for standard panel production or high-end customized furniture components.

Conclusion

PUR laminating production lines are becoming an essential part of high-end furniture manufacturing, offering superior bonding strength, excellent environmental resistance, and refined surface aesthetics. As quality expectations continue to rise, PUR lamination provides manufacturers with a proven and scalable solution for premium surface finishing.

With professional PUR laminating solutions from PURETE, furniture manufacturers can enhance product durability, achieve zero-edge visual standards, and strengthen their competitiveness in the premium furniture market.