Why PUR Laminating Machines Are Essential for Advanced Surface Finishing

November 19, 2025

November 19, 2025 Hits:264second

Hits:264secondAs global demand for high-quality decorative surfaces continues to grow, manufacturers across the furniture, woodworking, and interior materials industries are upgrading their production lines with more advanced bonding technologies. Among these, PUR laminating machines—powered by reactive polyurethane hot melt adhesive (PUR glue)—have become a cornerstone for achieving superior surface bonding, long-term durability, and aesthetic precision.

Unlike traditional EVA hot melt systems, PUR laminating technology delivers stronger adhesion, moisture resistance, heat stability, and exceptional bonding performance for a wide range of substrates. For companies aiming to enhance product quality, improve production efficiency, and stay competitive in high-demand sectors, PUR laminators have become essential equipment.

This article takes an in-depth look at how PUR laminating machines work, the advantages of PUR bonding, key applications in modern manufacturing, and the factors to consider when choosing an efficient PUR laminating system. You will also learn why many manufacturers prefer reputable industry suppliers such as PURETE, known for providing reliable laminating and coating solutions for industrial production.

Understanding PUR Laminating Technology

What Is a PUR Laminating Machine?

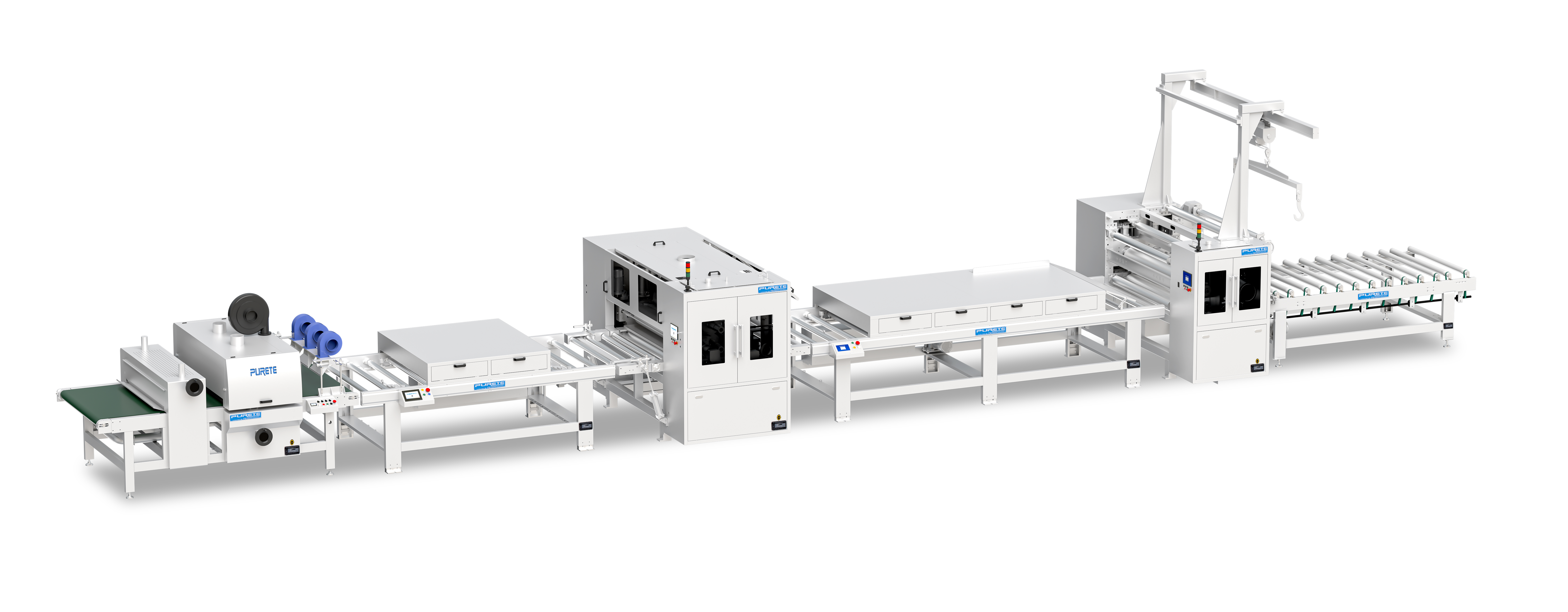

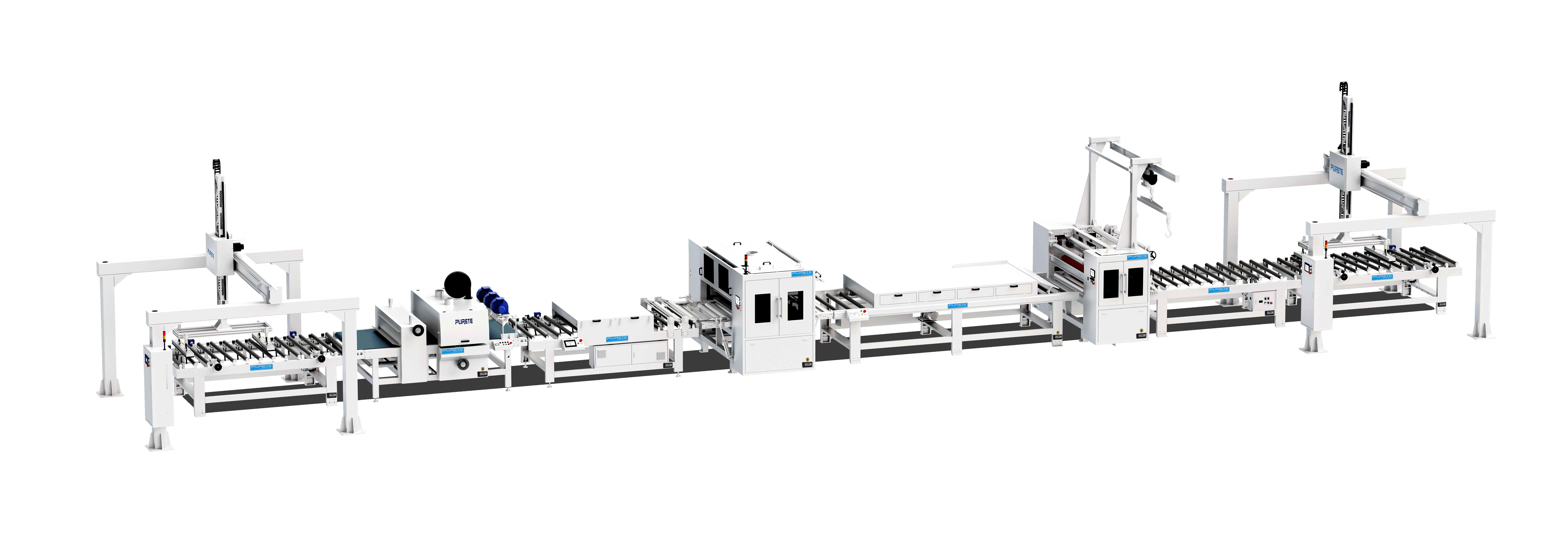

A PUR laminating machine is an industrial system designed to apply PUR reactive hot melt adhesive onto substrates such as MDF, particle board, plywood, PVC film, PET film, veneer, aluminum profiles, and composite materials. After application, the machine bonds decorative films or sheets onto the substrate under controlled pressure and temperature.

Key components typically include:

PUR melting unit / tankless melting system

Precision glue application head or roller system

Heating and temperature control system

Laminating press or roller press

Film unwinding and tension control unit

Cooling and trimming section

Intelligent PLC control system

What makes PUR laminating machines unique is the use of polyurethane reactive adhesive, which chemically reacts with ambient moisture to form a permanent, high-strength bond.

Key Process Features and Materials Used

PUR laminating technology supports a wide range of materials, including:

PVC decorative films

PET high-gloss films

Acrylic sheets

Veneer sheets

CPL and HPL laminates

Melamine paper

Aluminum foil film

Composite substrates

The process typically involves:

Heating the PUR adhesive to a liquid state for application.

Coating the substrate or film using a roller or slot nozzle.

Laminating the film onto the substrate with pressure rollers.

Bonding and curing, where PUR undergoes chemical cross-linking.

Cooling and trimming to complete the finished panel.

This reactive bonding structure ensures exceptional durability—one of the main reasons PUR laminators have become indispensable for advanced finishing lines.

Advantages of PUR Laminating Machines

1. Strong Adhesion and Durable Finish

PUR adhesive is known for its extremely high bonding strength, outperforming traditional EVA glue in almost every aspect. Key benefits include:

Long-lasting adhesion

Heat and moisture resistance

Excellent dimensional stability

No delamination, even under extreme conditions

Strong bonding with difficult substrates

This is why PUR is widely used in high-end furniture products, kitchen cabinets, interior decorative boards, and bathroom panels that must withstand temperature variations and humidity.

2. Compatibility with Various Materials

One of the biggest advantages of PUR laminating machines is their wide compatibility with diverse materials. Unlike conventional lamination processes that struggle with high-gloss film, PET, or composite panels, PUR supports:

High-gloss and super matte PET films

PVC lamination films

Wood veneer sheets

Metallic foils

Aluminum panels

Plastic components

Curved or complex-shaped surfaces (depending on machine design)

This flexibility allows manufacturers to expand their product portfolio and meet the growing demand for premium decorative surface solutions.

3. Reduced Production Time

PUR laminating machines are engineered for continuous, high-speed production, enabling manufacturers to achieve:

Faster bonding

Shorter processing cycles

Reduced drying time (PUR does not require extended curing)

Efficient heat transfer

Smooth integration into automated lines

Compared with solvent-based or cold-glue systems, PUR allows products to be processed immediately after lamination, significantly shortening lead times.

4. Superior Surface Quality and Visual Appearance

Because PUR is a high-performance adhesive, the resulting laminated panels achieve:

Flawless surface finish

No bubbling or peeling

Precise edging and wrapping

Minimal glue lines

High resistance to fingerprints (especially with matte PET films)

This level of quality is essential for manufacturers targeting high-end markets such as luxury furniture, premium doors, modern interior décor, and advanced commercial-grade panels.

Applications in Modern Manufacturing

1. Furniture Industry

In the global furniture industry, PUR laminating machines are used extensively for:

Cabinet panels

Doors

Wardrobes

Bathroom furniture

Office furniture

Wall shelves

Drawer fronts

High-gloss and matte PET films have become popular design trends, and PUR technology ensures the surface remains:

Scratch resistant

Moisture resistant

Smooth and defect-free

PUR lamination is essential for manufacturers producing premium-quality furniture for export markets.

2. Wood Panels and Laminates

Wood panel manufacturers increasingly rely on PUR laminating lines to produce:

MDF laminated boards

Particle board decorative panels

SPC/WPC surface lamination

Veneer composite boards

Acoustic wall panels

Decorative interior sheets

The flexibility of PUR adhesive allows panels to withstand temperature fluctuations, making them suitable for kitchens, bathrooms, and commercial interiors.

3. Interior Decoration and Wall Panels

Decorative wall panel production often involves difficult surfaces such as:

Textured films

Ultra-matte surfaces

Metallic or aluminum laminates

Special design PET films

PUR laminating machines help achieve consistent, high-quality finishes while ensuring long-term adhesion.

4. Door Manufacturing Lines

Interior and composite doors require:

Strong bonding

Warp resistance

Smooth decorative finishes

PUR lamination ensures durability and prevents film peeling—an essential factor in door quality.

5. Automotive and RV Components

Certain automotive interiors and RV furniture require lightweight composite panels and decorative laminates. PUR technology is ideal for these applications due to:

Strong bonding

Vibration resistance

Heat stability

This makes PUR laminators useful for specialized transportation and mobility production segments.

Choosing the Right PUR Laminating Machine for Your Production Line

Selecting a PUR laminating machine requires careful evaluation of production needs, materials, and quality requirements. Here are key factors to consider:

1. Machine Configuration and Capabilities

Evaluate whether the machine supports:

Required working width

Desired application methods (roller coating or slot nozzle)

Type of films (PVC, PET, veneer, CPL, aluminum foil)

Continuous or batch lamination

Required heating and temperature controls

Feeding and unwinding system stability

Integration with existing production lines

Advanced manufacturers offer modular solutions that allow businesses to expand production capacity without replacing the entire system.

2. Automation Level and Process Control

A high-quality PUR laminating machine should provide:

PLC automatic control

Precise temperature regulation

Automatic film tensioning

Real-time monitoring

Stable coating thickness

These features ensure consistent output and reduced operational risks.

3. Maintenance and Long-Term Reliability

Choose equipment designed for:

Easy cleaning

Glue-saving structures

Quick replacement of rollers

Durable components

Stable adhesive supply

Long-term machine lifespan

Well-known suppliers provide reliable after-sales service and technical support—critical for maintaining production stability.

4. Supplier Reputation and Industry Experience

When choosing a PUR laminating system, partnering with the right manufacturer is essential. This is why many companies prefer established brands such as PURETE, well known in the industry for:

Professional laminating and coating solutions

Reliable and stable industrial equipment

Well-developed product technology

Integration of complete production line systems

Strong reputation in woodworking and decorative material processing

PURETE's laminating solutions are recognized for quality and durability, making them a trusted partner for manufacturers upgrading to high-end laminating technology.

Conclusion

PUR laminating machines have become essential in advanced surface finishing due to their unmatched bonding strength, versatility, and efficiency. Whether used in the furniture industry, decorative panel production, or interior finishing materials, PUR technology delivers superior quality, reduces production time, and enhances product durability.

For manufacturers aiming to remain competitive, choosing the right PUR laminating system is a strategic decision that impacts long-term product performance and production stability. Working with reliable suppliers—such as PURETE, known in the market for providing high-standard laminating and coating equipment—ensures consistent output and dependable support.

As demand for modern, durable, and visually appealing surfaces continues to rise, PUR laminating machines will remain a critical technology for manufacturers looking to achieve premium-level finishing quality.