Tips to Choose the Automatic Paint Spraying Machine for Your Business

June 16, 2025

June 16, 2025 Hits:556second

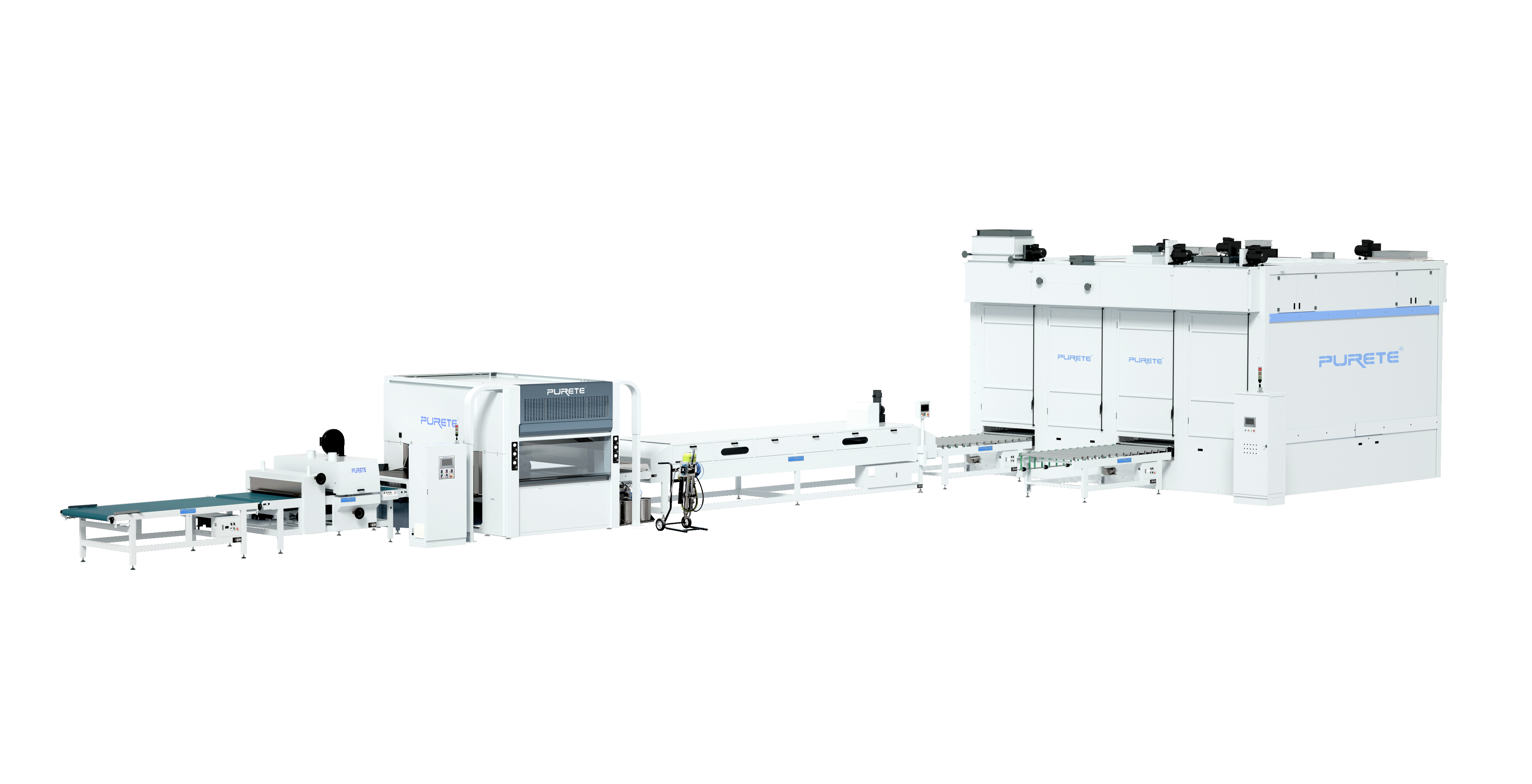

Hits:556secondSelecting the right automatic paint spraying machine is a pivotal decision for any business seeking to improve coating efficiency, product quality, and operational scalability. As the manufacturing landscape evolves, the demand for advanced, flexible, and environmentally responsible automatic spray painting equipment continues to rise. PURETE, as an industry leader, not only provides standard automatic spraying solutions but also specializes in innovative systems such as five-axis spray machines and paper belt spray lines, along with tailored customization services to meet unique production needs. This guide will help you navigate the key considerations and features to look for when choosing the optimal automatic paint spraying system for your business.

Assessing Your Business Needs

The first step in choosing an automatic paint spraying machine is to thoroughly evaluate your production requirements and operational goals. Consider the following:

Product Types and Materials: Identify whether your primary focus is on furniture, flooring, cabinetry, wardrobes, wooden doors, or decorative moldings. Each product category may require specific spraying techniques and machine capabilities. PURETE's machines are engineered to handle a wide range of substrates, including wood, metal, glass, and plastic.

Production Scale and Workflow: Assess whether you need a high-throughput, continuous automatic spray line or a more flexible, batch-oriented system. For instance, five-axis spray machines are ideal for complex shapes and high-value products, while paper belt conveyor systems excel in large-scale, flat-panel production.

Desired Finish and Quality: Define the finish quality you expect, such as uniform color and texture across all five sides of the workpiece. Advanced automatic spray painting machines ensure consistent, high-quality results that meet industry standards.

Coating Materials: PURETE's equipment is compatible with a variety of coatings, including UV paint, water-based UV, water-based paint, and PU coatings. Confirm that your chosen system supports your preferred materials for optimal adhesion and durability.

Space and Integration: Evaluate your factory layout and determine how the new equipment will integrate with your existing production lines, conveyors, and finishing stations.

Key Features to Look for in an Automatic Paint Spraying Machine

When comparing automatic paint spraying machines, prioritize the following features to maximize performance, flexibility, and long-term value:

Advanced Atomization Technology: Look for systems equipped with high-pressure spray guns, rotary cup atomizers, or reciprocating arms. These technologies ensure fine atomization and even paint distribution, resulting in smooth, flawless finishes.

Multi-Surface and Five-Axis Capability: Machines with five-axis motion can coat complex geometries and multiple surfaces in a single pass, improving efficiency and reducing the need for manual touch-ups. This is especially valuable for intricate furniture components, doors, and decorative panels.

Automated Control and Precision: Digital control panels, programmable settings, and sensor-based product recognition allow for precise adjustment of spray parameters, ensuring repeatable, high-quality results and minimizing material waste.

Versatility and Adaptability: Choose equipment that can accommodate a variety of workpiece sizes, shapes, and materials. PURETE's solutions are designed for flexibility, supporting everything from small decorative moldings to large doors and panels.

Efficient Material Handling: Paper belt conveyor systems and antistatic feed belts streamline the movement of workpieces, reduce contamination, and simplify cleaning, making them ideal for continuous production environments.

Easy Maintenance and Fast Color Change: Modular designs, automatic lubrication, and quick-change paint systems minimize downtime and maintenance costs, supporting higher productivity and responsiveness to changing production demands.

Safety and Environmental Compliance: Ensure the system includes robust ventilation, overspray capture, and VOC reduction features. PURETE’s machines are engineered to minimize emissions and support compliance with environmental regulations.

Customization Options: Every business has unique requirements. PURETE offers comprehensive customization services, allowing you to tailor your automatic spray painting equipment to specific production needs, coating types, and workflow integration.

Energy Efficiency and Environmental Impact

Modern automatic paint spraying machines are designed with sustainability and cost-efficiency in mind:

Optimized Paint Usage: Advanced atomization and precise control reduce paint waste, directly lowering material costs and environmental impact.

VOC and Emission Reduction: Systems are built to work with low-VOC paints and include multi-stage filtration and exhaust systems to capture overspray and minimize harmful emissions.

Energy-Efficient Operation: Features such as inverter-controlled fans, automated shut-offs, and efficient conveyor systems help lower energy consumption and operating costs.

Clean Production Environment: Paper belt conveyors and enclosed spray booths maintain a dust-free environment, reducing the risk of defects and improving overall finish quality.

Why PURETE Is Your Best Partner for Automatic Paint Spraying Machine Solutions

PURETE distinguishes itself as a trusted automatic production line provider of advanced automatic paint spraying solutions for modern manufacturing:

Comprehensive Product Range: From standard automatic spray machines to specialized five-axis systems and paper belt conveyor lines, PURETE covers the full spectrum of industrial coating needs.

Industry Versatility: Our equipment is widely used in the production of furniture, flooring, cabinets, wardrobes, wooden doors, and decorative moldings, supporting both solid wood and composite materials.

Broad Coating Compatibility: PURETE machines are engineered for use with UV, water-based UV, water-based, and PU coatings, ensuring flexibility for your evolving production requirements.

Customization Services: We understand that every business is unique. PURETE provides tailored solutions, adjusting machine specifications, spray technology, and integration features to match your exact needs.

Process Automation and Digital Control: Our systems feature intuitive touch-screen interfaces, programmable logic controllers, and real-time monitoring for precise process control and easy operation.

Sustainability Commitment: PURETE prioritizes environmental responsibility, integrating features that minimize emissions, reduce paint consumption, and support green manufacturing practices.

Comprehensive Support: From initial consultation and equipment selection to installation, training, and after-sales service, PURETE offers end-to-end support to ensure your operations run smoothly and efficiently.

Conclusion

Selecting the optimal automatic paint spraying machine is a strategic investment that can transform your business's productivity, product quality, and sustainability. By carefully assessing your unique requirements, prioritizing advanced features, and considering energy efficiency and environmental impact, you can make an informed decision that supports both immediate and long-term growth. PURETE's innovative solutions—including five-axis spray machines, paper belt conveyor systems, and fully customized equipment—position your business at the forefront of modern coating technology. Trust PURETE to deliver the expertise, flexibility, and reliability you need for superior coating performance and operational excellence.